Method and apparatus in connection with a screw compressor

A screw compressor, pressure technology, applied to the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., can solve the problem of taking a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

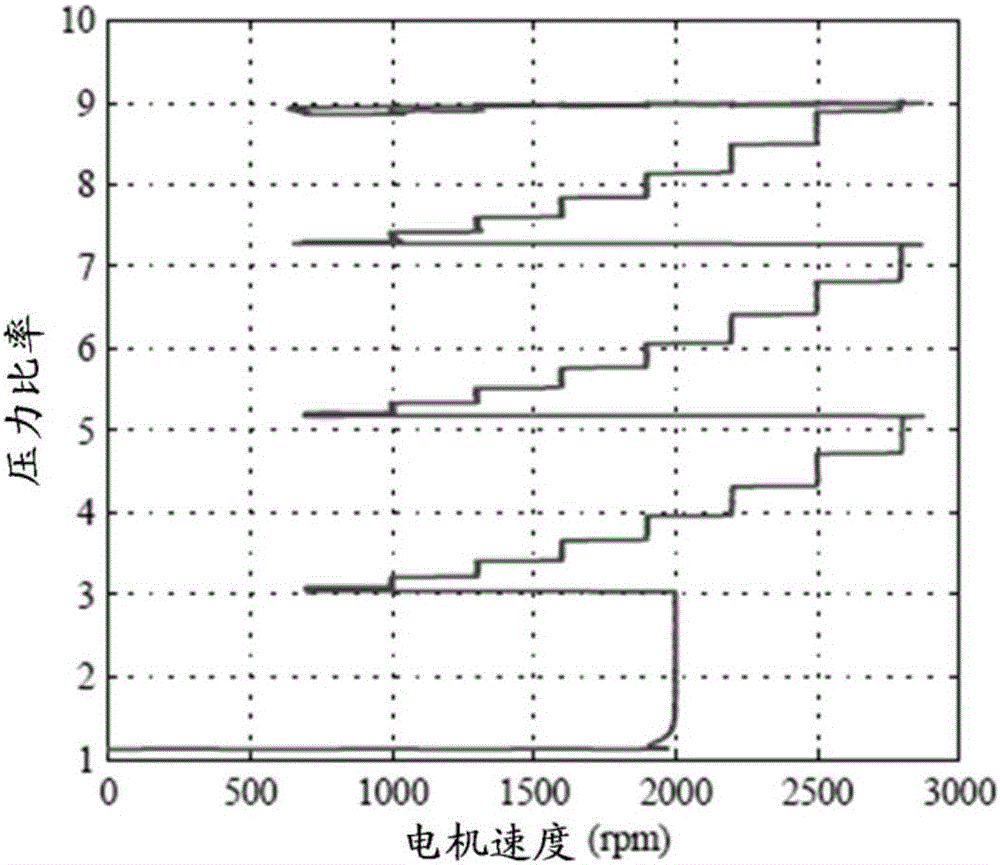

[0015] In the present invention, a screw compressor driver including a screw compressor and a frequency converter is driven by a frequency converter. Frequency converters are known to drive electric motors at variable rotational speeds. In systems associated with the present invention, the output of the frequency converter is connected to an electric motor that rotates a screw compressor to produce pressurized gas.

[0016] Frequency converters typically include a processor with computing capabilities and internal measurements. The measurements relate to eg rotational speed, torque and power. These measurements can be used in the device's processor for further calculations.

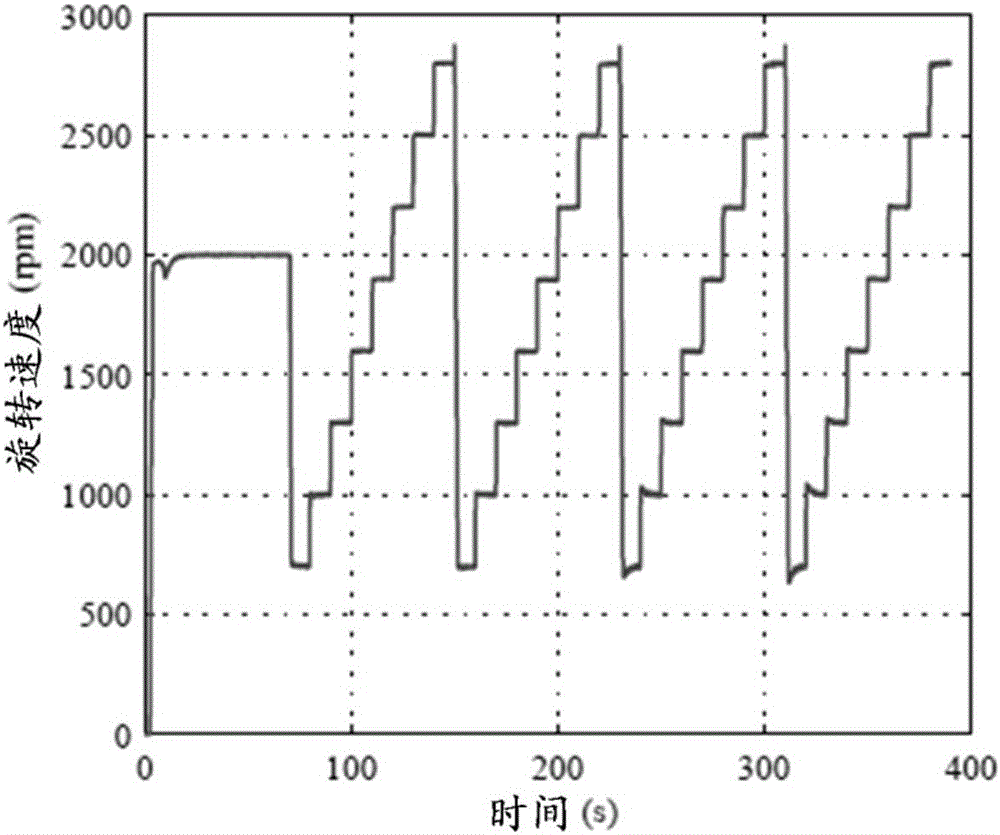

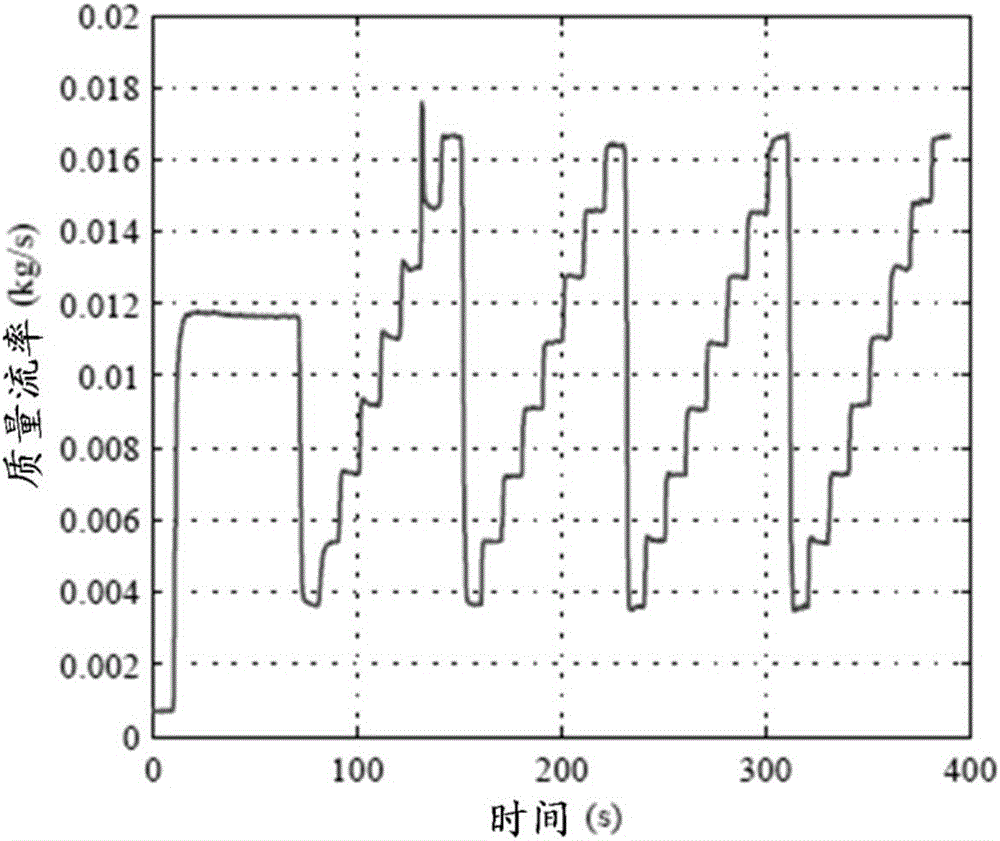

[0017] In the present invention, the pressure vessel of a screw compressor driven by a frequency converter is filled or pressurized. According to an embodiment of the present invention, pressurization is performed using a specific velocity profile that changes velocity in a timed manner. In this speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com