Box-type steel structure girder

A steel structure beam and box technology, applied in the direction of columns, piers, pillars, etc., can solve the problems of shortening the construction period and single structural system, and achieve the effect of shortening the manufacturing period, diversifying the structural system and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

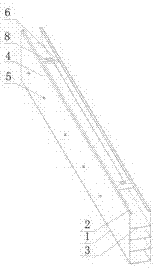

[0039] Such as Figure 1~Figure 3 As shown, a box-type steel structure beam 101 is bent into a U-shaped structure by a steel plate 1 . The upper end of the steel structure beam has an inward flanging 2, and the inside of the steel structure beam 101 is provided with three reinforcing ribs 3. It can be understood that the number of reinforcing ribs 3 can be any integer, which is determined according to the cross-sectional size of the steel structure beam 101. .

[0040] The reinforcing ribs 3 connect the two wall panels 4 of the steel structure beam 101, and multiple reinforcing ribs 3 are parallel to each other.

[0041] Preferably, the reinforcing rib 3 is a steel plate.

[0042] Wind, water and electricity pipelines are housed in the space inside the steel structure beam 101. Specifically, the space formed by the two parallel ribs 3 is equipped with wind, water and electricity pipes; the wall plate 4 of the steel structure beam 101 is provided with a first hole 5 for load...

Embodiment 2

[0045] Such as Figure 4As shown, a box-type steel structure beam 101 is bent into a U-shaped structure by a steel plate 1 . The upper end of the steel structure beam 101 has an inward folded edge 2, and the folded edge 2 is closed so that the steel structure beam 101 forms a box-shaped structure. Three reinforcing ribs 3 are arranged inside the steel structural beam 101 , it can be understood that the number of reinforcing ribs 3 can be any integer, which is determined according to the cross-sectional size of the steel structural beam 101 .

[0046] The reinforcing ribs 3 connect the two wall panels 4 of the steel structure beam 101, and multiple reinforcing ribs 3 are parallel to each other.

[0047] Preferably, the ribs 3 are corrugated boards, specifically, the corrugated boards are profiled boards that are rolled and cold-bent into a plurality of continuous trapezoidal cross-sections.

[0048] Wind, water and electricity pipelines are housed in the space inside the stee...

Embodiment 3

[0050] Such as Figure 5~Figure 8 As shown, embodiment 3 is roughly the same as embodiment 1, and the difference is that: the reinforcing rib 3 is a corrugated plate; the U-shaped bottom of the steel structure beam 101 is provided with a long groove 9, and the groove 9 is provided with evenly distributed connecting plates 10.

[0051] A seal cover 11 is installed below the groove 9, and the seal cover 11 is connected to the connecting plate 10 by bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com