Balance shaft with taper sleeve and for balance fan impeller

A technology of fan impeller and balance shaft, applied in the field of balance shaft, can solve problems such as tolerance matching, and achieve the effect of satisfying the convenience of disassembly and assembly, improving balance quality, and solving the problem of tolerance matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

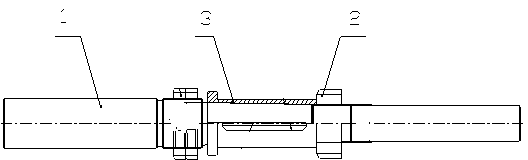

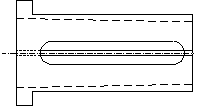

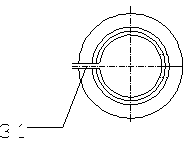

[0022] see Figure 1-3 , the present invention relates to a balancing shaft with a taper sleeve for balancing fan impellers, which includes a main shaft 1, on which a taper sleeve 3 is set, and the taper sleeve 3 is provided with an axial groove 3.1 (see image 3 ), the main shaft 1 is also provided with a locking disk 2, the locking disk 2 is offset against the tail of the taper sleeve 3, and the impeller is installed on the taper sleeve 3.

[0023] Working principle: The taper sleeve 3 and the main shaft 1 have an appropriate amount of interference fit to meet the convenience of installation and reduce the unbalance margin caused by the fit tolerance zone during balance. The taper sleeve 3 has a 2-3mm axial groove 3.1 to ensure The taper sleeve 3 can expand and contract in an appropriate amount, so as to achieve a certain radial adjustment range for the balance shaft, and the tapered self-adaptation after the locking disc 2 is compressed to meet the tolerance of the taper sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com