Ventilation pipe cleaning device

A technology of cleaning device and ventilation duct, applied in the field of ventilation, can solve the problems of difficult metal sheath, inability to clean multiple reciprocating and bent ventilation ducts, and difficulty in cleaning ventilation ducts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

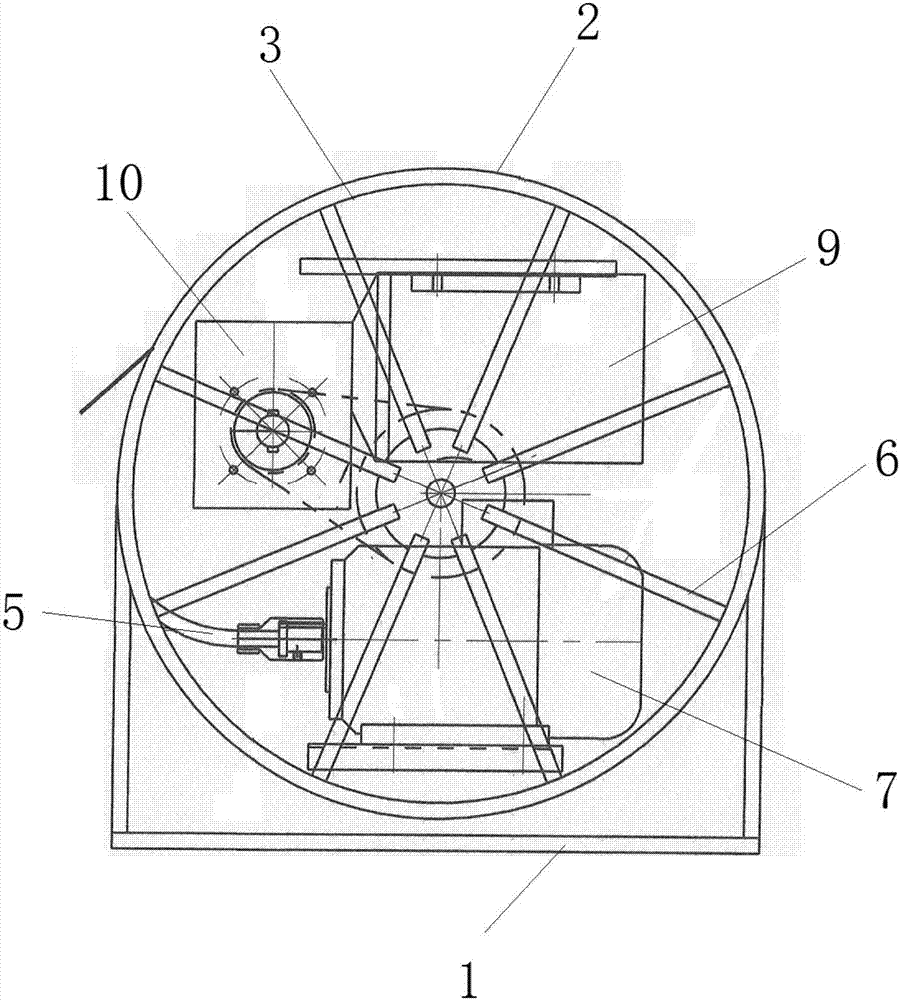

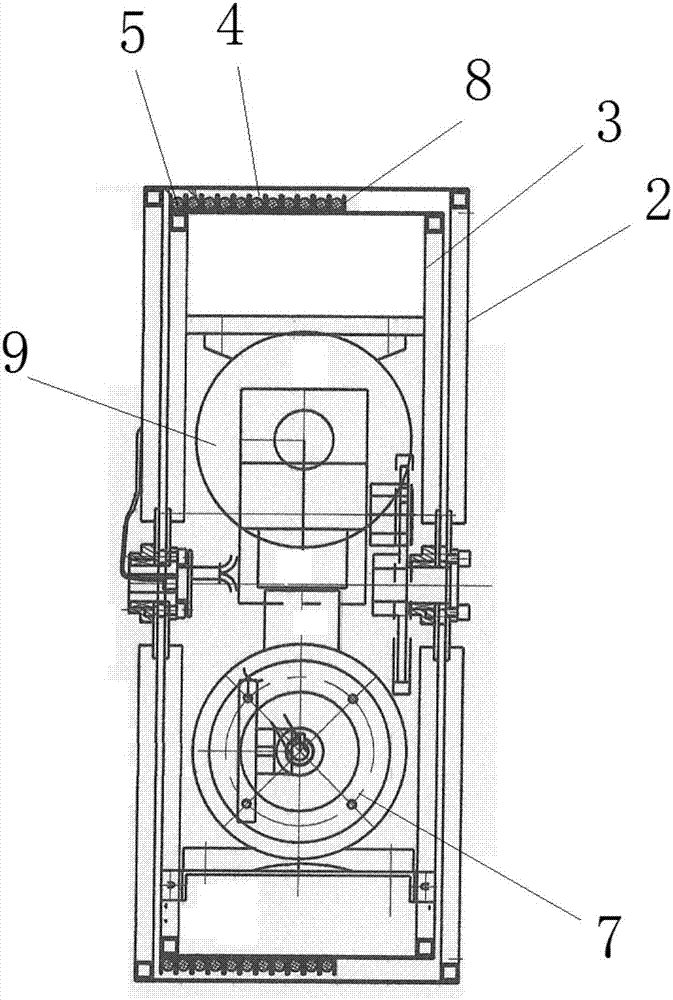

[0029] like Figure 1-2 As shown, a ventilation duct cleaning device provided by an embodiment of the present invention includes a base frame 1, an outer cylinder body 2, an inner cylinder body 3, a flexible shaft 5 and a flexible shaft drive unit 7, and the outer cylinder body 2 is connected to the base on the frame 1; the inner cylinder 3 is sleeved in the outer cylinder 2, which is rotatably connected to the base frame 1, and the outer wall of the inner cylinder 3 is provided with a spiral accommodation groove 4; the flexible shaft 5 Accommodated in the spiral accommodation groove 4, its cleaning end protrudes from the outer side of the outer cylinder 2 through the shaft outlet on the outer cylinder 2, and its driving end passes through the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com