uv curing device for 3d printing products

A technology for curing devices and printing products, which is applied in the direction of processing drive devices, manufacturing auxiliary devices, 3D object support structures, etc., and can solve problems such as uneven UV curing, uneven UV irradiation of 3D products, and affecting the use of 3D products. The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

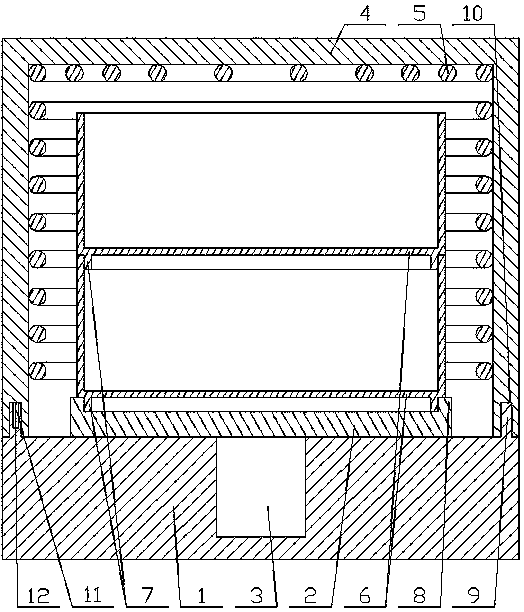

[0034] Such as figure 1It can be seen that the present invention includes a base 1, a tray 2 is arranged above the base 1, and the tray 2 is connected horizontally around a vertical shaft on the base 1, and a cover is provided on the base 1 coaxially with the tray 2 4. The tray 2 is located inside the cover 4, and the inner wall of the cover 4 is provided with a UV lamp 5, and the cover 4 is provided with a fan (not shown in the accompanying drawings), and the fan blows the cover 4 The inside and the outside of the cover 4 are connected, and the tray 2 provides a driving force through the driving motor 3, and the driving motor 3 is fixed in the base 1; the UV lamps 5 are provided with multiple, and the UV lamps 5 are respectively fixed The inner wall of the side wall of the cover 4 and the top inner wall of the cover 4; the UV lamp 5 is a ring lamp, and the center of the UV lamp 5 is located on the straight line where the axis of the tray 2 is located; The UV lamp tubes 5 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com