Curved screen protective film laminating equipment and film laminating method

A bonding equipment and protective film technology, applied in the field of curved screen protective film bonding equipment and film sticking, can solve the problems of difficult precise control of UV irradiation time and distance, endangering the health of operators, and poor artificial film sticking effect, etc., to achieve Stable and consistent product quality, accelerated heat dissipation, and convenient displacement and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

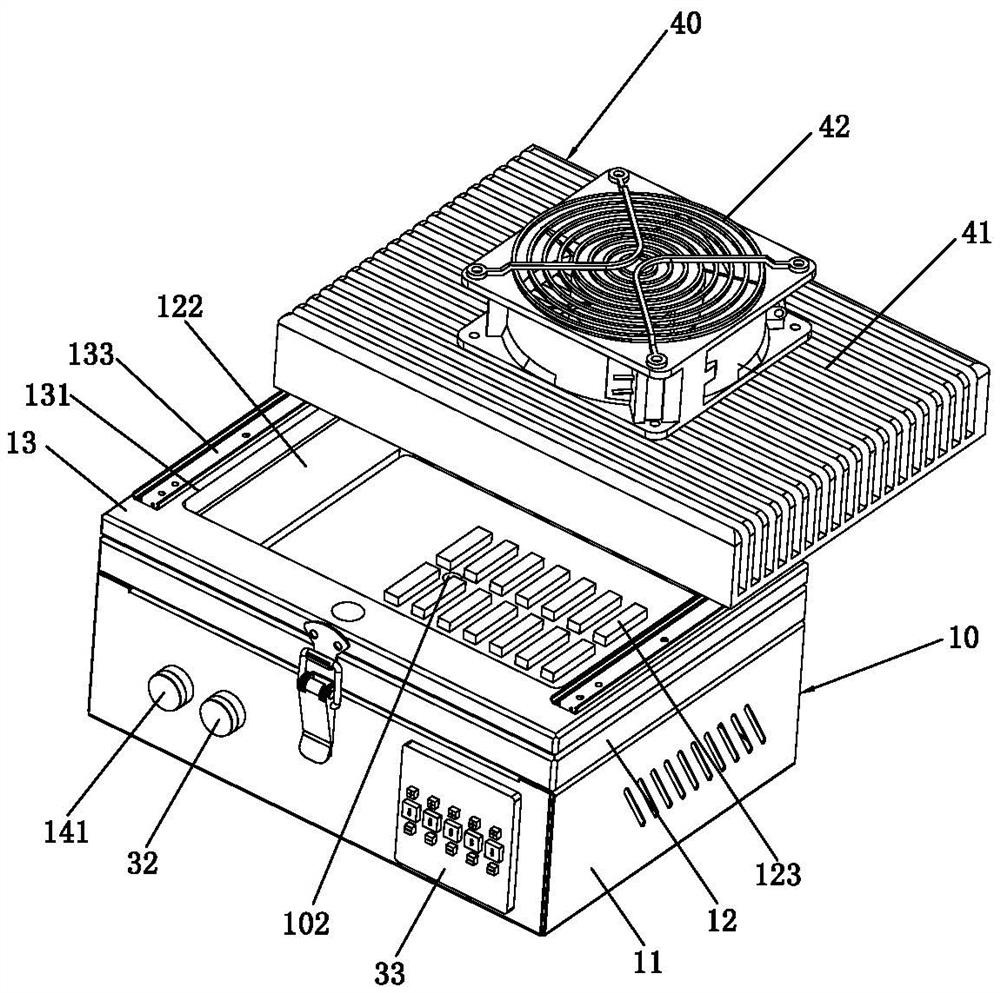

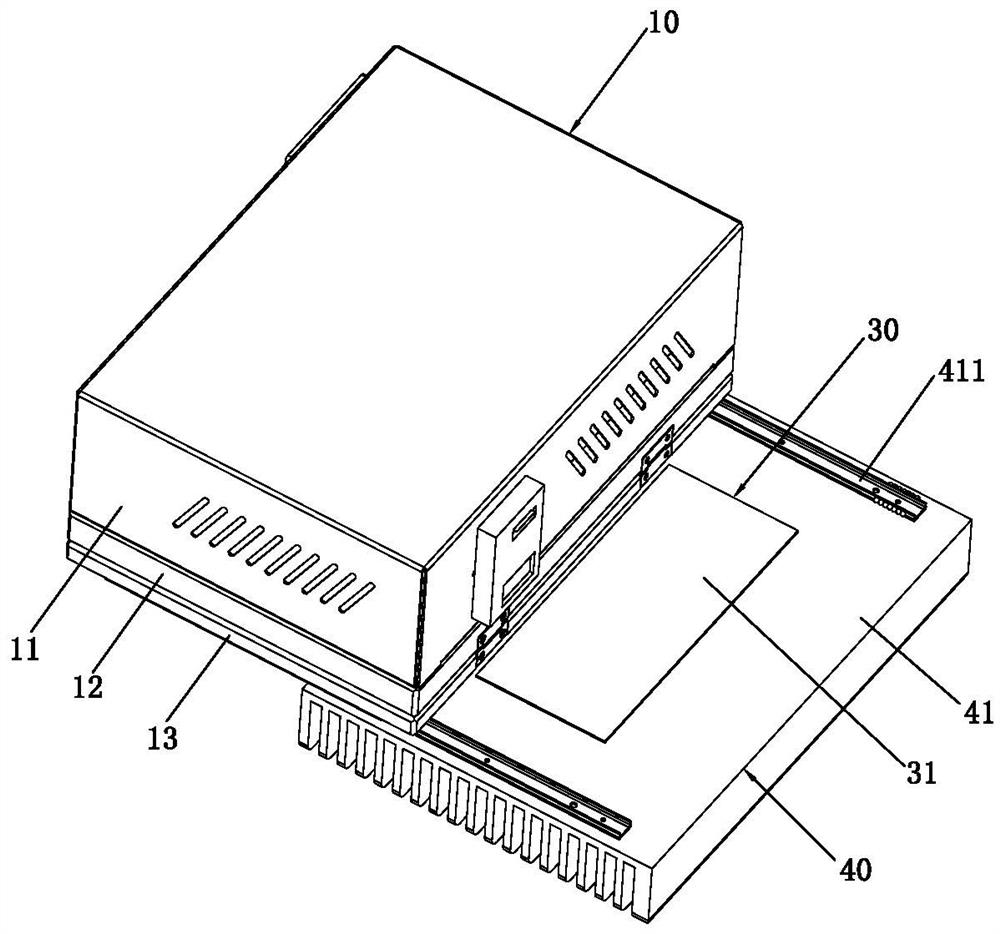

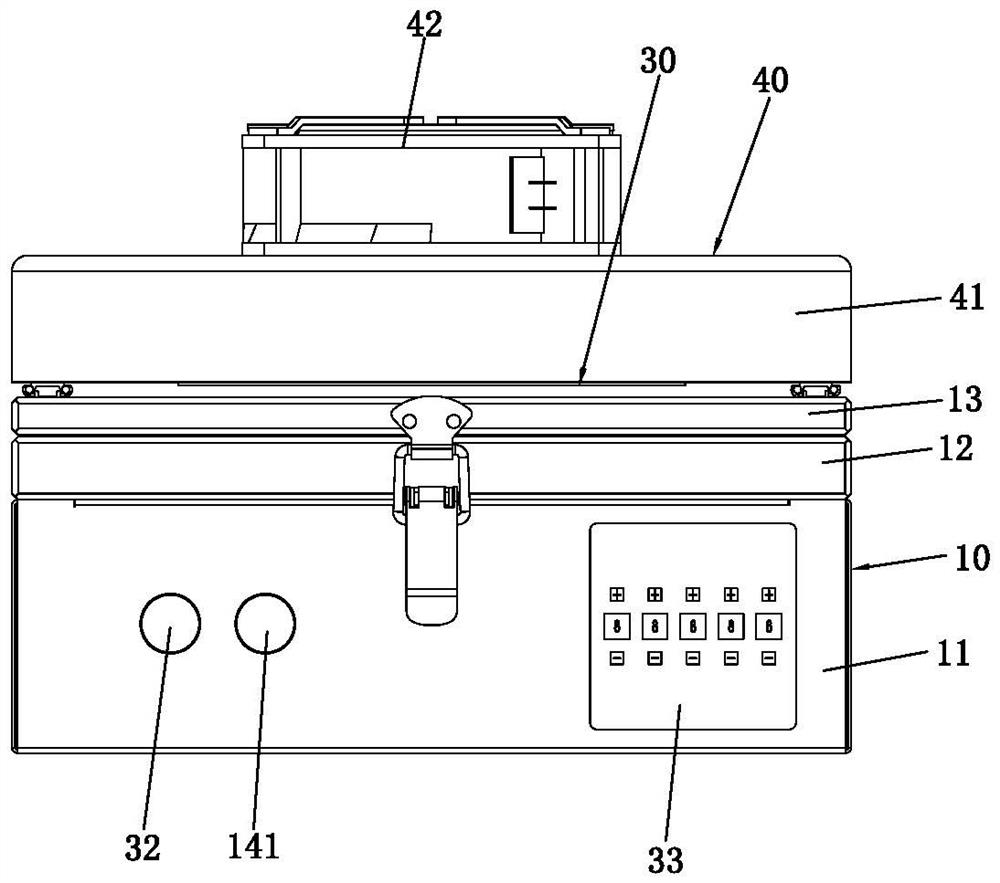

[0041] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of the embodiment of the present invention.

[0042] A curved screen protective film bonding equipment, including a vacuum fixture platform 121, a cover plate 13, a vacuum adsorption device 20, a UV light device 30, and a heat dissipation device 40; wherein:

[0043] The cover plate 13 can be opened and closed on the vacuum fixture platform 121 to form a vacuum cavity 101, and the vacuum suction device 20 is used to vacuum the vacuum cavity 101; the cover plate 13 has an elastic transparent film 132 to Can be deformed toward the vacuum chamber 101; the UV illumination device 30 is arranged above the cover plate 13 to irradiate the vacuum chamber 101 through the elastic light-transmitting film 132, and the heat dissipation device 40 is configured for the UV illumination device 30 to dissipate heat; In this way, through the integrated design of each component, the protective film is pasted on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com