High permeability heat transfer printing machine

A high-permeability, heat-transfer technology, applied to rotary printing machines, printing machines, transfer printing, etc., can solve the problems of increasing blanket covering surface, insufficient penetration rate, and low product quality, so as to improve the printing and dyeing effect Effects on product quality, ink transfer rate increase, and dye penetration rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

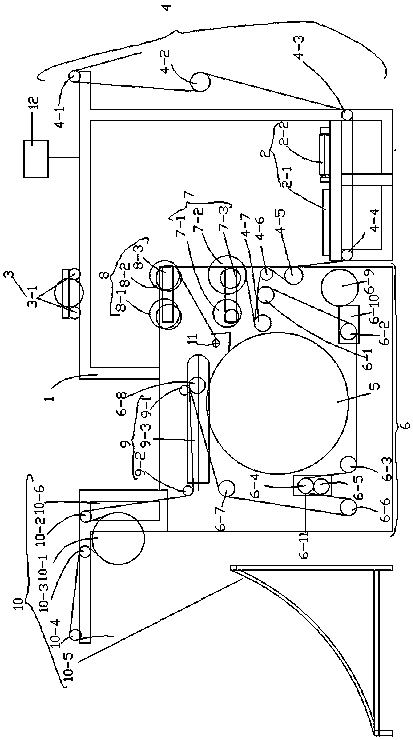

[0031] Embodiment 1: see figure 1Now, a high-permeability thermal transfer printing machine provided by the present invention will be described. The present invention provides the following technical solutions: a high-permeability thermal transfer printing machine, including a heat roller 5, a frame 1, an operating device 2, a cloth feeding device 7 and a tensioning system 6, wherein the heat roller 5 is set Inside the frame 1, the frame 1 is provided with an operating device 2, the operating device 2 includes an operating platform 2-1 and a carriage 2-2, and the cloth feeding device 4 is arranged on the right side of the carriage 2-2 , the cloth feed device 4 consists of the first cloth feed roller 4-1, the second cloth feed roller 4-3, the third cloth feed roller 4-4, the fourth cloth feed roller 4-6 and the fifth cloth feed roller arranged in sequence Cloth rollers 4-7, the tensioning system 6 is composed of tensioning rollers, the first tensioning roller 6-1, the second t...

Embodiment 2

[0032] Example 2: see figure 1 , as an improvement of the present invention, the high-permeability thermal transfer printing machine also includes a paper feeding device 7 and a paper delivery device 8, and the paper feeding device 7 includes a first paper feeding roller 7-1 and a second paper feeding roller 7-1 Roller 7-2, the paper delivery device 8 includes a first paper delivery roller 8-1 and a second paper delivery roller 8-2. The paper feeding device 7 and the paper receiving device 8 are ingenious in design, simple and clear in structure, and are closely connected with each component without interfering with each other, making it easy to maintain the product during use in the future.

Embodiment 3

[0033] Embodiment 3: see figure 1 , as an improvement of the present invention, the first paper feed roller 7-1 and the second paper feed roller 7-2 are fixed on the frame 1 through the first fixing bracket 7-3, and the first The paper delivery roller 8-1 and the second paper delivery roller 8-2 are fixed on the frame 1 through the second fixed frame 8-3. Fixing the paper feeding device 7 and the paper delivery device 8 on the frame 1 through the fixed frame can significantly improve the working stability of the thermal transfer printing machine. In the actual production process, the transfer paper is very heavy. Then in uninterrupted work, the fixed frame can improve the working stability of the paper feeding device 7 and the paper delivery device 8, ensuring the safety of the working environment of the operator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com