Dispersing type conveying mechanism for tablet packer

A conveying mechanism and packaging machine technology, which is applied in the directions of packaging, transportation and packaging, and types of packaging items, can solve the problems of increasing production costs, single transmission belt, and difficulty in decentralized processing, so as to improve production efficiency and improve The effect of practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] In order to make the technical means, creative features, objectives and beneficial effects achieved by the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

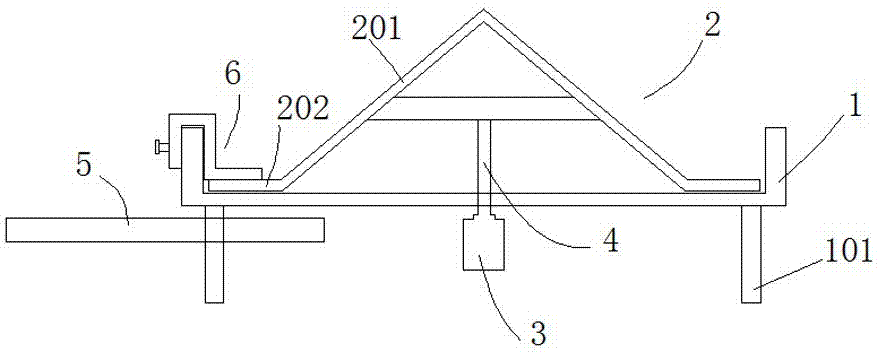

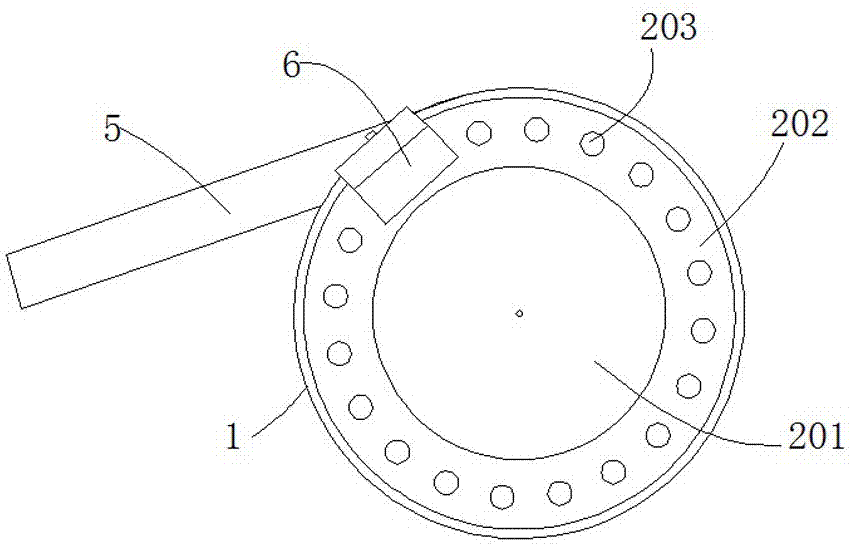

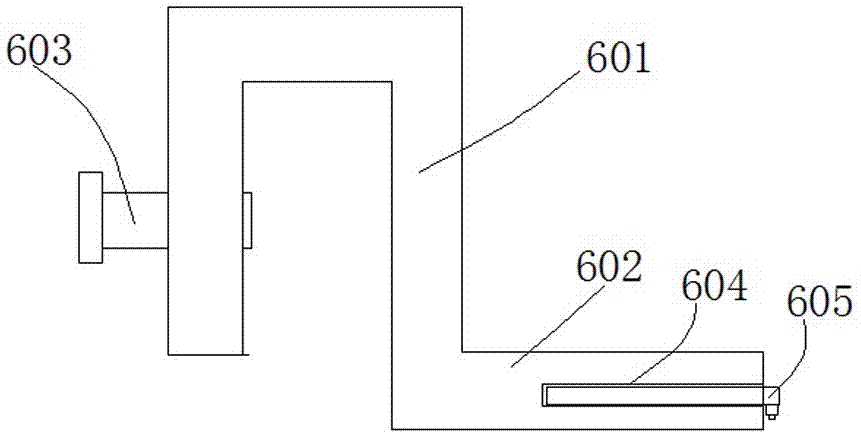

[0020] As shown in the figure, a distributed conveying mechanism for a tablet packaging machine includes a cylindrical receiving trough 1 and a bracket 101 for supporting the receiving trough. The receiving trough 1 is provided with a distribution The mechanism 2 is also provided with a driving mechanism 3 for driving the material distributing mechanism 2 to rotate in the material receiving groove 1. The power shaft of the driving mechanism 3 is connected to the material distributing mechanism 2 through a rotating shaft 4. The through hole for the dropped tablets is located below the through hole with a conveyor belt 5 for receiving and transferring the tablets;

[0021] The said distributing mechanism 2 is composed of a conical distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com