A bulk material flow measuring device

A flow measurement device and bulk material technology, which is applied in the direction of measurement device, measurement flow/mass flow, liquid/fluid solid measurement, etc., can solve problems such as measurement failure, resistance increase, and influence on measurement results, so as to improve reliability and avoid The effect of hanging and measuring accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

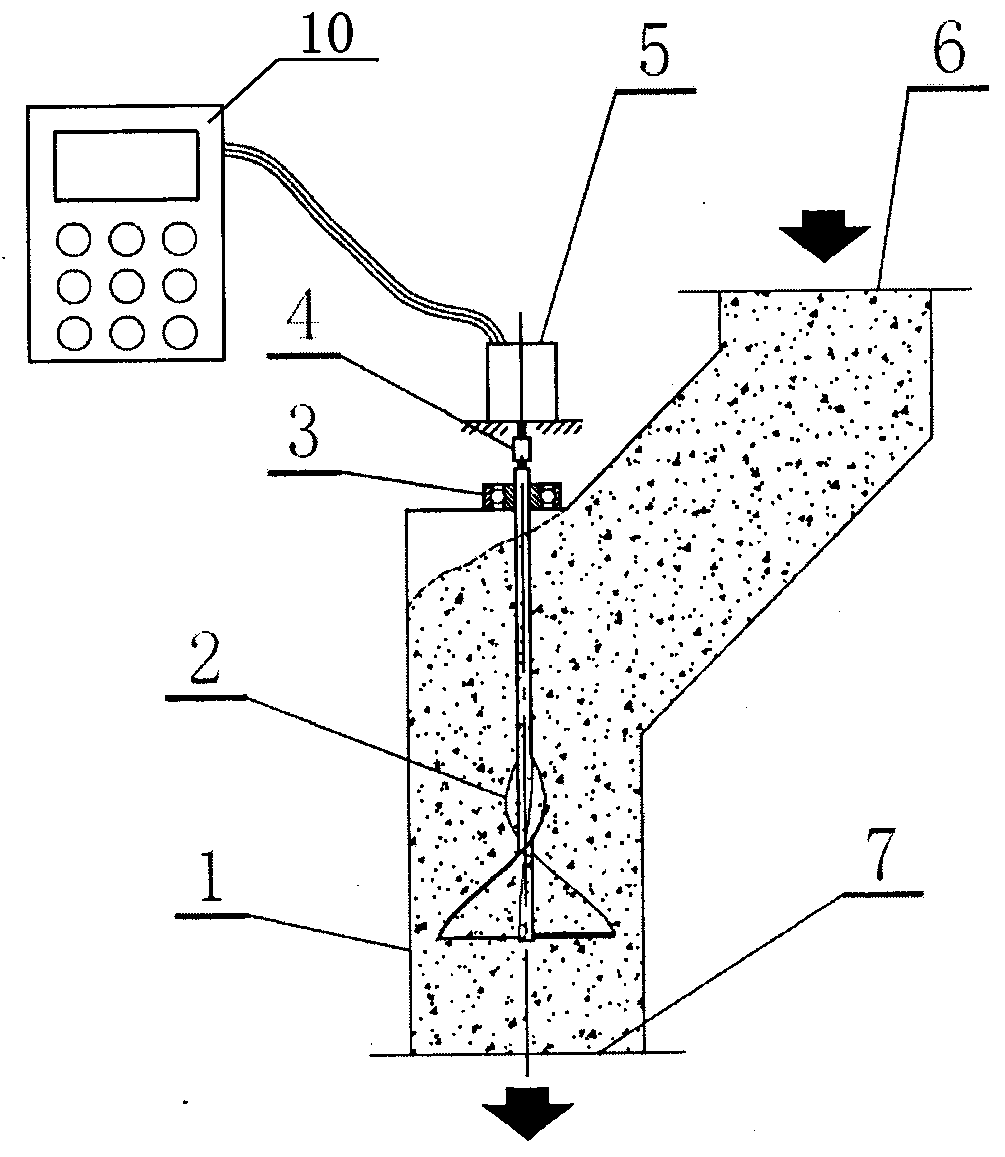

[0021] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

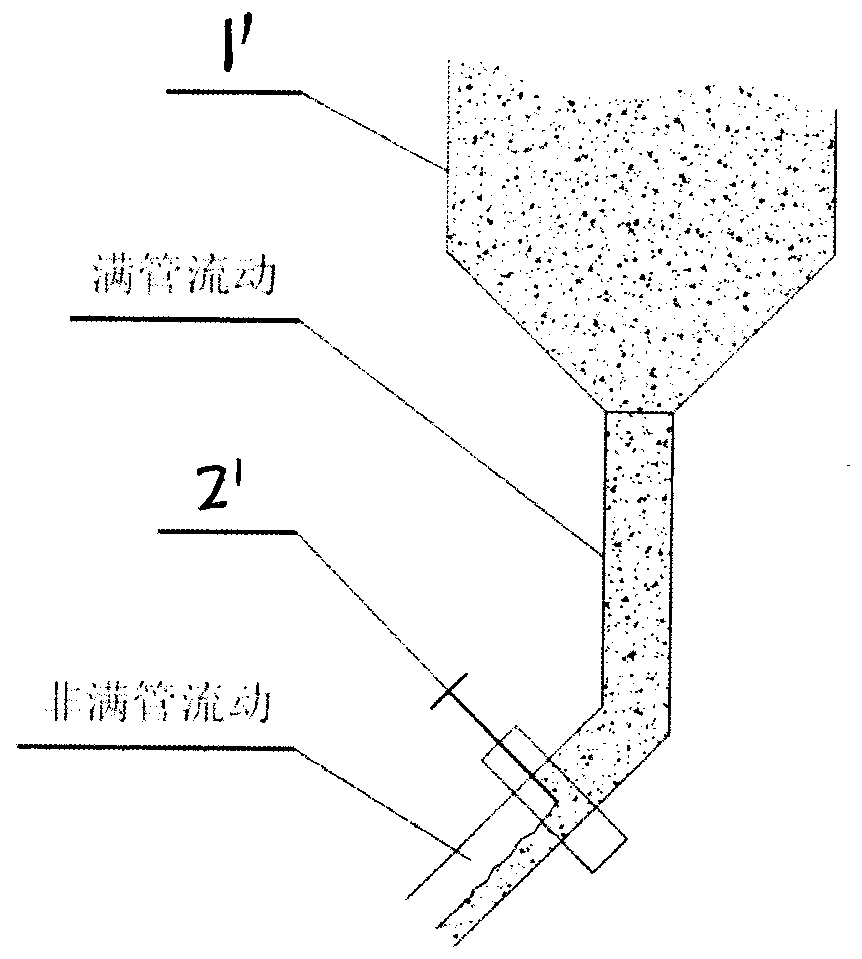

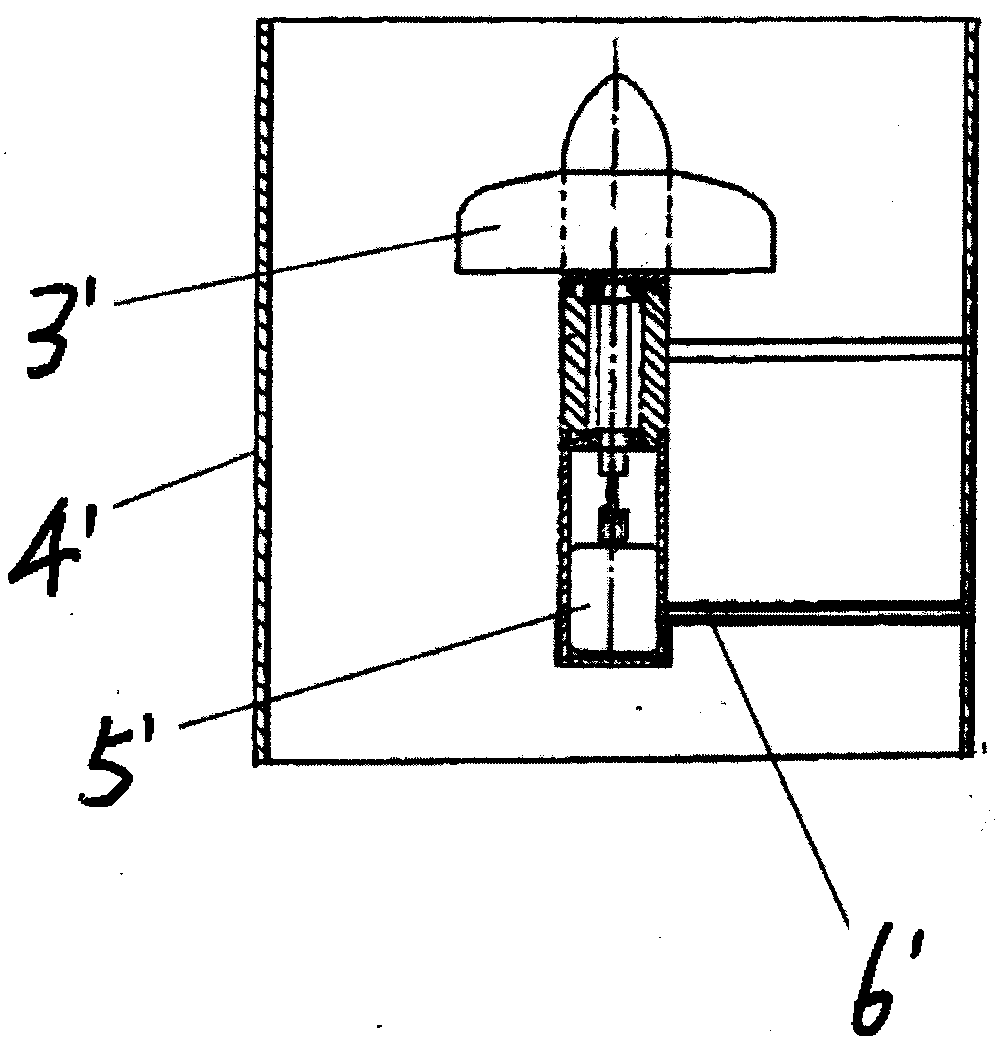

[0022] like image 3 As shown, the bulk material flow measurement device of the present invention includes a barrel 1, which is a vertically arranged cylinder with a polygonal cross-section (see Figure 5 ), the upper part of the cylinder body is provided with a feed port 6 extending to the side and connected to the discharge port of the silo, and the lower end is a discharge port 7; in the vertical cavity of the barrel 1, the The bearing 3 above the top surface of the barrel 1 is installed with a conical helix 2 in a suspended manner, and the upper end of the mandrel of the conical helix 2 is connected with the photoelectric rotary encoder 5 through a flexible coupling 4; The spiral body 2 is composed of two same equal-pitch variable-diameter helical blades 9 symmetrically welded on the mandrel 8. Each blade is wound around the mandrel for half a circle. And...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com