Overhead hoist capable of automatically stretching and retracting

A hoisting device and automatic telescopic technology, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of heavy flywheel shell, hurting people or equipment, and difficult transportation, etc., achieving good versatility and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

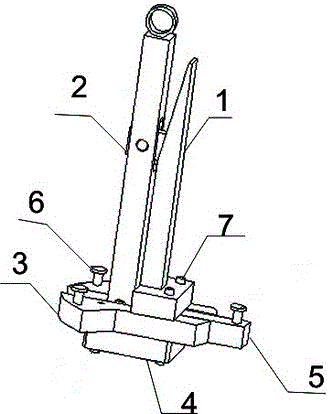

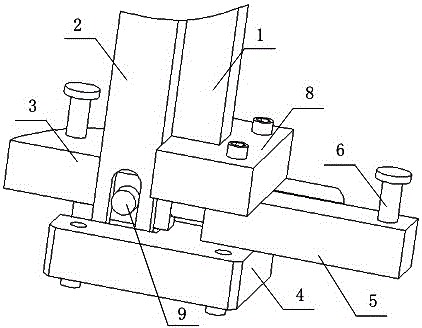

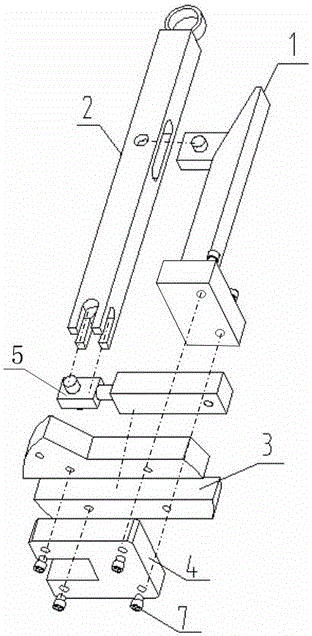

[0024] figure 1 , 2 In , 3, a support arm 1 with a hinge structure and a suspension beam 2 are installed, and the lower end of the support arm 1 is fixed on two separate base plates 3 through a support 8, and there is a fixed connection block 4 under the base plate 3; the two separate A guide groove is formed in the middle of the bottom plate 3, and the chucking head 5 can move forward and backward along the guide groove, and the moment generated by the rotation of the suspension beam 2 on the pin shaft of the support arm 1 drives the chucking head 5 to move linearly in the guide groove of the bottom plate 3 . There are two limit stop pins 6 on the left side of the bottom plate 3, and one limit stop pin 6 on the right side of the clamping head 5. There is a plastic sleeve on the limit stop pin 6 to protect the product from bumping, and the lower end of the support arm 1 is The support 8 is connected with the base plate 3 and the base plate 3 and the fixed connection block 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com