Positioning spring core support

A spring core and support piece technology, applied in the field of spring core support, can solve problems such as damage to the target part model, weak support, tilting of the core support, etc., so as to improve the yield, reduce production costs, and improve dimensional accuracy and shape and position accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

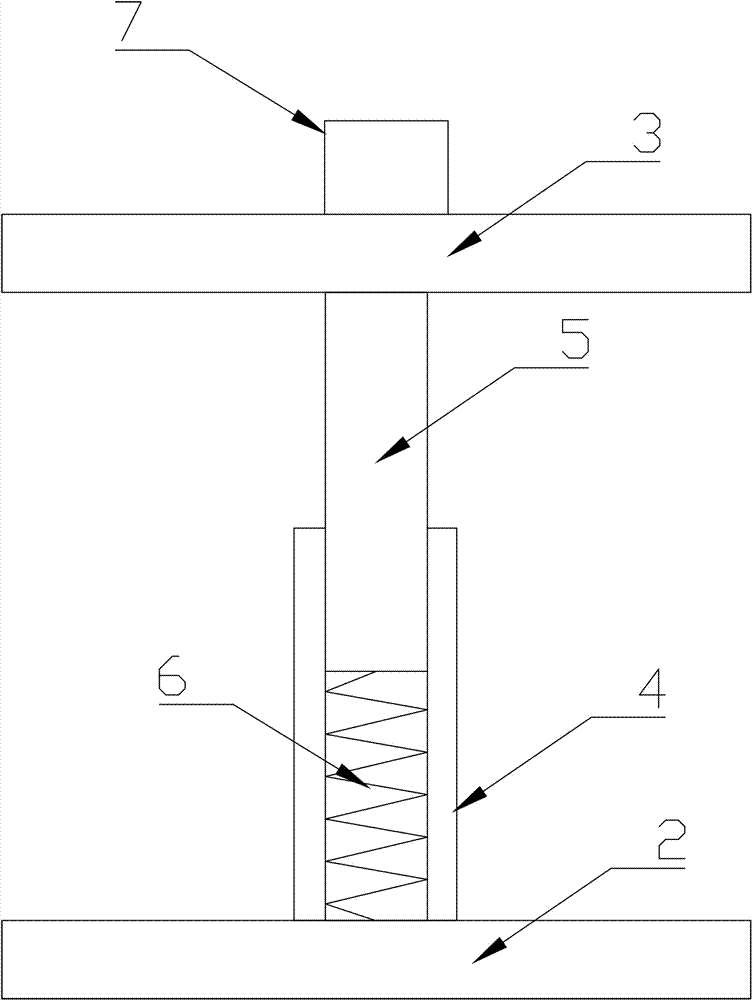

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. As shown in the figure, a spring stay includes an upper stay 3 and a lower stay 2, and a connecting piece connecting the upper stay 3 and the lower stay 2, and the materials used for the upper stay 3 and the lower stay 2 and the casting The material is the same, and its melting point is slightly higher than that of the casting metal, so as to ensure that it has enough strength to support the sand core before the casting is completely solidified, and at the same time, it is well fused with the casting during the solidification process, and the surface is clean, oil-free, and rust-free , Anhydrous, preferably galvanized or tin-plated, strictly pickling before electroplating. The connecting piece includes an upper connecting rod 5 and a lower connecting pipe 4, the lower connecting pipe 4 is a metal pipe, the upper connecting rod 5 is connected to the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com