Automatic check method and device for wheel diameter of wheel set of train

An automatic calibration and train wheel technology, which is applied in the field of rail transit vehicles, can solve the problems of difficult estimation of wheel set speed, complex implementation process, and difficult wheel diameter calibration, so as to reduce calibration costs and prevent excessive wheel diameter differences. Large, precise calibration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

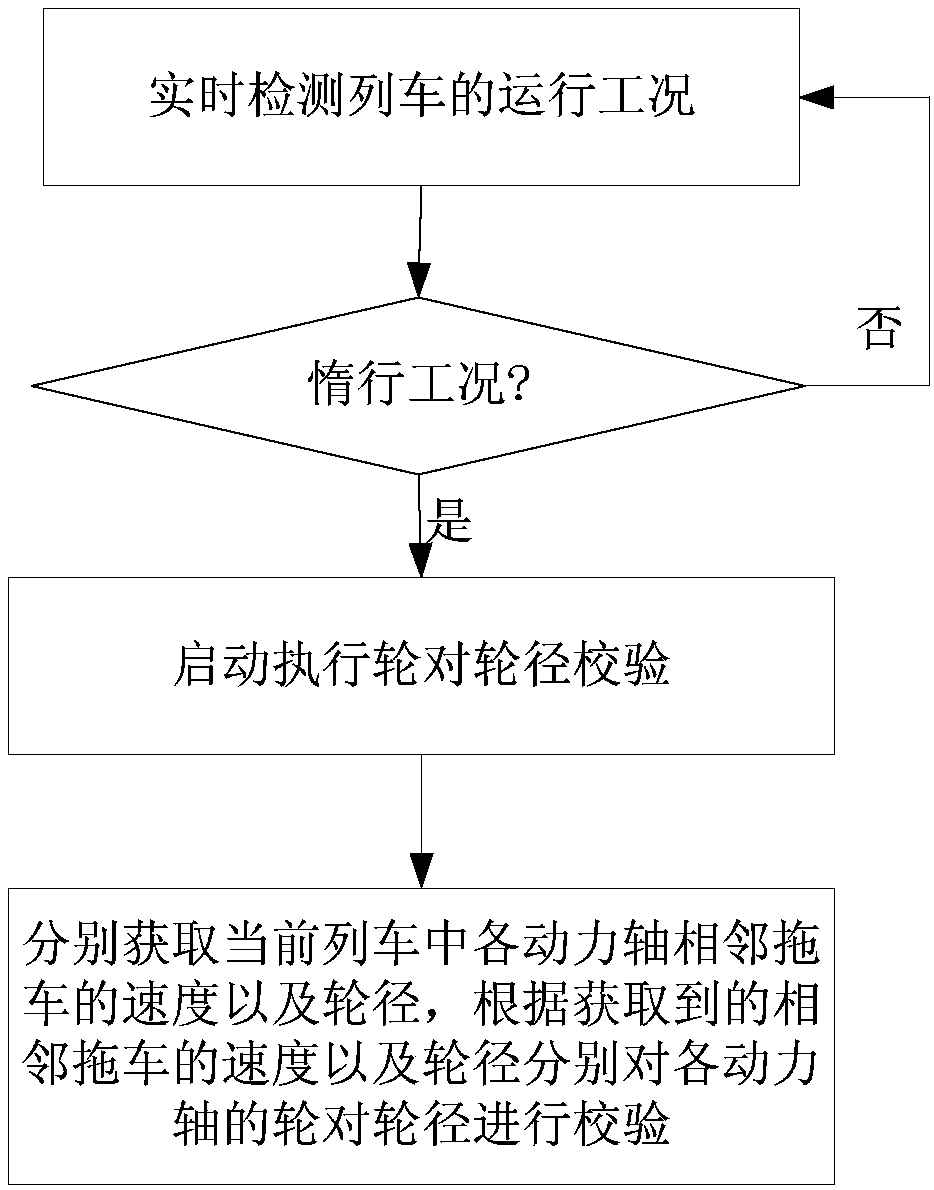

[0049] Such as figure 1 As shown, the present embodiment train wheel pair wheel diameter automatic calibration method, the steps include:

[0050] S11. Real-time detection of the operating condition of the train, when it is detected that it is in a idling condition, start to perform wheel-to-wheel diameter verification;

[0051] S12. When performing wheel-to-wheel diameter verification, respectively obtain the speed and wheel diameter of adjacent trailers of each power axle in the current train, and calculate the wheel-to-wheel diameter of each power axle according to the acquired speed and wheel diameter of adjacent trailers Verify.

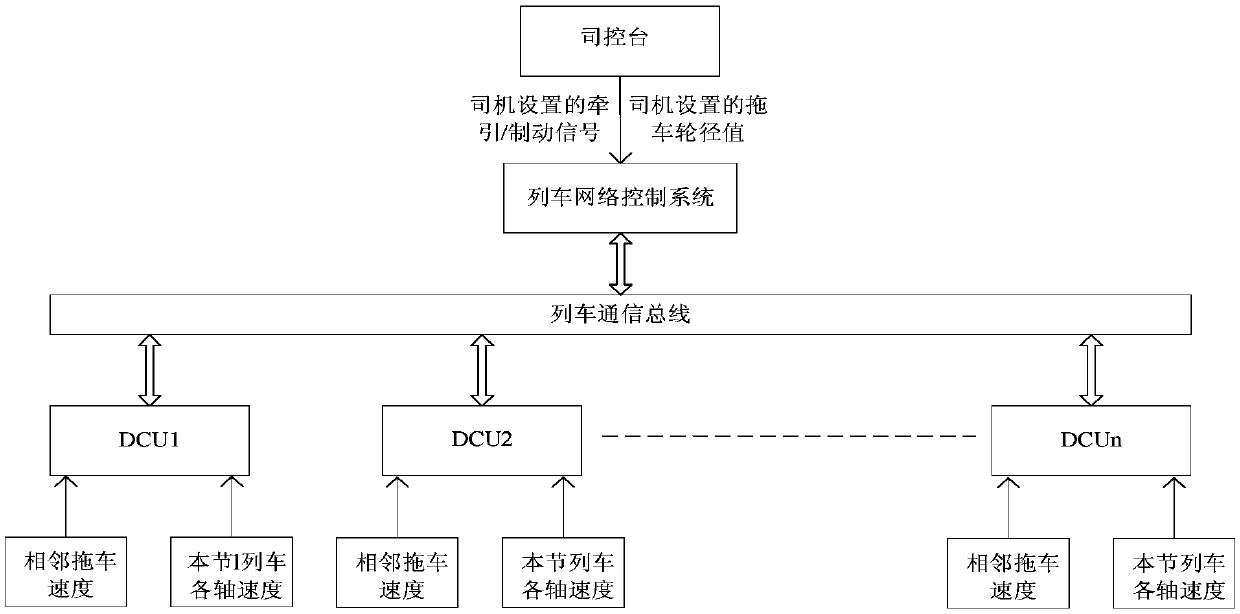

[0052] According to the relationship characteristics between the wheel-to-wheel peripheral speed and the vehicle body speed under different working conditions, the actual speed of the vehicle body is the same as the speed of the trailer when the train is in the idling condition. This embodiment specifically utilizes the relationship characteri...

Embodiment 2

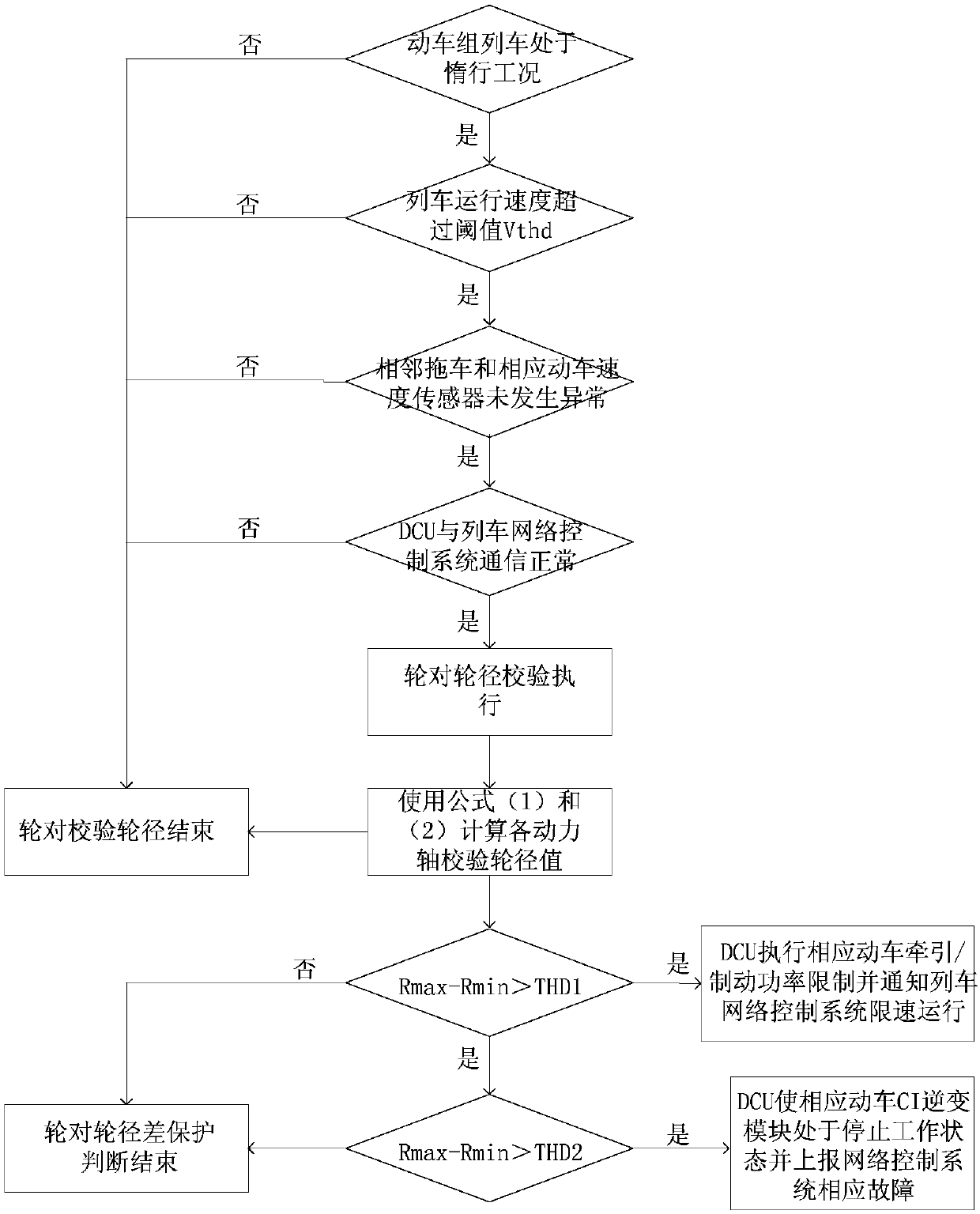

[0077] Such as Figure 5 As shown, in another embodiment of the present invention, a method for automatically verifying the wheel diameter of a train wheel, the steps include:

[0078] S21. Real-time detection of the running condition of the train, when it is detected that it is in a idling condition, start to perform wheel-to-wheel diameter verification;

[0079] S22. When performing wheel-set wheel diameter calibration, the designated power shaft is used as the calibration reference power shaft, and the speed of the calibration reference power shaft and the wheel-set wheel diameter in the current train are obtained, and according to the obtained calibration reference power The speed of the shaft and the diameter of the wheel set are verified against the wheel set diameters of other power axles in the train.

[0080] When the train is in the idling condition, the actual speed of the vehicle body is also the same as the speed of the train. This embodiment is basically the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com