A cable management tool and method for unifying network cables and management cables in the production process of rack empty cabinets

A production process and empty cabinet technology, which is applied in the field of computer communication, can solve the problem of not being able to meet the requirements of uniform length of wires, and achieve the effects of simple structure, easy processing, and improved wire management efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Configuration Tool:

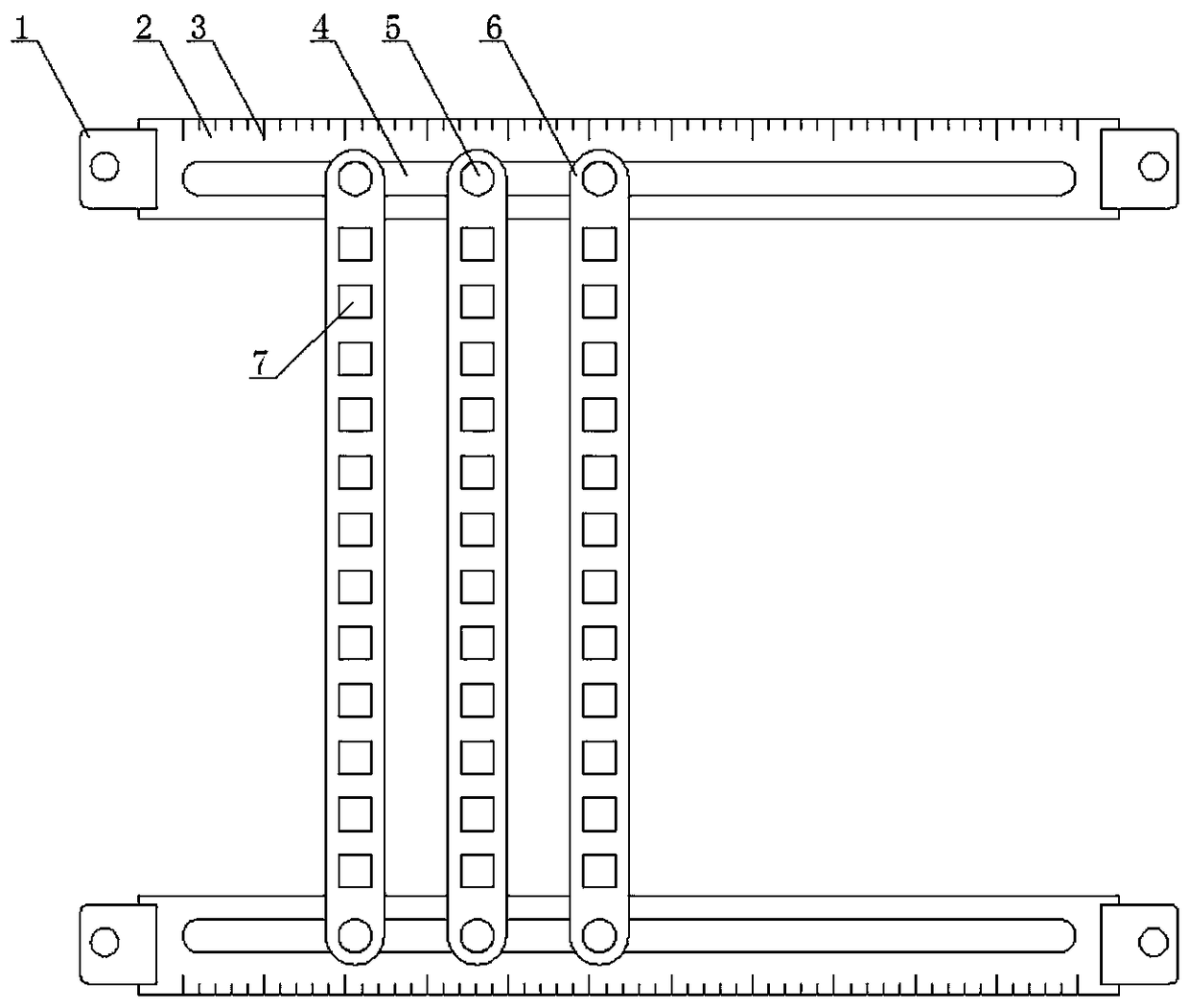

[0024] The line management tool includes two chute frames 2 parallel to each other and a positioning frame 6. The chute frames 2 are clamped on the upper and lower sides of the empty cabinet through spring screw clips 1, and the chute frames 2 are provided with sliding Slot 4, the length of the chute 4 is equal to the width of the configuration hardware surface of the empty cabinet, the surface of the chute frame 2 is equipped with a scale line 3; the two ends of the positioning frame 6 are equipped with sliding locking screws 5, The sliding locking screw 5 is slidably matched with the chute 4, and the positioning frame 6 is provided with two socket holes 7, and the socket holes 7 simulate the hardware interface on the simulation cabinet.

[0025] The steps of the line management method are as follows:

[0026] Step 1) Confirm the installation position of the pre-configured hardware interface during the production process of RACK empty cabinet acc...

Embodiment 2

[0032] Configuration Tool:

[0033] The cable management tool includes two parallel chute frames 2 and two parallel positioning frames 6, the chute frames 2 are clamped on the upper and lower sides of the empty cabinet through spring screw clips 1, the chute frames 2 There is a chute 4 on it, the length of the chute 4 is equal to the width of the configuration hardware surface of the empty cabinet, the surface of the chute frame 2 is equipped with a scale line 3; the two ends of the positioning frame 6 are equipped with sliding locks Tighten the screw 5, the sliding locking screw 5 is slidingly matched with the chute 4, and the positioning frame 6 is provided with 11 socket holes 7, and the socket holes 7 simulate the hardware interface on the simulation cabinet.

[0034] The steps of the line management method are as follows:

[0035] Step 1) Confirm the installation position of the pre-configured hardware interface during the production process of RACK empty cabinet accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com