Capsule filling machine

A filling machine and capsule technology, which is applied in the directions of capsule conveying, electromagnetic means, instruments, etc., can solve problems such as the limitation of capsule filling machines, and achieve the effect of improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

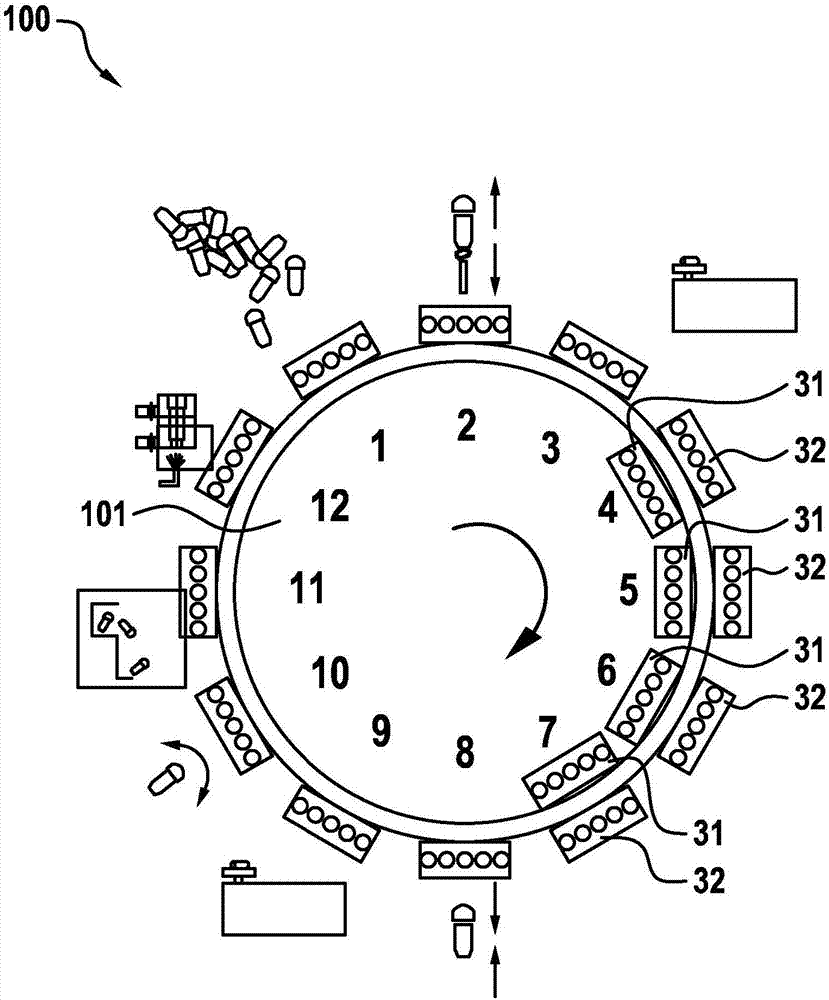

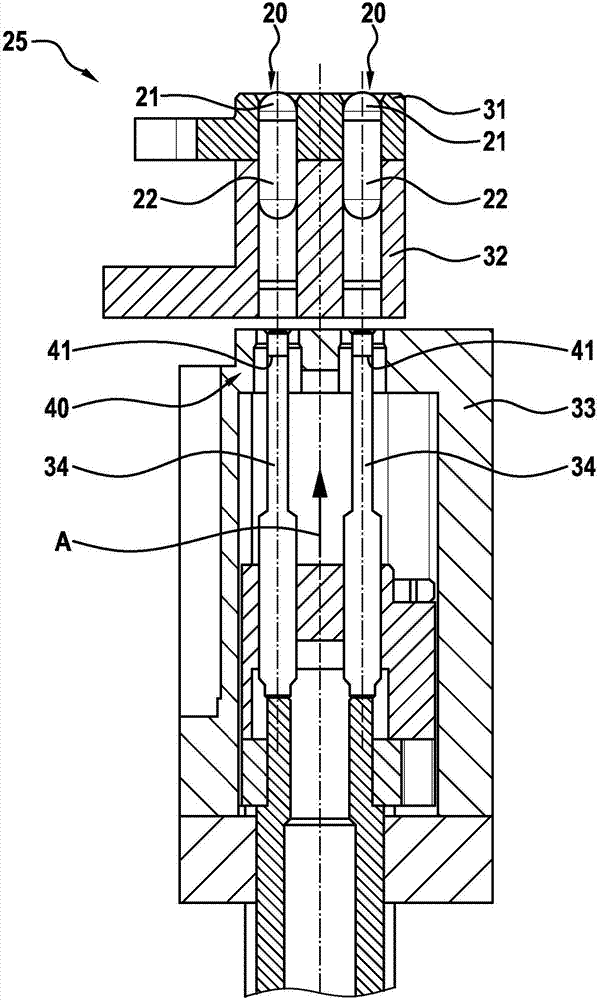

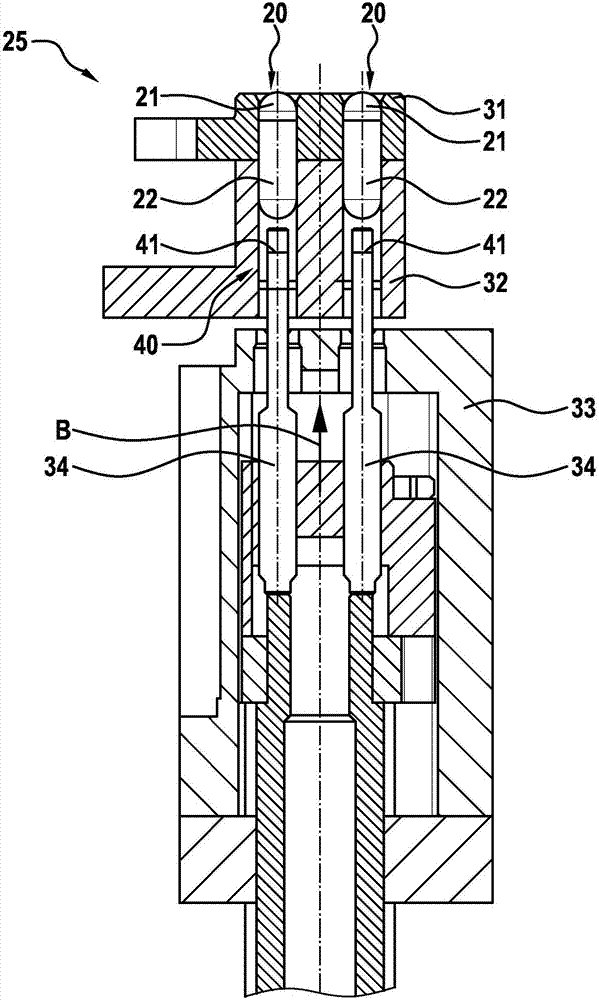

[0018] Refer below Figures 1 to 5 A capsule filling machine 1 according to a preferred embodiment of the present invention is described in detail.

[0019] as by figure 1 It can be seen that the capsule filling machine 1 comprises a rotating carousel 101 on the circumference of which twelve stations are arranged, said stations being designated by numbers 1 to 12 . Here, the capsules are fed into station 1 and separated at station 2 , wherein the capsule upper part is separated from the capsule lower part. Furthermore, in station 2 a check for the presence of capsules is carried out. as by figure 1 It can be seen that the capsule is arranged in the capsule receptacle 103, which will be described in detail later. Separation is preferably performed on a station that also supplies. However, it is also possible to carry out the separation afterwards.

[0020] Empty, unseparated capsules are weighed at station 3, and the capsule upper part is separated from the capsule lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com