Engagement/disengagement system for a friction clutch, comprising a smoothing spring

A friction clutch, smoothing technology, used in the field of return systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

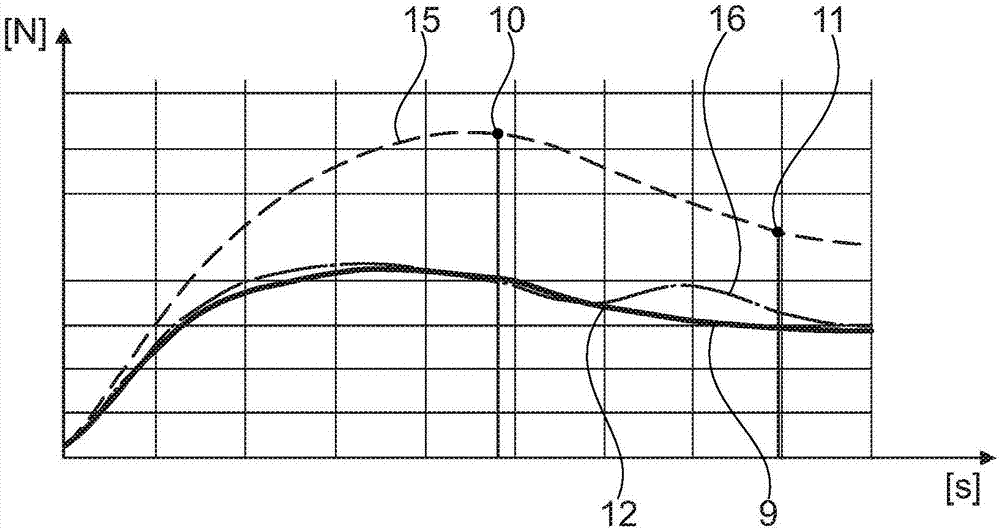

[0028] figure 1 A diagram or a Cartesian coordinate system is shown, in which the separating force in Newtons is plotted on the ordinate and the values of the restoring system 1 , not shown here, are plotted on the abscissa. Separation stroke in millimeters. A first characteristic curve 15 shown with a dashed line shows the disengagement force characteristic curve of friction clutch 2 , not shown here, without compensating spring 5 and smoothing spring 7 . A second characteristic curve 16 shown with a dotted line shows the disengagement force characteristic curve of a friction clutch 2 , not shown here, with compensating spring 5 but without smoothing spring 7 . It can be seen here that the second characteristic curve 16 has a “bump” between the operating point 10 and the disengagement point 11 of the restoring system 1 , not shown here, which is negatively affected by the user of the restoring system 1 . aware. The characteristic curve 9 shows the disengagement force cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com