Foam clamping equipment

A foam and equipment technology, which is applied in the field of foam clamping equipment, can solve the problems of foam deformation, damage to the overall appearance of the workpiece, easy to produce deviation, etc., and achieve the effect of high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

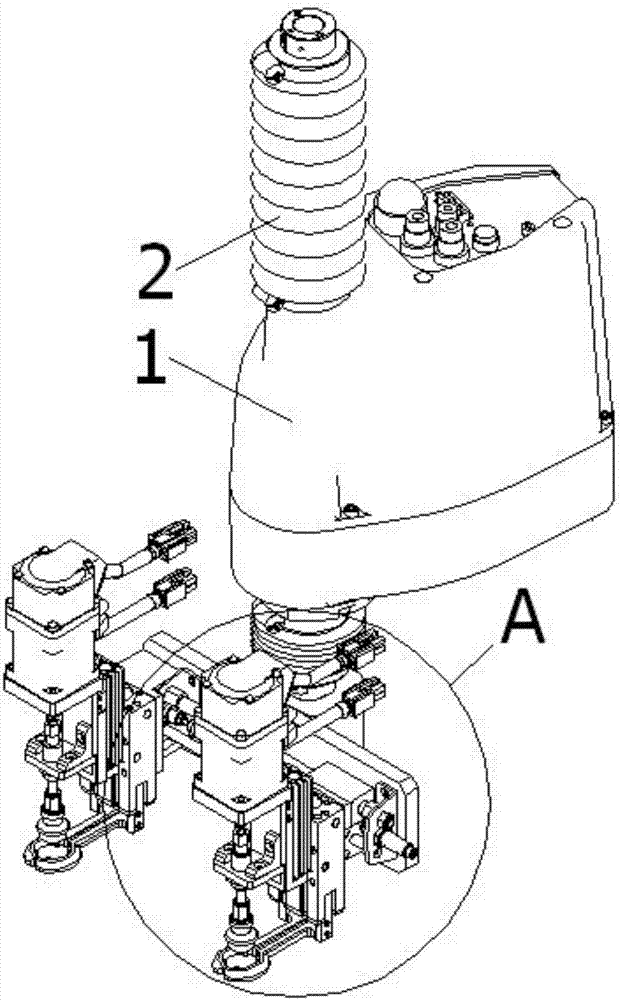

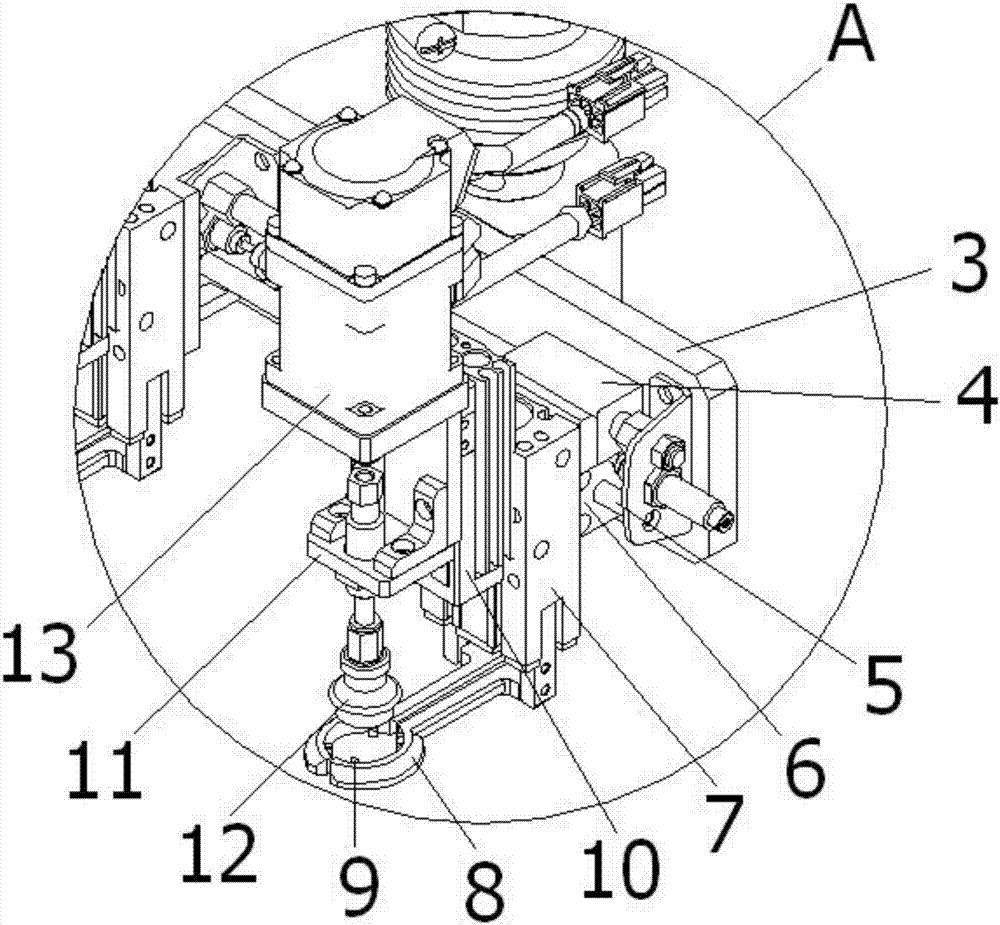

[0014] attached Figure 1-2 It is the clamping foam equipment according to the present invention; it includes a mechanical arm 1; the front part of the mechanical arm 1 is provided with a rotating shaft 2; the lower part of the rotating shaft 2 is provided with a movable frame 3; the movable frame 3 can rotate around the rotating shaft 2 The front end of the movable frame 3 is provided with a rodless assembly 4 and a slide bar 5; the slide bar 5 is provided with a slider 6, and the slide block 6 is connected with the rodless assembly 4; the rodless assembly 4 is driven by a cylinder The slider 6 can be translated left and right; the front end of the slider 6 is provided with a vertical jaw cylinder 7; the jaw cylinder 7 is provided with a jaw 8, and the inner wall of the jaw 8 is provided with a plurality of protrusions 9. The jaw cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com