Engine controller

A control device and engine technology, applied in the direction of engine control, combustion engine, machine/engine, etc., can solve problems such as pressure boost limitation, inability to fully experience the vehicle's operating feeling, acceleration not following accelerator pedal pedaling amount or pedaling speed, etc. , to achieve the effect of improving acceleration responsiveness and ensuring emission suppression performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

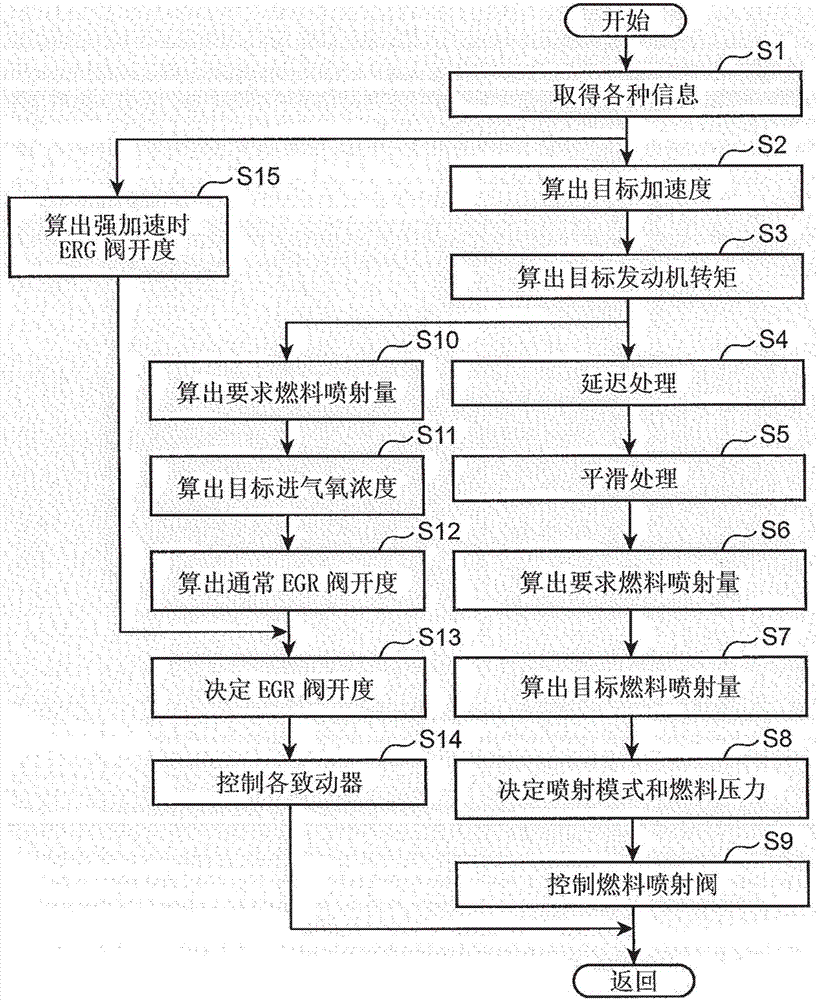

[0021] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0022]

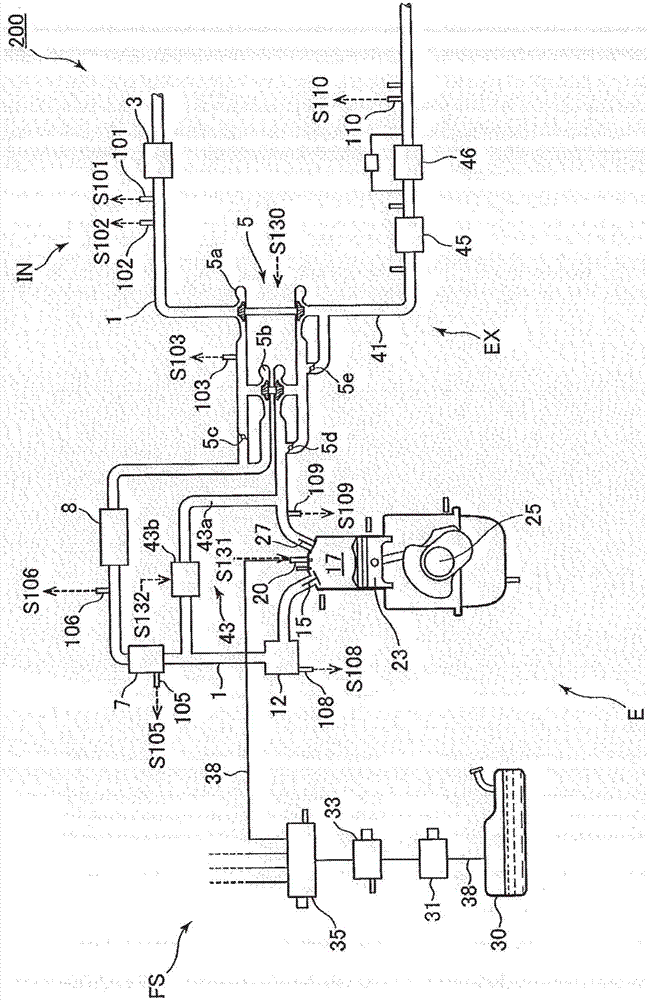

[0023] First, according to figure 1 An engine system to which the engine control device according to the embodiment of the present invention is applied will be described.

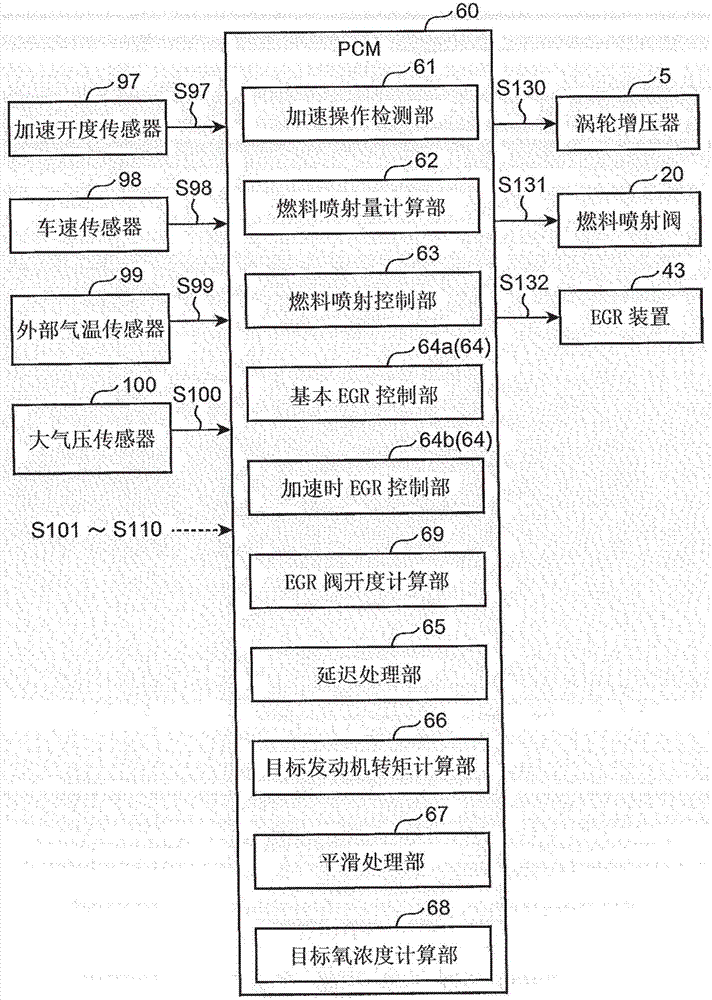

[0024] Such as figure 1 As shown, the engine system 200 includes: a diesel engine E (hereinafter referred to as the engine E); an intake system IN for supplying intake air to the engine E; a fuel supply system FS for supplying fuel to the engine E; exhaust gas discharged from the engine E exhaust system EX; sensors 97 to 110 that detect various states related to the engine system 200; PCM (Power train Control Module) 60 that performs control of the engine system 200 (such as figure 2 shown).

[0025] The intake system IN has an intake channel 1 through which intake air passes. On the intake passage 1, an air cleaner 3 that cleans the air introduced fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com