Compact ultrasound transducer with direct coax attachment

一种同轴电缆、换能器的技术,应用在制造其领域,能够解决空间利用率低、制造复杂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

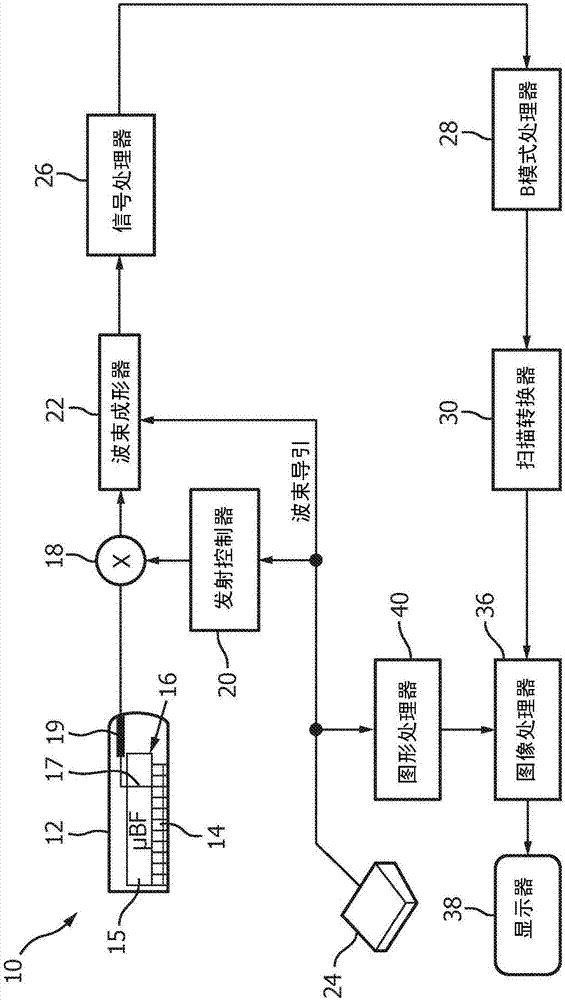

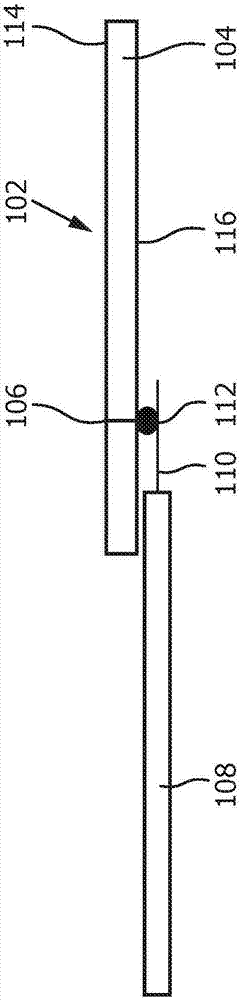

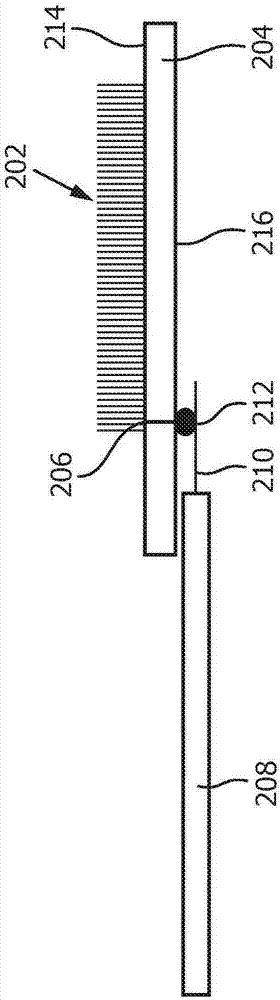

[0020] In accordance with the principles of the present invention there is provided an ultrasonic transducer, transducer assembly and method for manufacture. The principles of the present invention provide an array of transducers on a substrate in which vias, especially through silicon vias (TSVs), can be employed. The vias are formed through the substrate on which the transducer elements are formed or mounted. The vias can then be connected by a coaxial cable. In this way, an easily manufacturable design is provided, with more compact dimensions, more efficient use of space, and thus a significant reduction in costs.

[0021] In one embodiment, a capacitive micromachined ultrasound transducer (CMUT) is employed. CMUT substrates provide a smaller form factor and are useful for compact designs. Additionally, the CMUT substrate allows for the formation of vias to connect coaxial cables to the transducer elements. In another embodiment, a one-dimensional array of transducer e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com