A sludge flow tester

A tester and silt technology, applied in the field of silt flow tester, can solve the problems of limited growth of soil strength, little guiding significance, silting of plastic drainage boards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A specific embodiment of the present invention is given below, and the present invention will be further described in detail through this embodiment. It is necessary to point out that the implementation case is only used to further illustrate the present invention, and the protection scope of the present invention is not limited to this. Some non-essential adjustments and improvements made to the present invention by those skilled in the art still belong to the protection scope of the present invention.

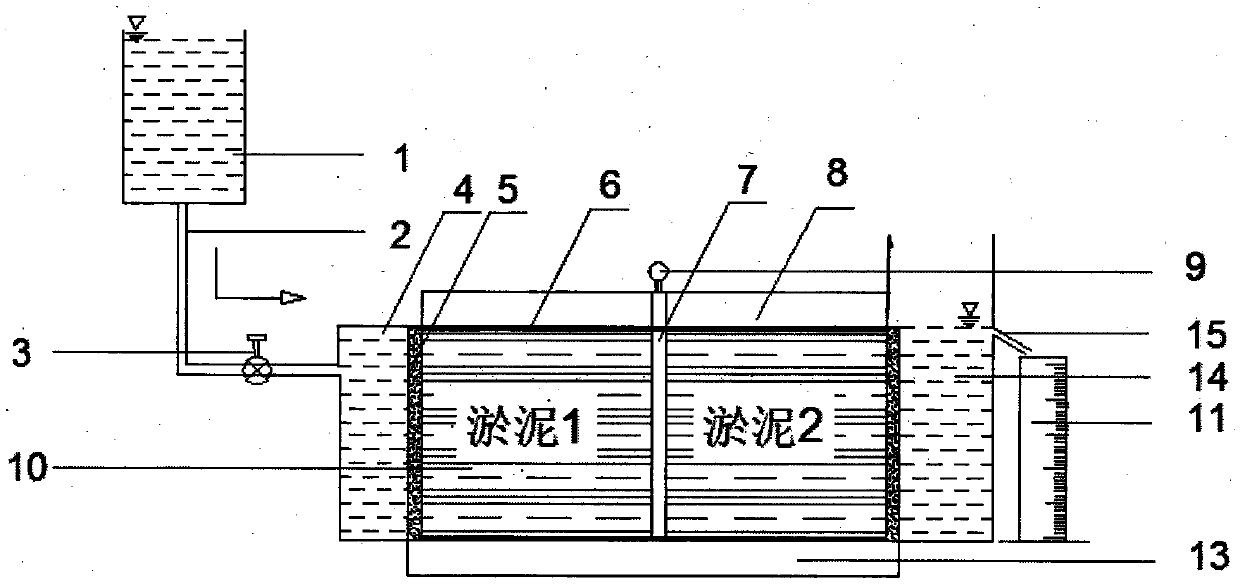

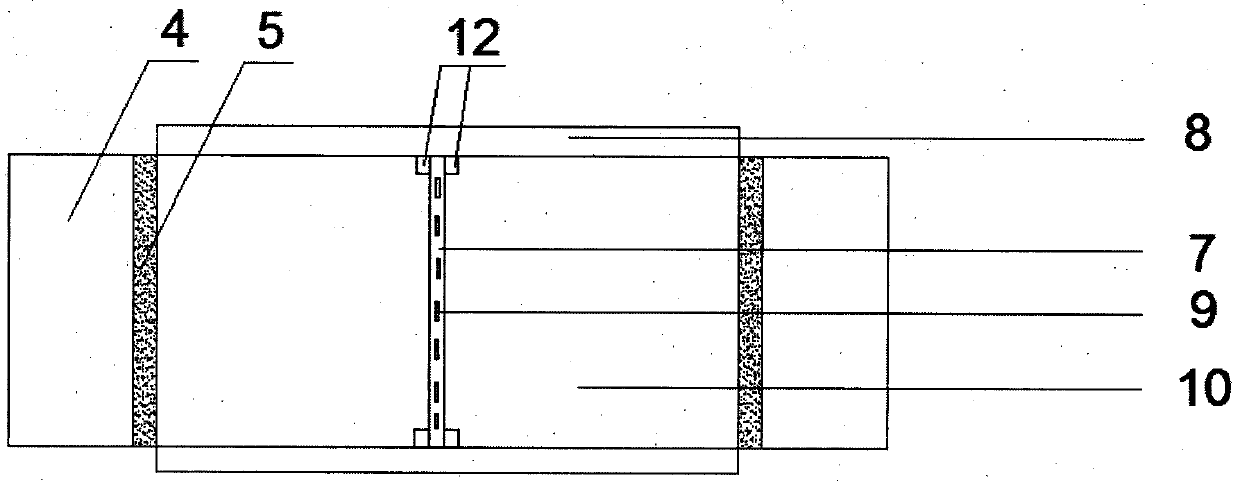

[0019] See Figure 1-2 , A sludge flow tester, comprising a pressure head container 1, the pressure head container 1 and the left water reservoir 4 are connected and sealed by a connecting pipe 2, a water stop valve 3 adjustment switch is provided on the connecting pipe 2, and the left water reservoir 4 There is a permeable stone 5 of a suitable size between the sample chamber 10 and the upper and lower ends of the sample chamber. An upper fixing box 8 and a lower fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com