Welding device

A welding device and communication technology, which is applied to the parts, coupling devices, connections, etc. of the connecting device, can solve the problems of easy arcing, hidden dangers, power supply interruption, etc., to avoid electric shock accidents, high safety, and easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

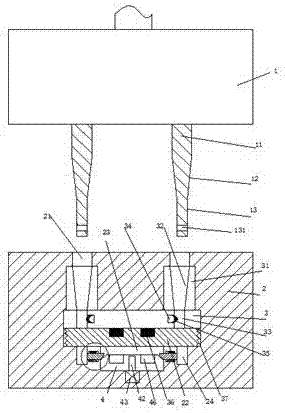

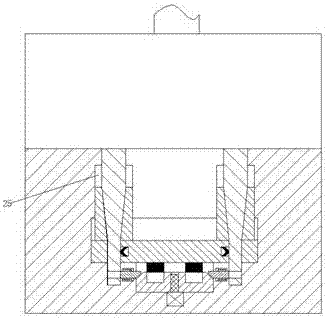

[0020] Combine below Figure 1-5 The present invention will be described in detail.

[0021] refer to Figure 1-5 , a welding device according to an embodiment of the present invention, including a power distribution base 2 and a power plug 1 arranged in the top of a distribution box 100, including a power plug 1 and a power distribution base 2, the power plug 1 The lower end is fixed with an insertion rod 11, the lower end of the insertion rod 11 is provided with a tapered portion 12 and a pointed needle portion 13 located at the lower end of the tapered portion 12, and the pointed needle portion 13 is provided with a lock hole 131 extending left and right , the top of the power distribution box 100 is located above the power distribution base 2 and is reversibly provided with an end cover 101. The end cover 101 is used to cover the power distribution base 2 when it is not plugged in, so as to prevent dust The power distribution seat is provided with a sliding cavity 22, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com