Inverter DC module

A DC module and inverter technology, which is applied in the direction of converting AC power input to DC power output, converting irreversible DC power input into AC power output, and converting equipment structural parts, etc. Increased difficulty in installation and maintenance of transformer DC circuit breakers, inconvenient installation of spare parts, streamlined production, modular production, and reduced benefits, to achieve the effects of convenient streamlined production, simple installation methods, and improved installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below in conjunction with accompanying drawing:

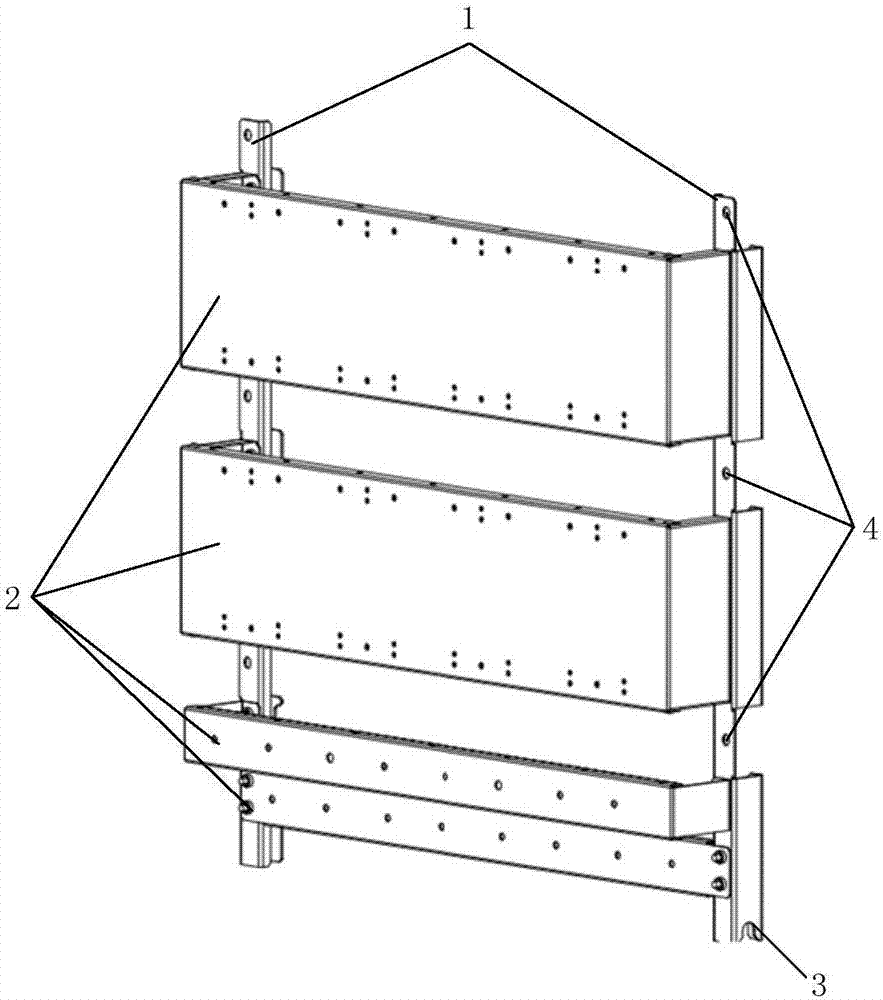

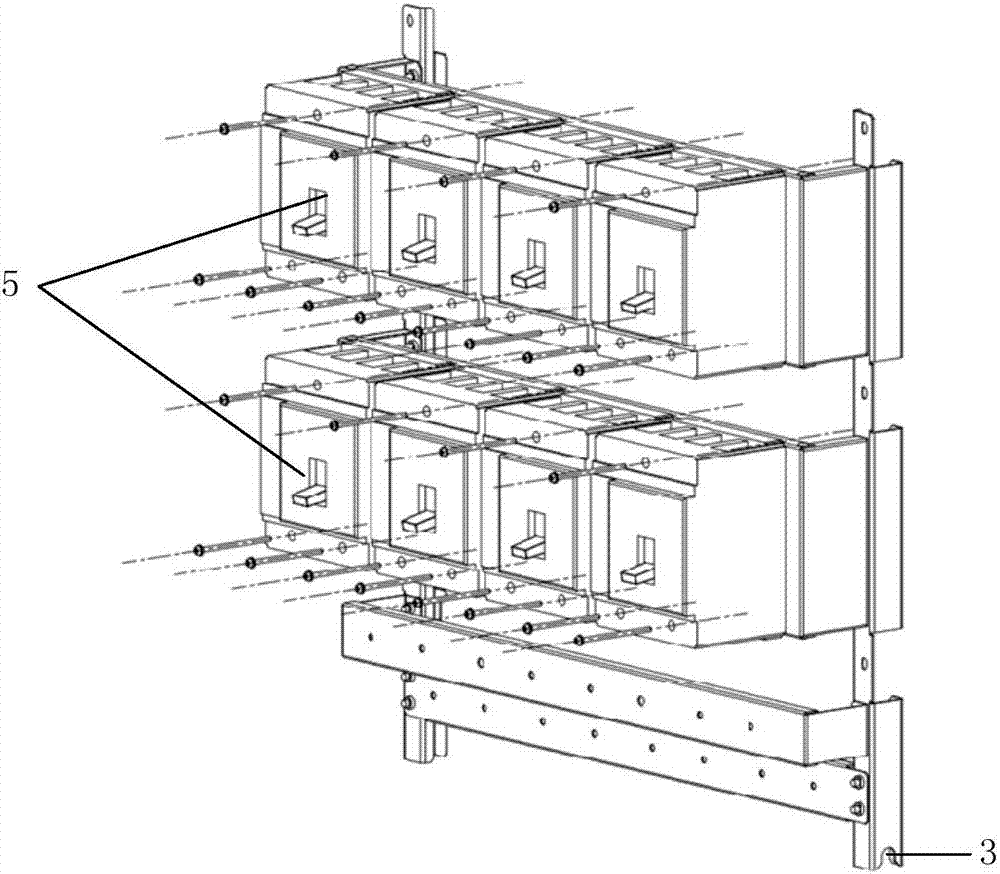

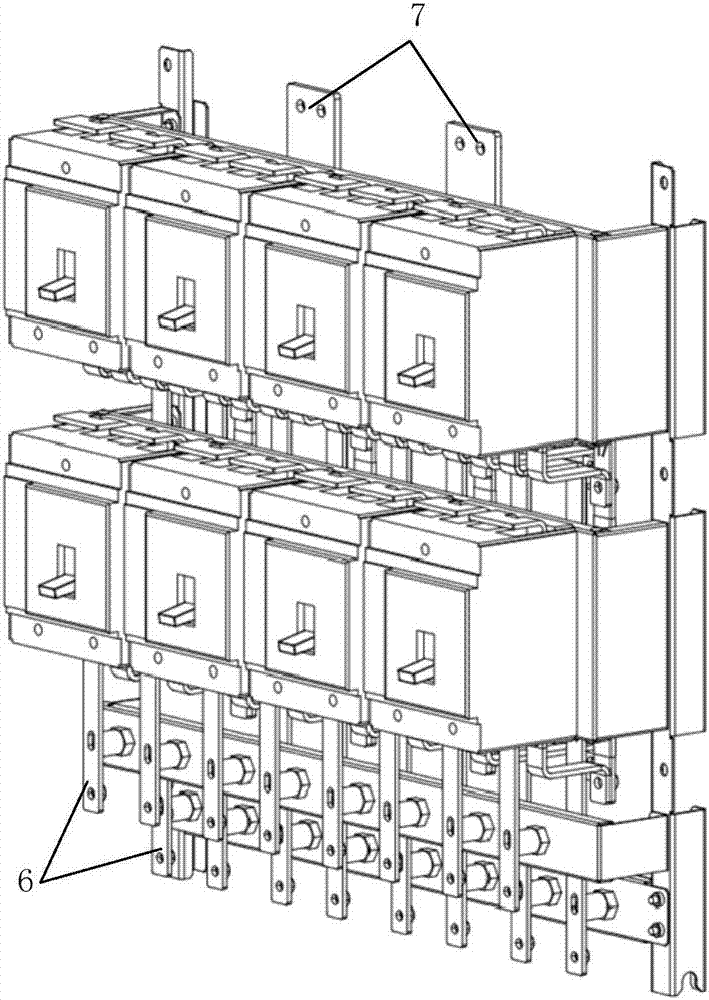

[0022] Such as figure 1 As shown, it consists of two vertical sheet metal beams 1, two upper sheet metal panels 2-1 and two lower sheet metal panels 2-2 installed laterally on the two vertical sheet metal beams 1 A trapezoidal mounting bracket, the two upper sheet metal panels 2-1 are used to install the DC circuit breaker, and the two lower sheet metal panels 2-2 are used to install the connection input copper bars of the circuit breaker; the trapezoidal installation There is a notch 3 at the bottom of the vertical sheet metal crossbeam 1 on both sides of the bracket, and the notch 3 is a notch overlapped with the step screw 8 on the cabinet when the DC module is installed on the cabinet. The upper, middle and lower positions of the two vertical beams are all provided with fixing holes 4, which are used for fixing holes for screws when fixing to the cabinet.

[0023...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com