Sensing type automatic material collecting counter

An automatic material receiving and sensing technology, which is applied to the detailed information of instruments, weighing equipment, measuring devices, etc., can solve the problems of counterfeit labels, error-prone vehicle drivers, two-way loss of material yards and receiving points, etc. Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

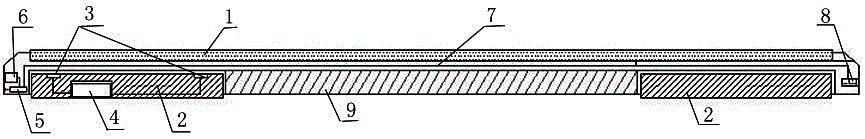

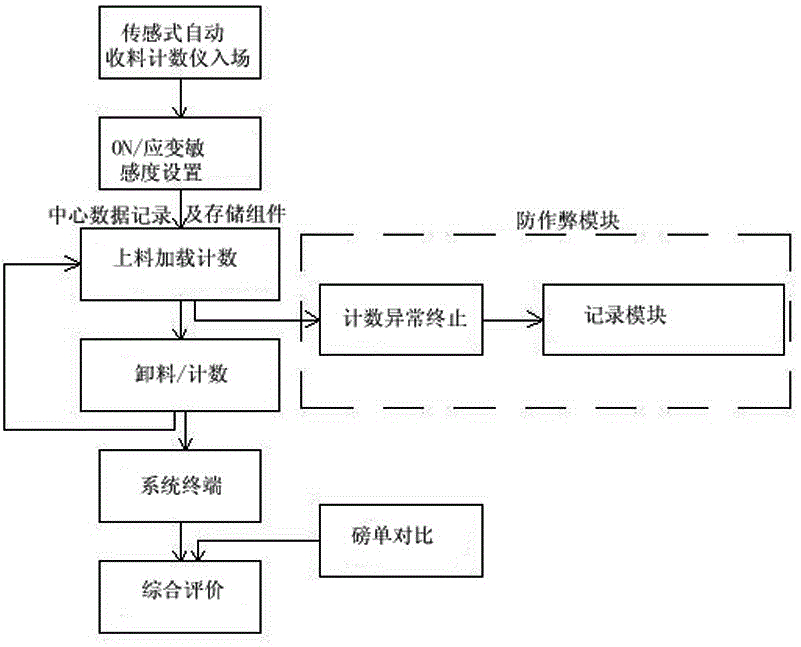

[0021] The present invention as figure 1 , 2 shown.

[0022] The sensor-type automatic receiving counter includes a pressure sensor 1, a pressure reed 2 is provided under the pressure sensor 1 through a signal transmission line 7, an elastic contact 3 is arranged on the pressure reed 2, and the elastic contact 3 is under the pressure sensor 1 to form a point contact, and the elastic contact 3 is connected to the power supply 4 through a wire;

[0023] The signal conduction line 7 is connected with the central data recording and storage 5, and the corresponding central data recording and storage component 5 is provided with a clearing device and a USB interface 6;

[0024] The central data recording and storage component 5 also forms a connection relationship with the system terminal through wireless transmission.

[0025] The central data recording and storage component 5 is also provided with an anti-cheating module, wherein the anti-cheating module includes a counting abn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com