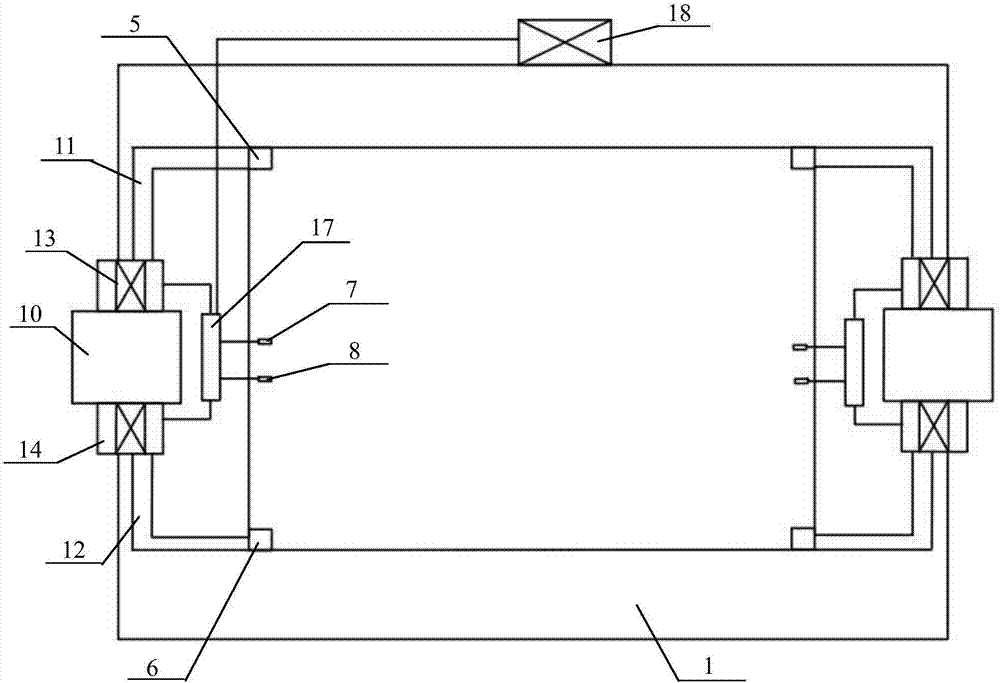

Intelligent automatic noise reduction and fireproofing hollow glass window, building and method of intelligent automatic noise reduction and fireproof hollow glass window

A glass window and hollow technology, which is applied in building structures, buildings, fire doors, etc., can solve the problems of general sound insulation effect, inability to play a fireproof function, and increased load-bearing of the window frame, and achieve good noise reduction or fireproof effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

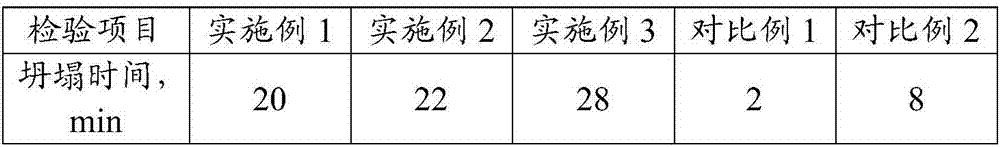

Embodiment 1

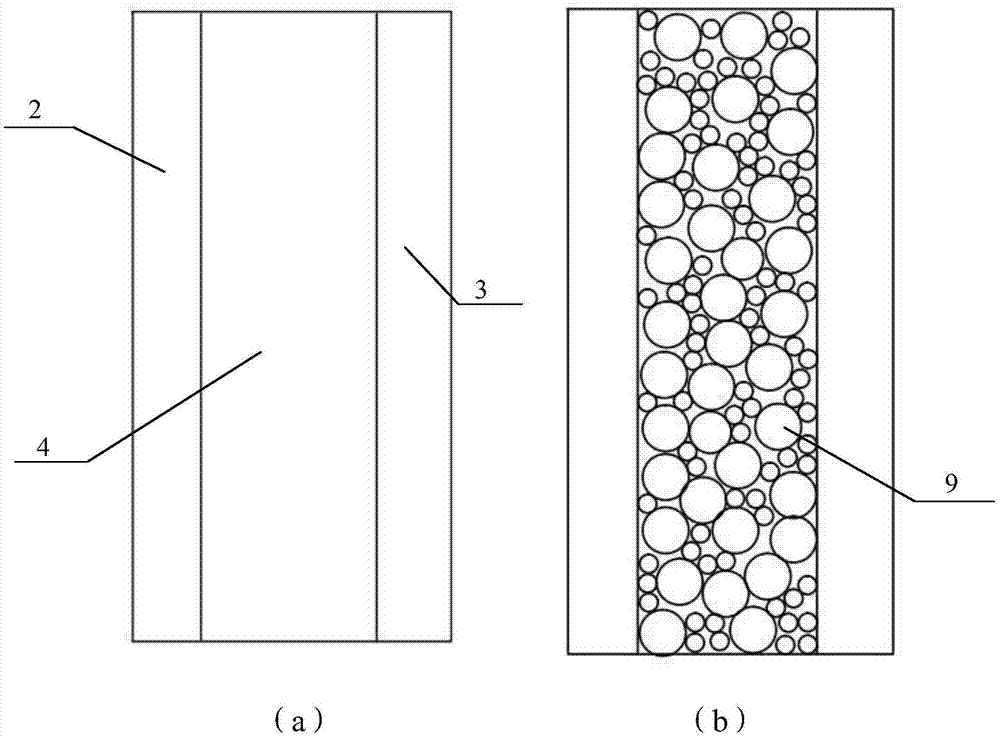

[0052] The mixing ratio of hollow plastic balls and hollow glass balls in sound insulation and fireproof materials is 7:3, the outer diameter of the hollow glass balls is 0.5mm, the inner diameter is 0.25mm, the outer diameter of the hollow plastic balls is 5mm, the inner diameter is 2.5mm, and the hollow The thickness of the interlayer is 12mm. At this time, the hollow plastic ball is made of polyacrylamide, and the hollow glass ball is made of high borosilicate glass.

Embodiment 2

[0054] The mixing ratio of hollow plastic balls and hollow glass balls in sound insulation and fireproof materials is 1:1, the outer diameter of the hollow glass balls is 1mm, the inner diameter is 0.5mm, the outer diameter of the hollow plastic balls is 5mm, the inner diameter is 3.75mm, and the hollow interlayer The thickness of the hollow plastic ball is 12mm. At this time, the material of the hollow plastic ball is polyacrylamide, and the material of the hollow glass ball is high borosilicate glass.

Embodiment 3

[0056] The mixing ratio of hollow plastic balls and hollow glass balls in sound insulation and fireproof materials is 3:2, the outer diameter of the hollow glass balls is 0.8mm, the inner diameter is 0.5mm, the outer diameter of the hollow plastic balls is 5mm, the inner diameter is 3mm, and the hollow interlayer The thickness of the hollow plastic ball is 12mm. At this time, the material of the hollow plastic ball is polyacrylamide, and the material of the hollow glass ball is high borosilicate glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com