Thermoplastic colorless and transparent glass protection ink and preparation method thereof

A technology for protecting ink and transparent glass, applied in ink, household appliances, applications, etc., can solve the problems of affecting light transmittance, easy yellowing of colorless and transparent ink, easy to scratch and resistant to CNC process, etc., and achieve alkali fading time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of resin semi-finished products

[0041]Thermoplastic acrylic resin 50 parts

[0042] 20 parts of diethylene glycol monoethyl ether acetate (boiling point 217°C)

[0043] 30 parts of diethylene glycol monobutyl ether acetate (boiling point 246°C)

[0044] Among them, the thermoplastic acrylic resin is colorless and transparent particles, with a weight average molecular weight of 18500, an acid value of 205 mg KOH / g, a solid content of >99.8%, a tg point of 128°C, and a softening point of 172°C;

[0045] Just disperse and dissolve through a stirring disperser;

[0046] (2) Preparation of protective ink

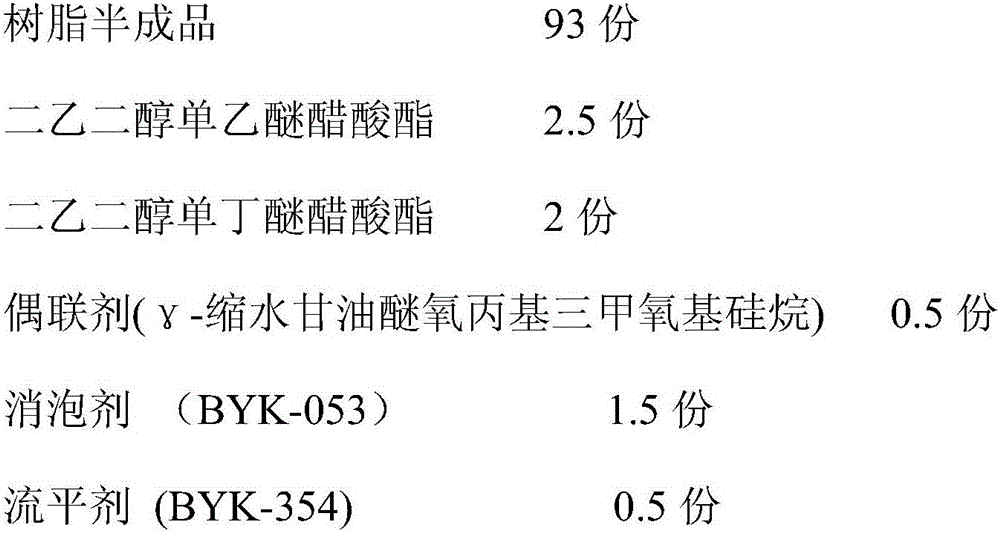

[0047]

[0048] Stir and disperse with a stirring disperser for about 20 minutes, and wait for the ink to disperse evenly;

[0049] The performance test result of printing ink that present embodiment makes is as follows:

[0050] Viscosity: 200~250dpa·s25℃

[0051] Adhesion 5B

[0052] Hardness 4H~7H

[0053] Resistance to cutting fluid polishi...

Embodiment 2

[0057] (1) Preparation of resin semi-finished products

[0058] Thermoplastic acrylic resin 70 parts

[0059] 30 parts of methyl nylon acid (boiling point 195°C)

[0060] Among them, the thermoplastic acrylic resin is colorless and transparent particles, with a weight average molecular weight of 10500, an acid value of 100 mg·KOH / g, a solid content of >99.8%, a tg point of 117°C, and a softening point of 160°C;

[0061] Just disperse and dissolve through a stirring disperser;

[0062] (2) Preparation of protective ink

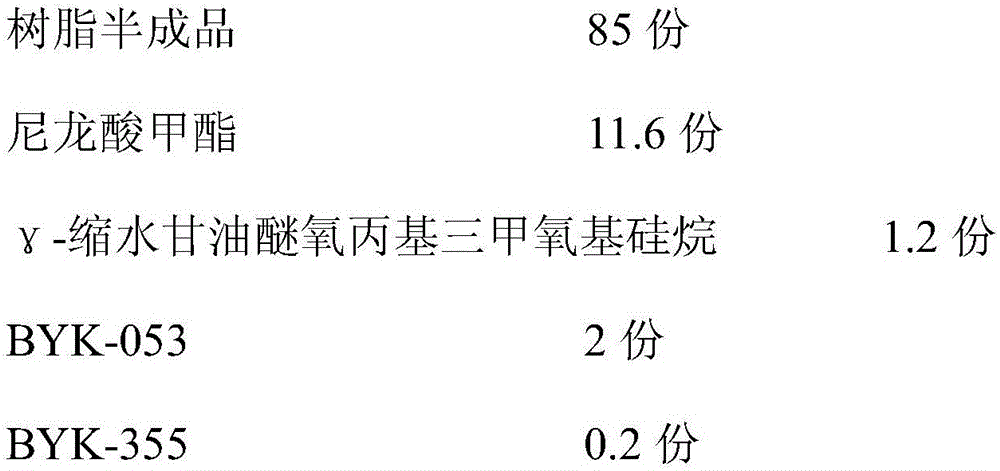

[0063]

[0064] Stir and disperse with a stirring disperser for about 20 minutes, and wait for the ink to disperse evenly;

[0065] The performance test result of printing ink that present embodiment makes is as follows:

[0066] Viscosity: 200~250dpa·s25℃

[0067] Adhesion 5B

[0068] Hardness 4H~7H

[0069] Resistance to cutting fluid polishing fluid > 2h

[0070] Water resistance>2h

[0071] Alkali fade time <60s40℃.

Embodiment 3

[0073] (1) Preparation of resin semi-finished products

[0074] Thermoplastic acrylic resin 50 parts

[0075] 20 parts of diethylene glycol monoethyl ether acetate

[0076] 30 parts of diethylene glycol monobutyl ether acetate

[0077] Among them, the thermoplastic acrylic resin is colorless and transparent particles, with a weight average molecular weight of 30,000, an acid value of 185 mg·KOH / g, a solid content of >99.8%, a tg point of 78°C, and a softening point of 140°C;

[0078] Just disperse and dissolve through a stirring disperser;

[0079] (2) Preparation of protective ink

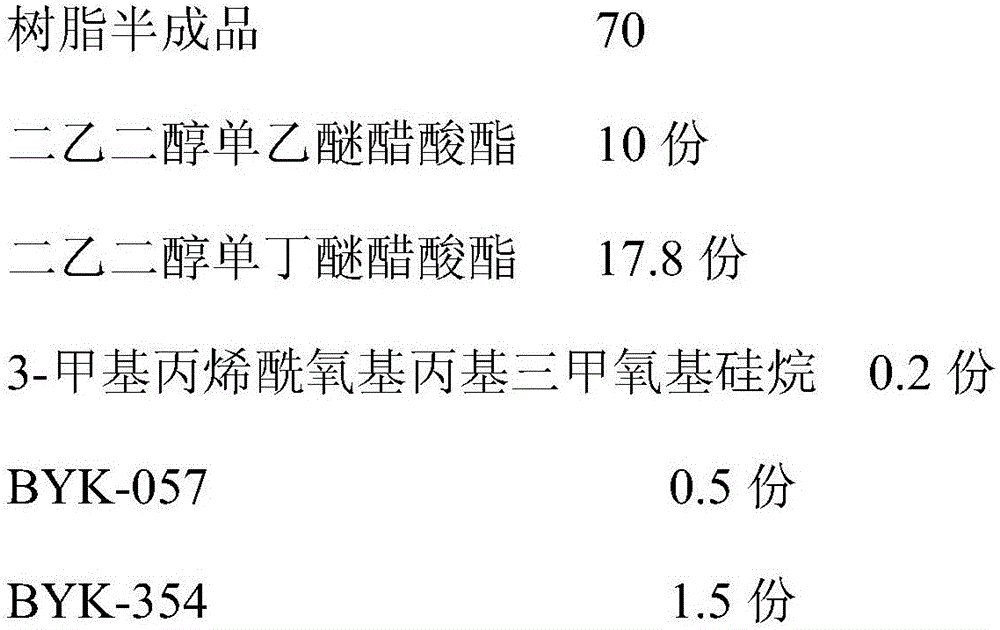

[0080]

[0081] Stir and disperse with a stirring disperser for about 30 minutes, and wait for the ink to disperse evenly;

[0082] The performance test result of printing ink that present embodiment makes is as follows:

[0083] Viscosity: 200~250dpa·s25℃

[0084] Adhesion 5B

[0085] Hardness 4H~7H

[0086] Resistance to cutting fluid polishing fluid > 2h

[0087] Water resistance>2h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com