Array substrate and manufacturing method thereof, and display device

An array substrate and manufacturing method technology, applied in the field of display, can solve the problems affecting the uniformity and stability of the common electrode network voltage, affecting the actual voltage difference of liquid crystal, and the crosstalk of the common electrode network voltage, so as to improve the display quality and coupling capacitance The effect of reducing and uniform voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

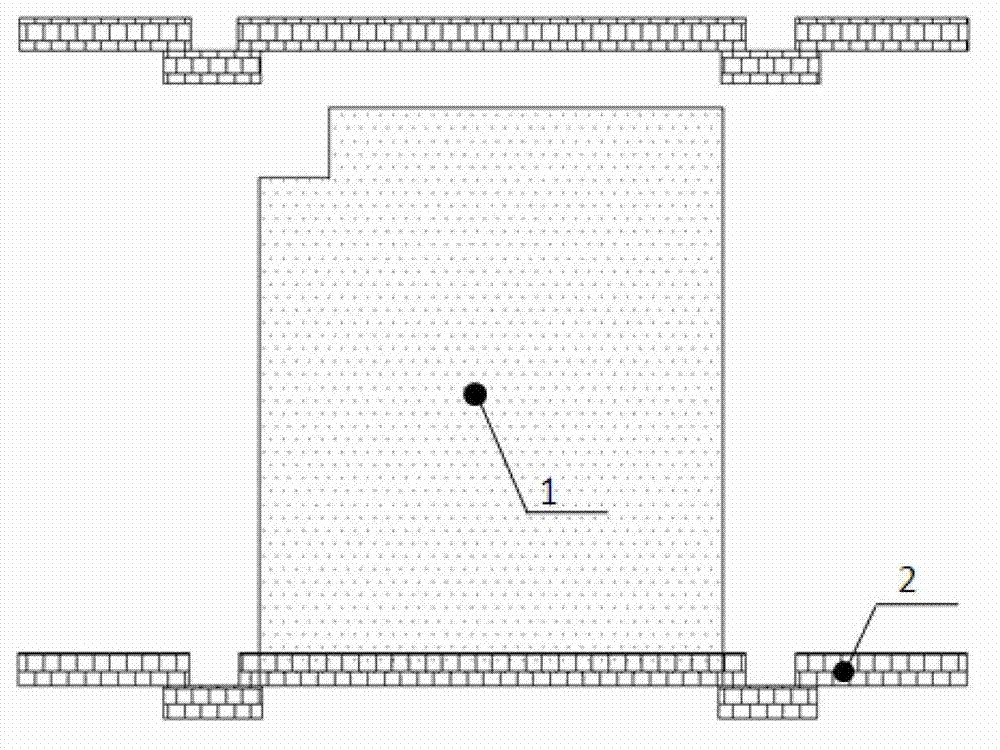

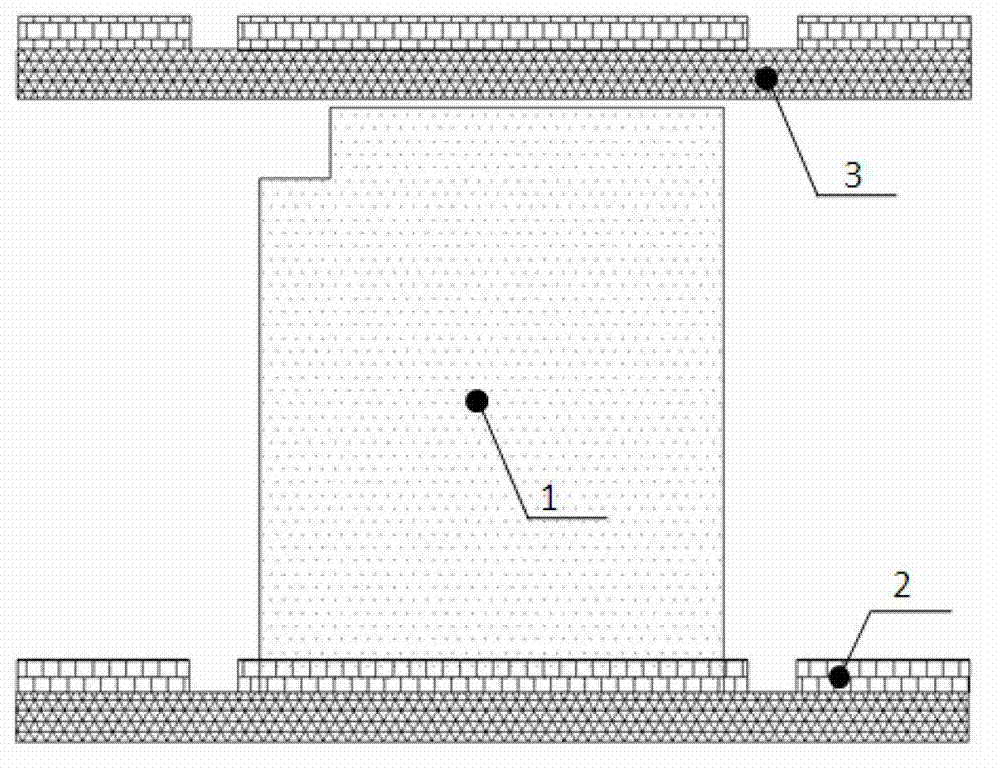

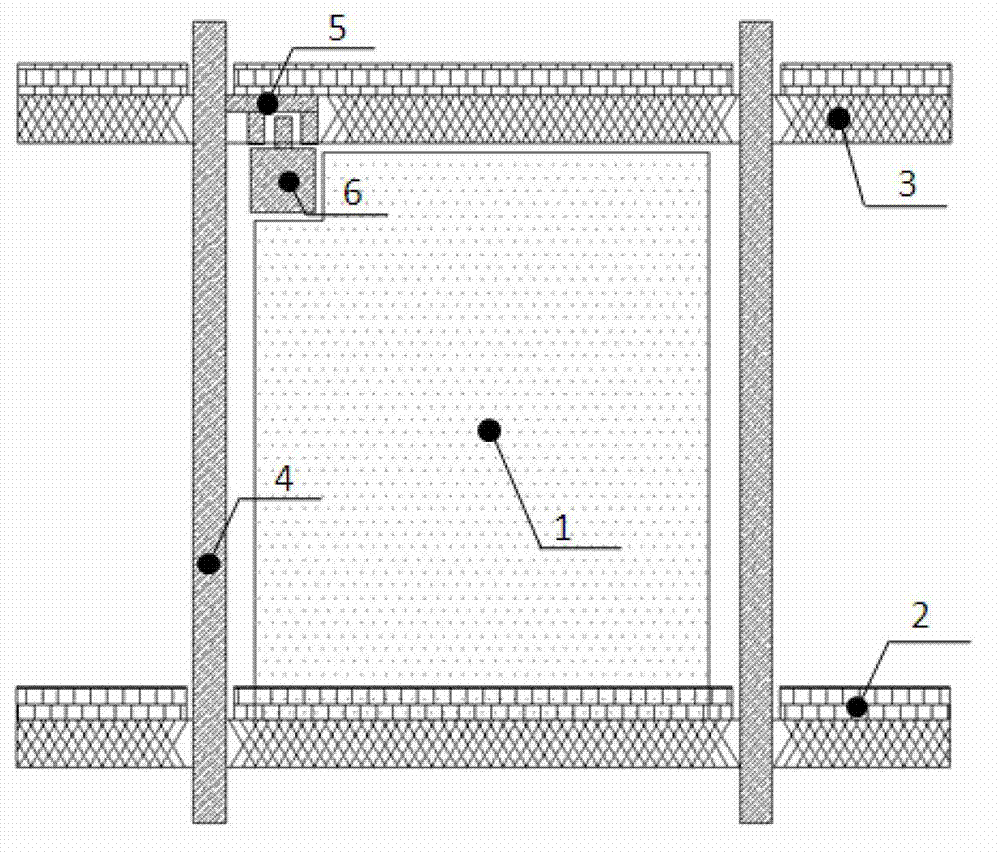

[0055] Combine below Figure 1 to Figure 5 , the method for manufacturing the array substrate in the present invention will be described in detail.

[0056] The array substrate manufacturing method in the embodiment of the present invention includes:

[0057] S1. Forming a transparent common electrode pattern and a common electrode line pattern on a base substrate;

[0058] Such as Image 6 with Figure 7 As shown, the array substrate of the embodiment of the present invention is fabricated on a base substrate 8, which is usually a glass substrate, a quartz substrate or a transparent resin substrate.

[0059] The pattern including the transparent common electrode 1 and the pattern of the common electrode line 2 are formed on the base substrate 8 . Specifically, first, a transparent conductive layer film (not shown in the figure) and a common electrode line metal layer film (not shown in the figure) are sequentially formed on the base substrate 8. In this embodiment, deposit...

Embodiment 2

[0101] The embodiment of the present invention also provides an array substrate, including gate lines 3, data lines 4, transparent common electrodes 1 and common electrode lines 2 formed on the substrate, and formed in the pixel area defined by the gate lines 3 and data lines 4. The pixel electrode 7 and the thin film transistor, wherein, a common electrode insulating layer 9 is formed between the common electrode line 2 and the gate line 3, so that the common electrode line 2 and the gate line 3 are distributed in different layers, so that the common electrode line 2 can be improved. The line width reduces the impedance of the common electrode line, which is conducive to the uniformity of the common electrode voltage and the rapid attenuation of voltage fluctuations.

[0102] Wherein, the overlapping area of the common electrode line 2 and the data line 4 on the horizontal plane is located on both sides of the gate line 3 . The above structure makes there is no direct overl...

Embodiment 3

[0105] The embodiment of the present invention also provides a display device, which includes the array substrate in the second embodiment, which improves the display quality of the display device.

[0106] Wherein, the display device may be any product or component with a display function such as a liquid crystal panel, a mobile phone, a tablet computer, a television set, a monitor, a notebook computer, a digital photo frame, and a navigator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com