Light guide plate

A technology of light guide plates and particles, applied in the field of light guide plates, can solve the problems of insufficient uniformity of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The structure and effect of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings.

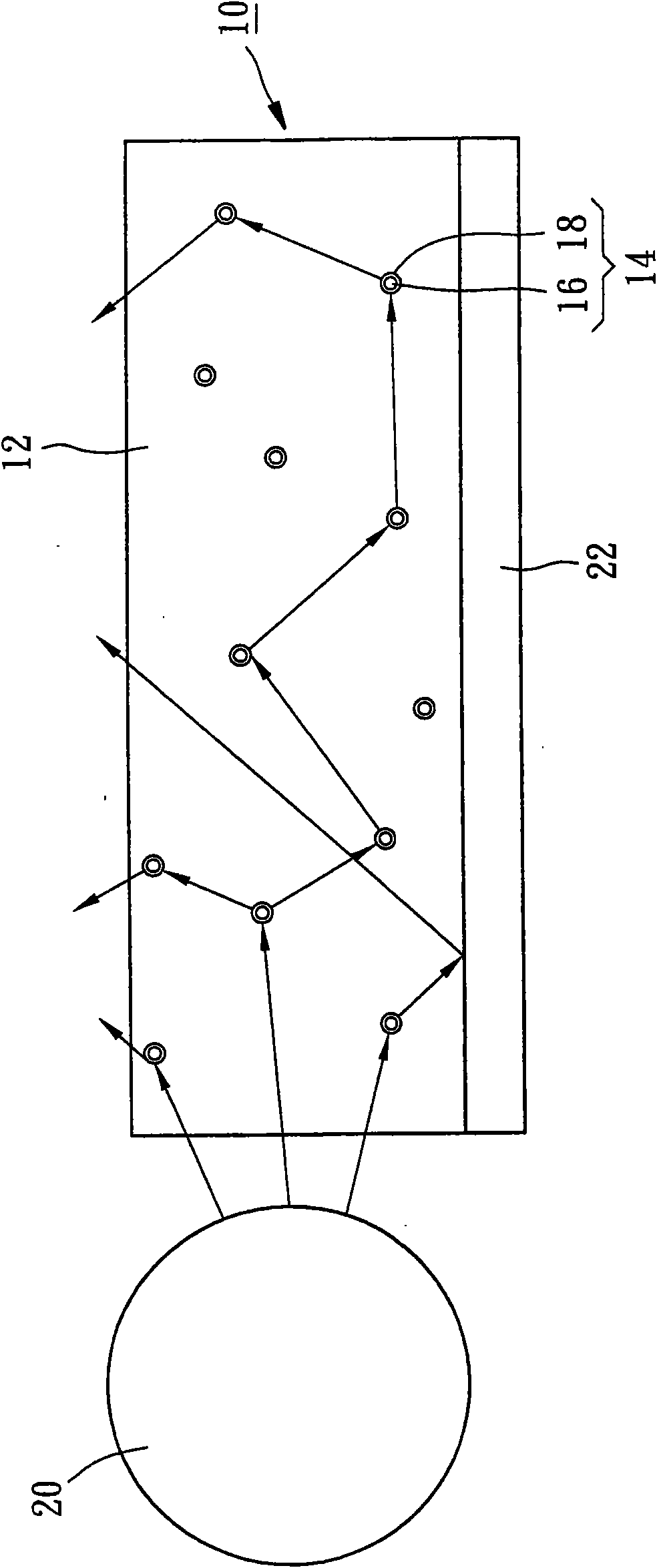

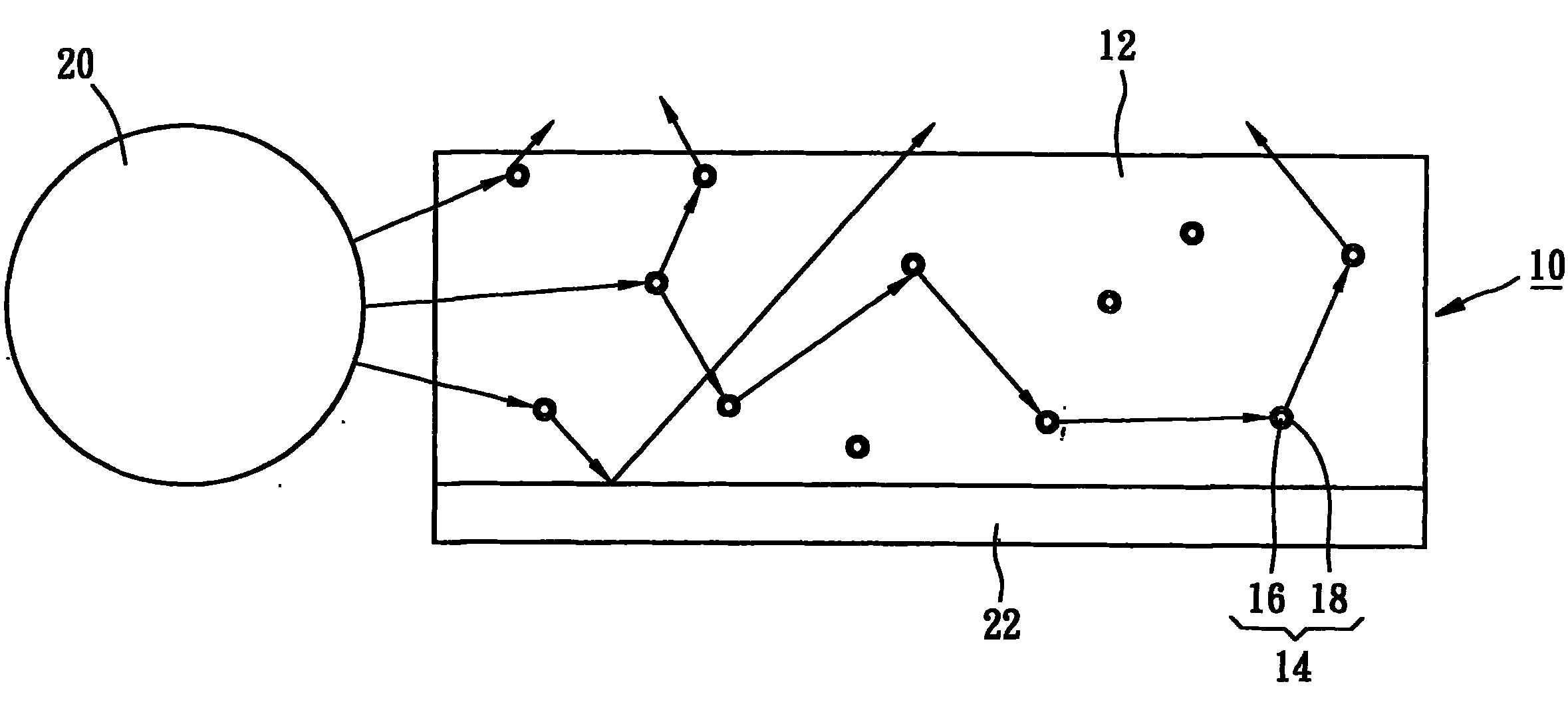

[0017] Such as figure 1 As shown, the light guide plate 10 provided by a preferred embodiment of the present invention includes a substrate 12 and a plurality of reflective particles 14 .

[0018] The substrate 12 is made of thermoplastics, such as methyl methacrylate resin, polyvinyl chloride or polystyrene, wherein the methacrylate resin contains polymethyl methacrylate (polymethyl methacrylate), polyethyl methacrylate, polypropyl methacrylate, polybutyl methacrylate or polypentyl methacrylate.

[0019] Each reflective particle 14 is spherical and uniformly dispersed in the substrate 12. According to the analysis results of HORIBA LB-500 high-concentration ultrafine particle size distribution analyzer (dynamic light scattering submicron particle size distribution analyzer), the average particle size of each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com