Optical flat structure achieving air imaging

An optical flat and imaging technology, applied in the optical field, can solve the problems of low practicability, insufficient display effect and interactive experience, and large energy loss, etc., to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

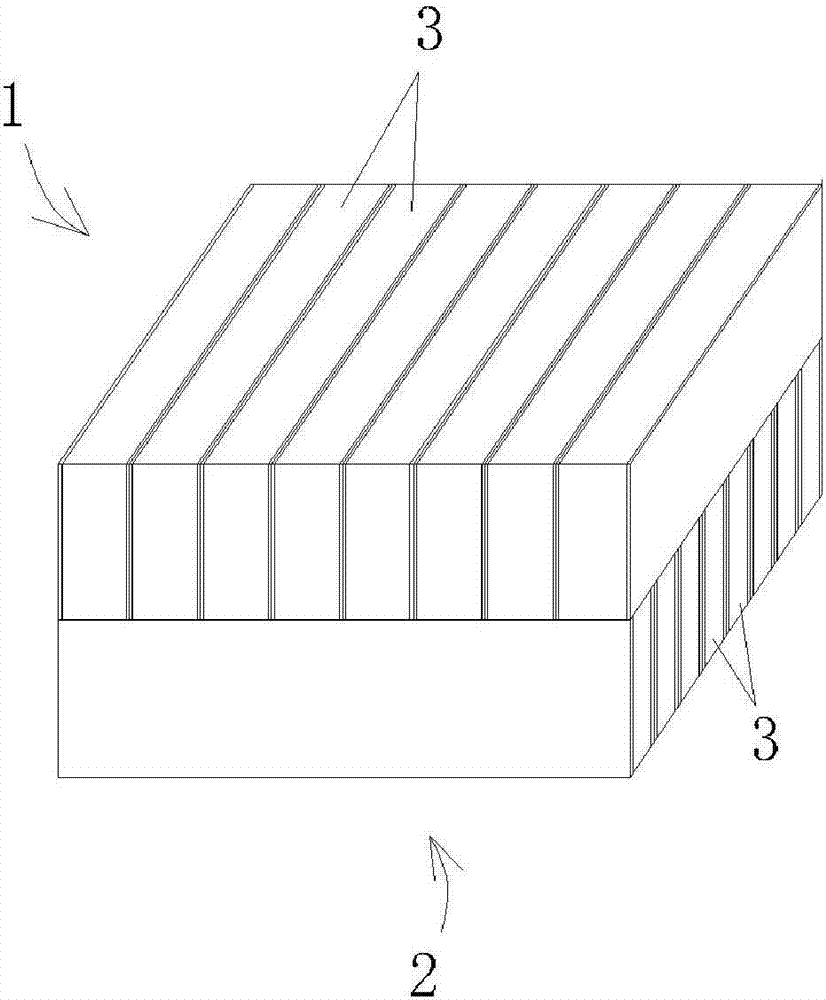

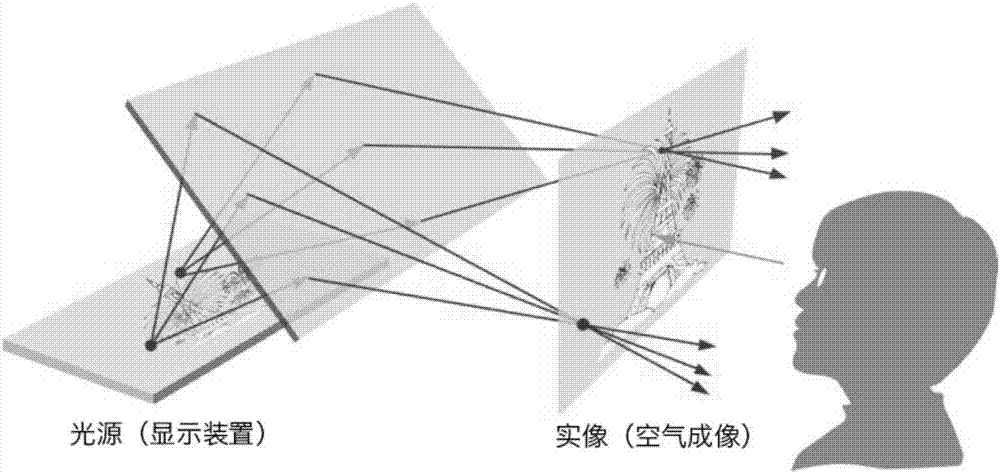

[0016] Such as figure 1 As shown, the optical flat plate structure for realizing air imaging includes an upper layer lens 1 and a lower layer lens 2 that are tightly bonded and stacked. Both the upper layer lens and the lower layer lens use a plurality of reflective strips 3 arranged in parallel. The reflective strips are perpendicular to the surface of the lens, and the upper layer The reflective strips of the lens and the reflective strips of the lower lens are arranged orthogonally to form a two-layer neatly arranged orthogonal mirror structure. The scattered light emitted by any point light source, plane light source and three-dimensional light source will pass through the lens with this special structure. The same position on the other side of the lens re-converges the image, refer to image 3 and 5 .

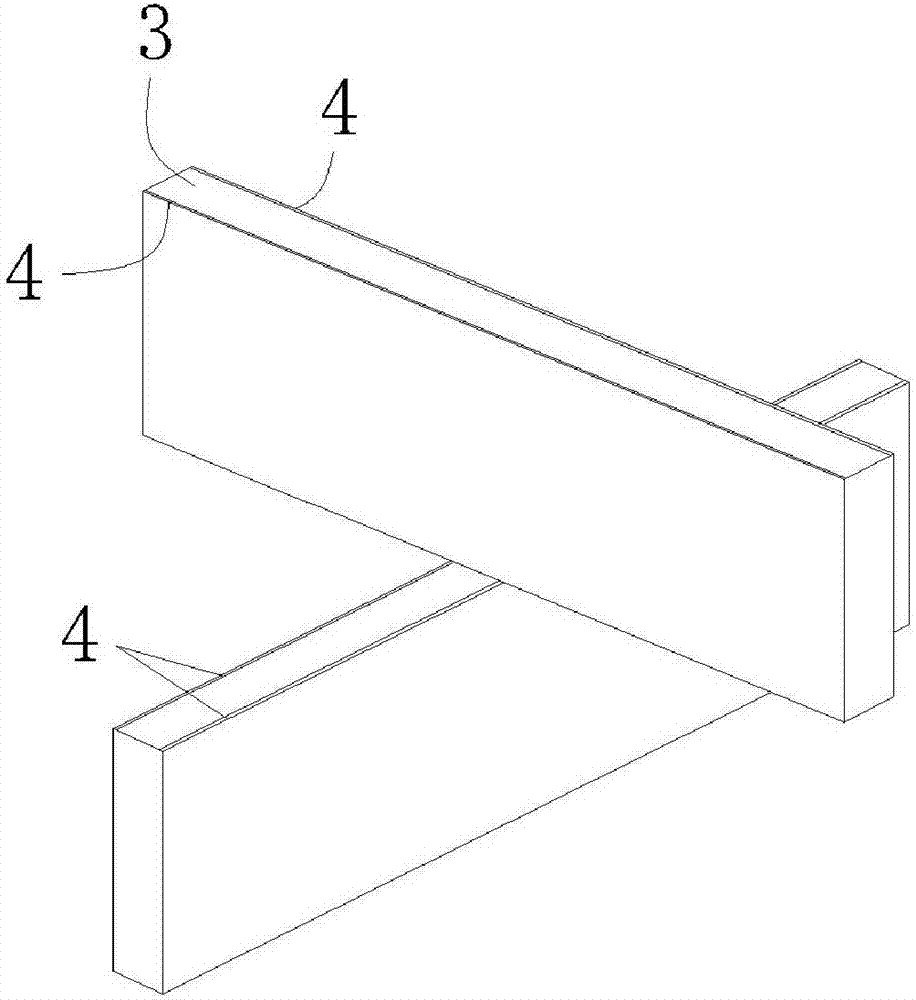

[0017] Such as figure 2 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com