Bus capable of automatically tightening to avoid inertia influence on passengers

A technology for buses and passengers, which is applied to vehicle components, special positions of vehicles, transportation and packaging, etc., and can solve the problems of passenger dumping, single function, simple handrail structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

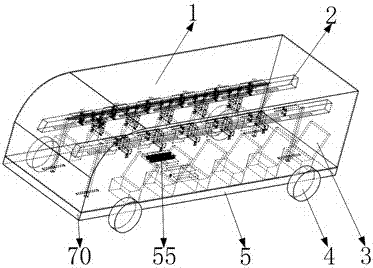

[0060] Such as figure 1 As shown, it includes chassis mechanism 70, compartment mechanism 1, seat 3, armrest mechanism 2, such as figure 1 As shown, wherein the compartment mechanism 1 is installed on the upper side of the chassis mechanism 70; as figure 1 As shown, two rows of seats 3 are installed on the inner end face of the compartment mechanism 1; figure 1 As shown, the two armrest mechanisms 2 are installed on the upper side of the chassis mechanism 70 , and the two armrest mechanisms 2 are located between the two rows of seats 3 .

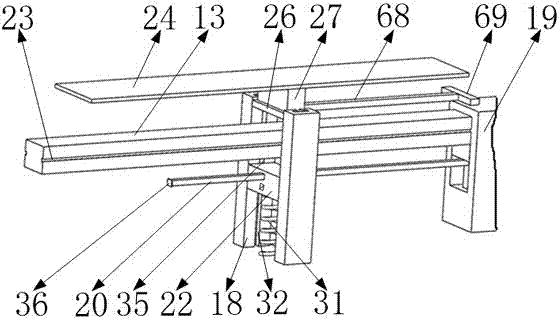

[0061] Such as figure 2 As shown, the above-mentioned chassis mechanism 70 includes a wheel 4, a base 5, a first T-shaped slot 10, side lugs 11, a fixing groove 12, a fourth spring 55, and a winding mechanism 56, such as Figure 4 , 5 As shown, wherein the center of the upper end face of the base 5 has a first T-shaped slot 10; as Figure 5 As shown, the four side lugs 11 are symmetrically installed on both sides of the end face of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com