Coplanar bonding structure and preparation method thereof

A bonding structure and coplanar technology, applied in the field of coplanar bonding structure and its preparation, can solve the problems of inability to guarantee reliable connection of bonding frame, mechanical damage and destruction of lead pads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0120] The invention provides a method for preparing a coplanar bonding structure, the preparation method comprising the following steps:

[0121] a) Provide a device structure to be bonded, the device structure includes at least two defined functional areas, wherein each of the functional areas has a surface to be extracted, and at least two of the surfaces to be extracted are located at different heights on flat surface;

[0122] b) Leading each of the faces to be led out to a plane of the same height through a laminated structure formed alternately by insulating layers and metal layers to form each bonding lead-out face, so as to obtain the coplanar bonding structure.

[0123] Specifically, using the stacked structure to lead each of the faces to be extracted to the same plane means that the deposited material at the lower position is lifted in the longitudinal direction by forming the stacked structure during the device formation process. High enough to be integrated with...

Embodiment 1

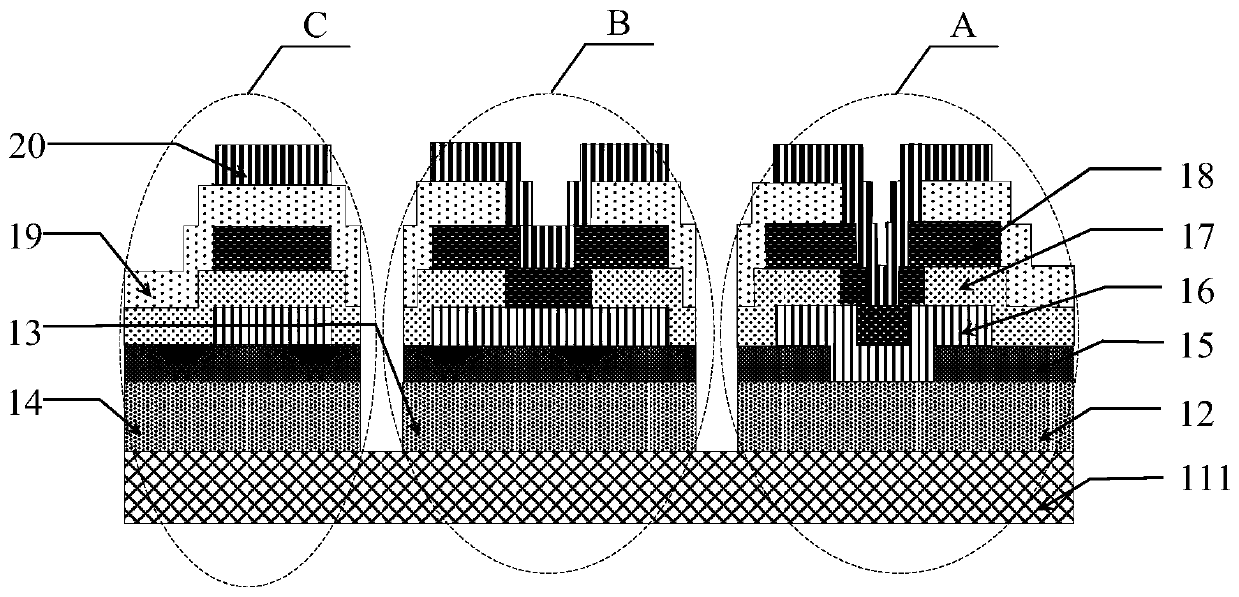

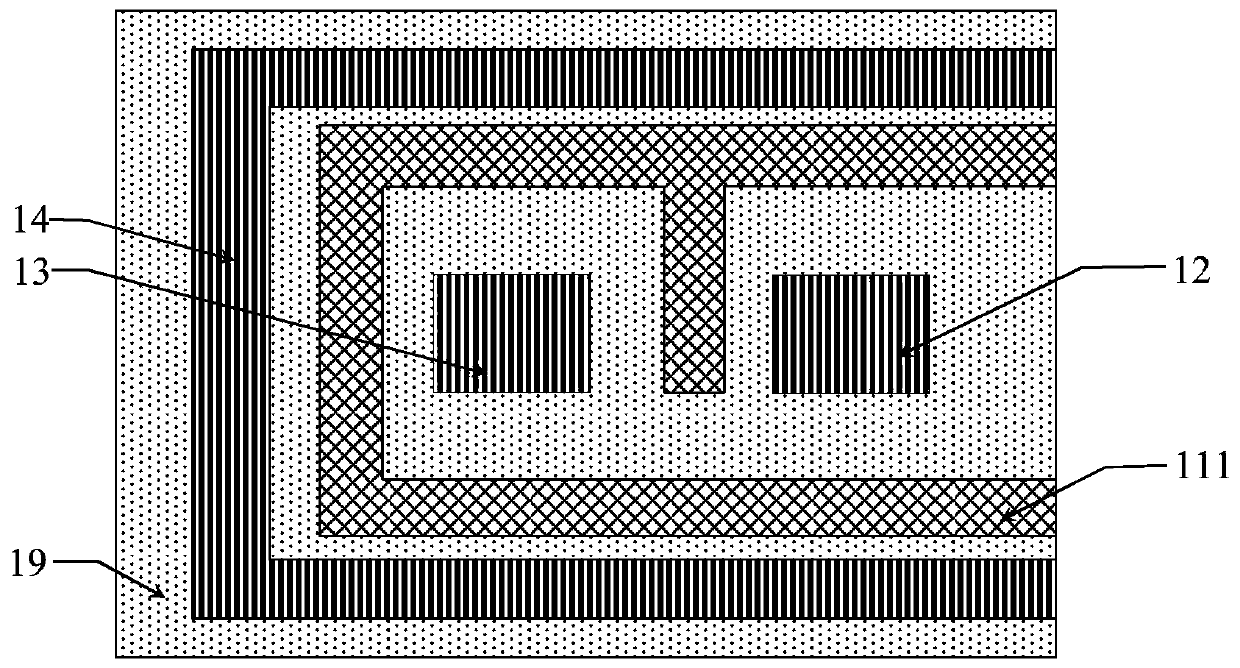

[0135] Such as Figure 1-12 As shown, this embodiment 1 provides a method for preparing a coplanar bonding structure, and the preparation method includes the following steps:

[0136] Such as figure 1 , figure 2 as well as Figure 5 As shown, step 1) is performed to provide a substrate 11, on which a first functional area A, a second functional area B and a third functional area C are defined independently of each other, wherein the third functional area The shape of C is a closed ring structure (the schematic diagram of its partial structure is shown in the figure), wherein, the ring structure can be a square ring or a ring, depending on specific needs, and no specific limitation is made here. A functional area A and the second functional area B are sequentially arranged in the ring structure;

[0137] Specifically, the substrate 11 provides an initial plane of the same height, and the substrate 11 can be any desired structure. In addition, in this embodiment, the second...

Embodiment 2

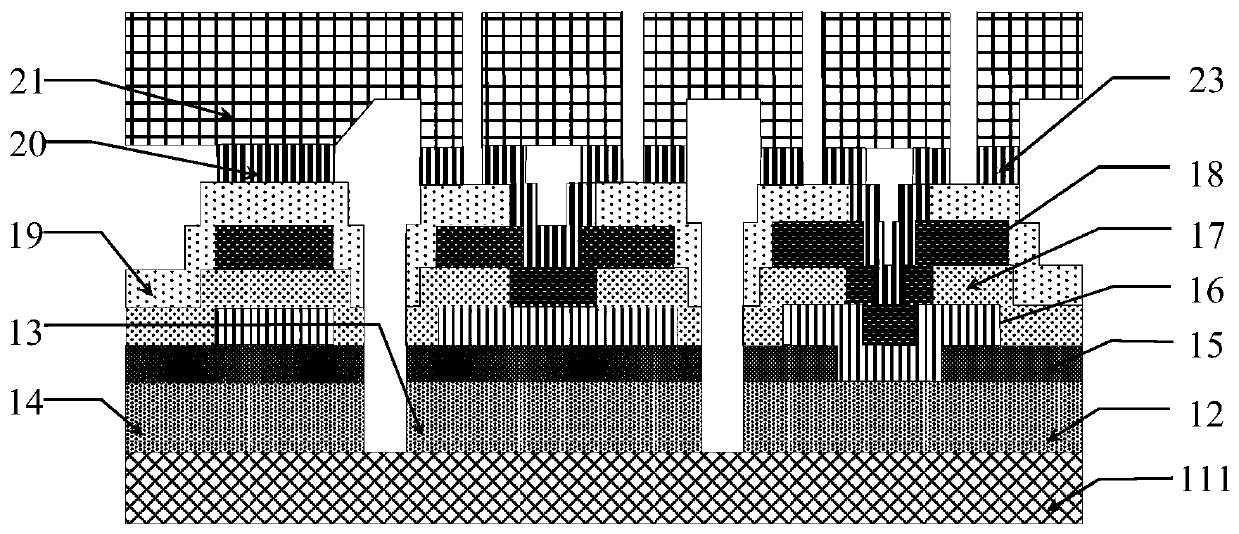

[0162] Such as Figures 13 to 14 As shown, this embodiment 2 provides a method for preparing a coplanar bonding structure. The difference between the coplanar bonding structure in this embodiment 2 and the coplanar bonding structure in embodiment 1 includes the setting of the stacked structure, Other structures and preparation steps are the same or similar to those of Embodiment 1. Refer to the relevant drawings of Embodiment 1. The preparation method includes the following steps:

[0163] 1) Provide a substrate 11 on which a first functional area, a second functional area and a third functional area are defined;

[0164] 2) Depositing a first insulating layer 15 on the substrate 11, and etching at the position corresponding to the first functional area, exposing part of the substrate to form a first electrode lead-out window 151 with a predetermined width, so as to obtain The surface to be led out of the first functional area;

[0165] 3) Deposit the first metal layer 16 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com