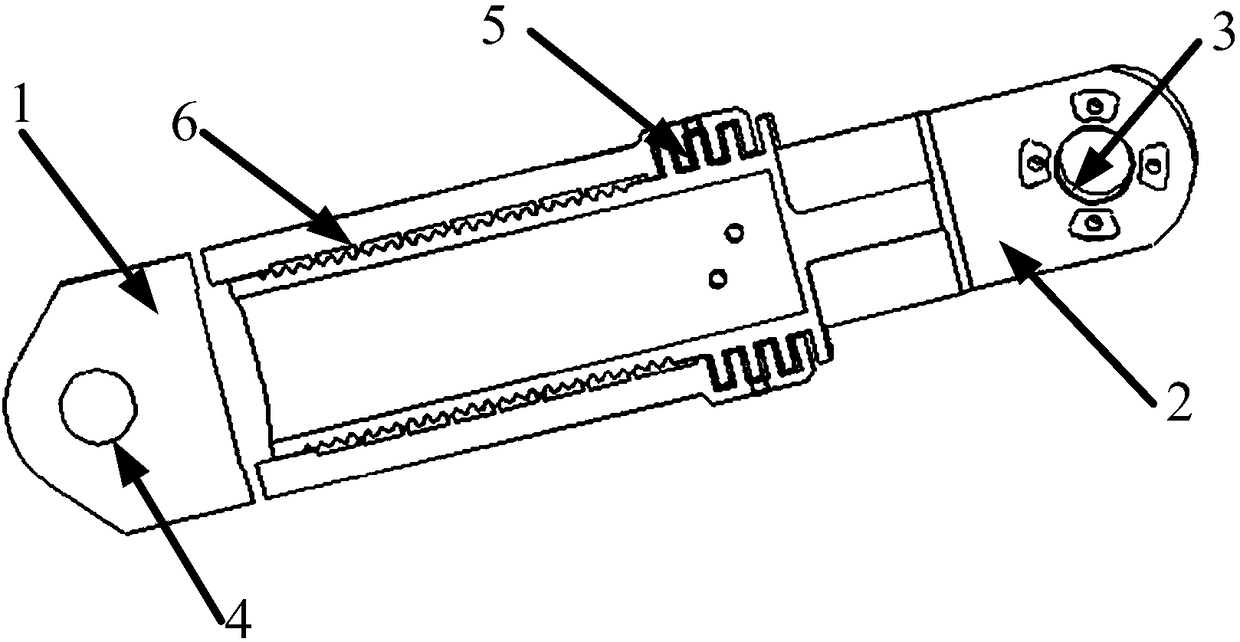

An improved damping and vibration isolation device for remote sensors based on bi-pod support

A support method and remote sensor technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., to achieve the effects of stable support stiffness, effective and accurate adjustment, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

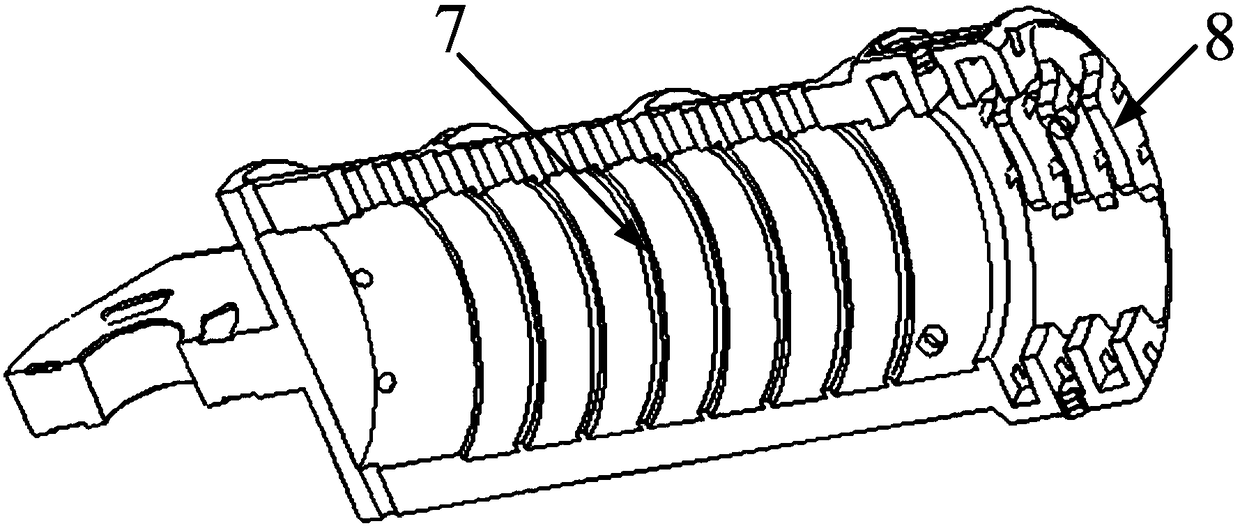

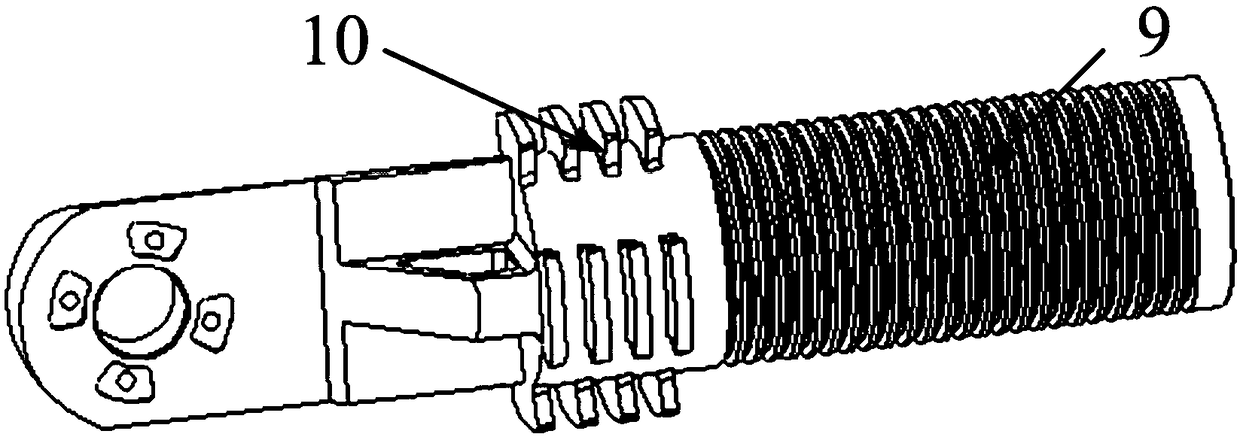

[0027] The invention provides an improved remote sensor damping and vibration isolation method based on the bi-pod support mode, which avoids complicated control methods such as electric control, thermal control, telemetry, and remote control, has high vibration reduction efficiency, consumes less system resources, and achieves The rigid support structure and the damping vibration damping structure are functionally separated to avoid the technical problem that the stiffness of the vibration isolation system is difficult to effectively maintain after the damping layer is affected by the space environment. In addition, the damping vibration isolation system is sealed and coated with multilayer heat insulation materials , Solve the problem of temperature retention in the working section of the damping vibration isolation system, and at the same time real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com