Dust collector equipment

A technology for dust collectors and equipment, which is applied in the direction of electrical components, coupling devices, circuits, etc., and can solve the problems that the electrical connector cannot be automatically ejected, the power supply connection is unstable, and the dust collector is damaged when it is powered off, so as to achieve good power supply stability and structure Simple, safe and stable power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

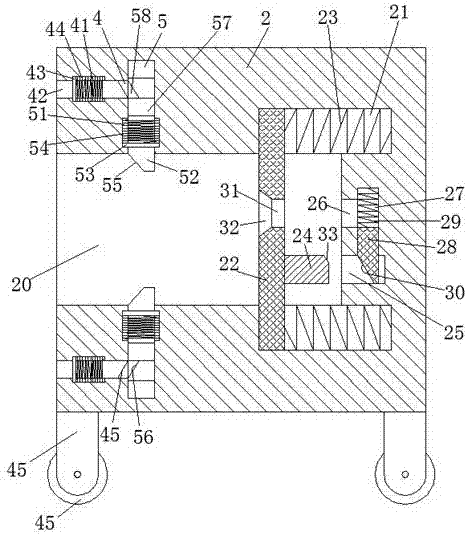

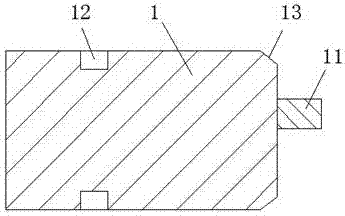

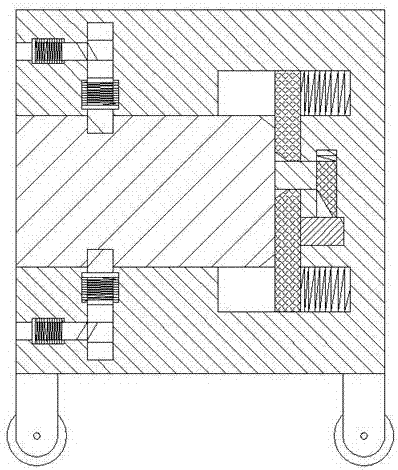

[0021] refer to Figure 1-5 The shown dust remover equipment includes an electrical connection head 1 and a power transmission frame 2, an electric contact block 11 is arranged on the right end surface of the electrical connection head 1, and two oppositely arranged upper and lower ends of the electrical connection head 1 A locking groove 12, the bottom of the power transmission frame 2 is provided with a column 45, the bottom of the column 45 is rotatably installed with a roller 46, and the power transmission frame 2 is conveniently moved by the roller 46, and the left end surface of the power transmission frame 2 is provided There is a latch sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com