Coal and gas outburst dynamic disaster-induced visual physical simulation test system

A technology of gas outburst and physical simulation, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of single data collection, insufficient visualization, and inability to simulate the mine network structure, and achieve the effect of comprehensive data collection and sufficient visualization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

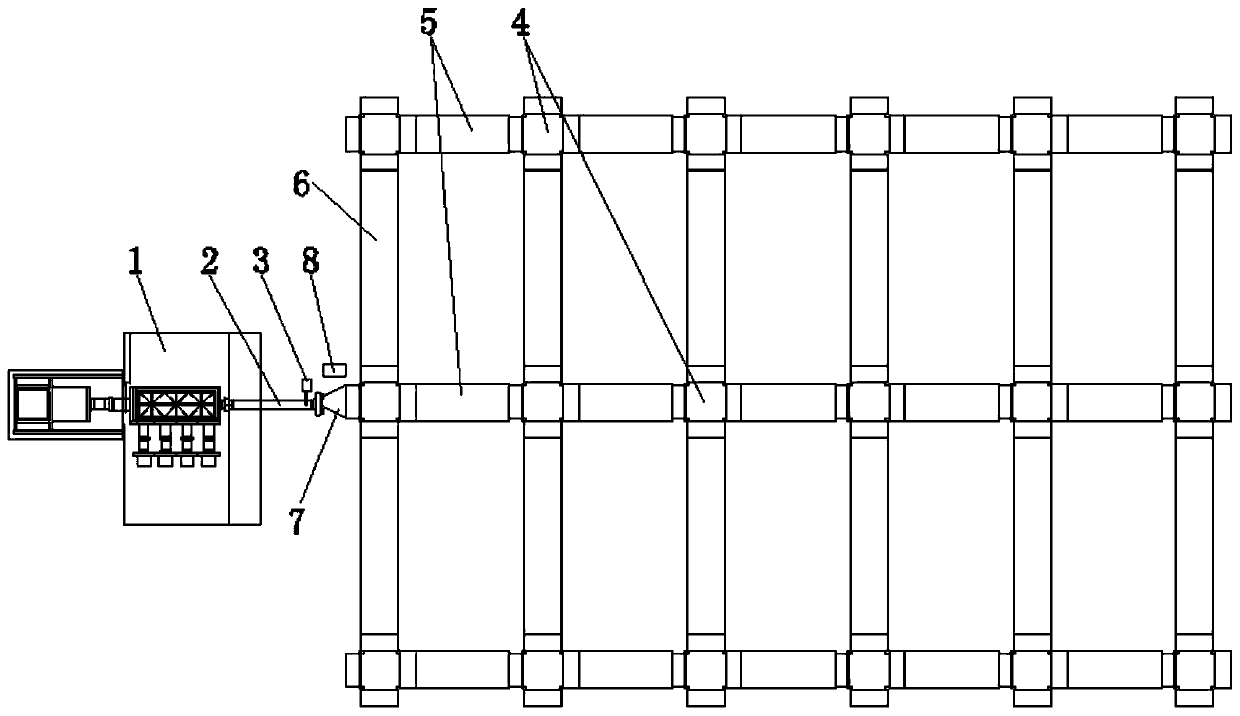

[0069] Such as figure 1 As shown, the present invention includes two parts: "multi-field coupling large-scale coal and gas outburst simulation test platform" and "coal and gas outburst dynamic disaster visualization test roadway system". Among them, the simulation test bench 1 adopts the existing technology, and its structure will not be repeated here. There is a simulated test box on the simulated test bench 1, the protruding opening of the simulated test box is connected with the front port of the guide tube 2 through the holder, and there is an air-filled hole on the holder, and there are two Rupture disc with a gap between the two rupture discs. A flow meter 3 is installed near the rear end of the guide tube 2 .

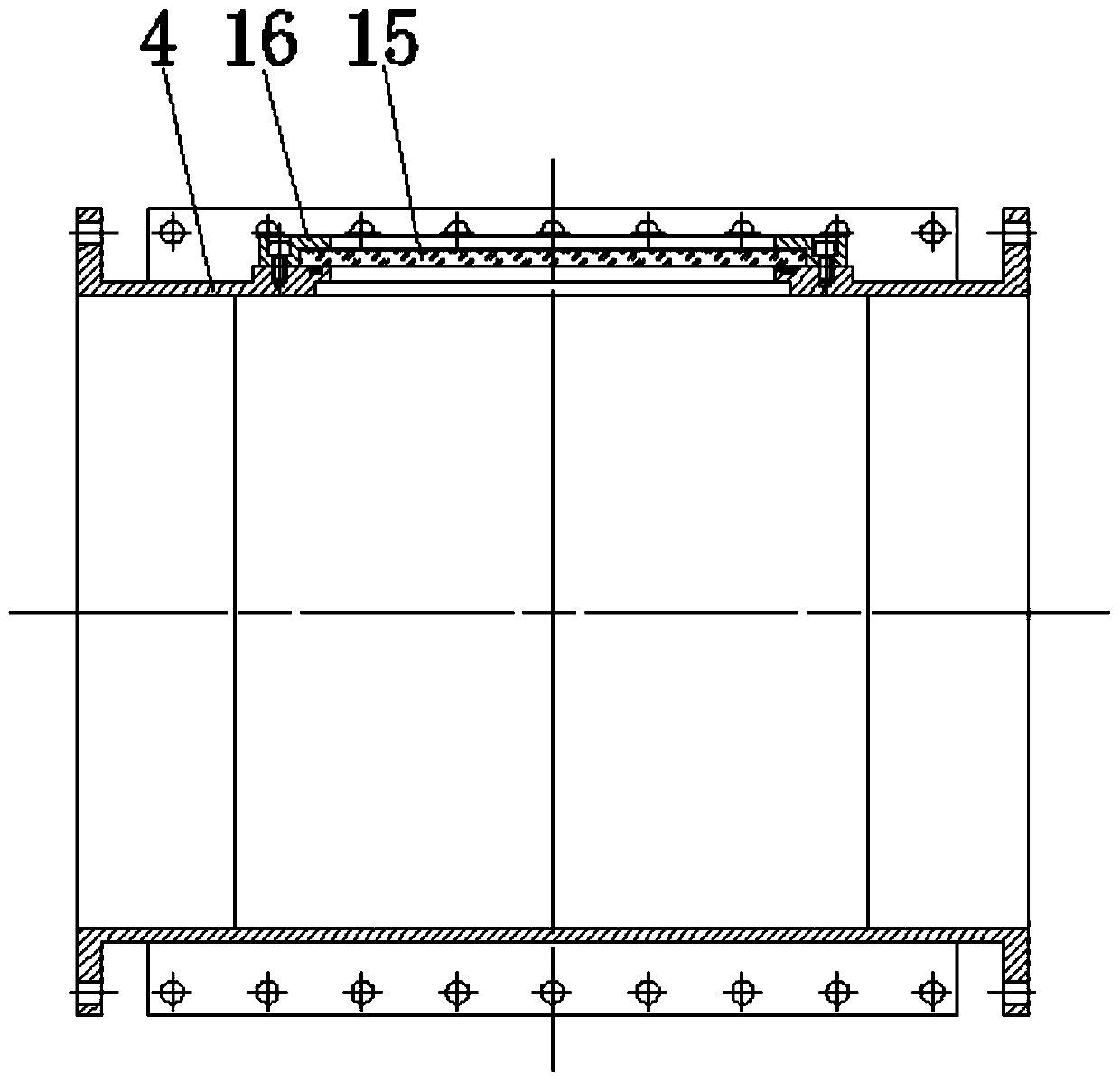

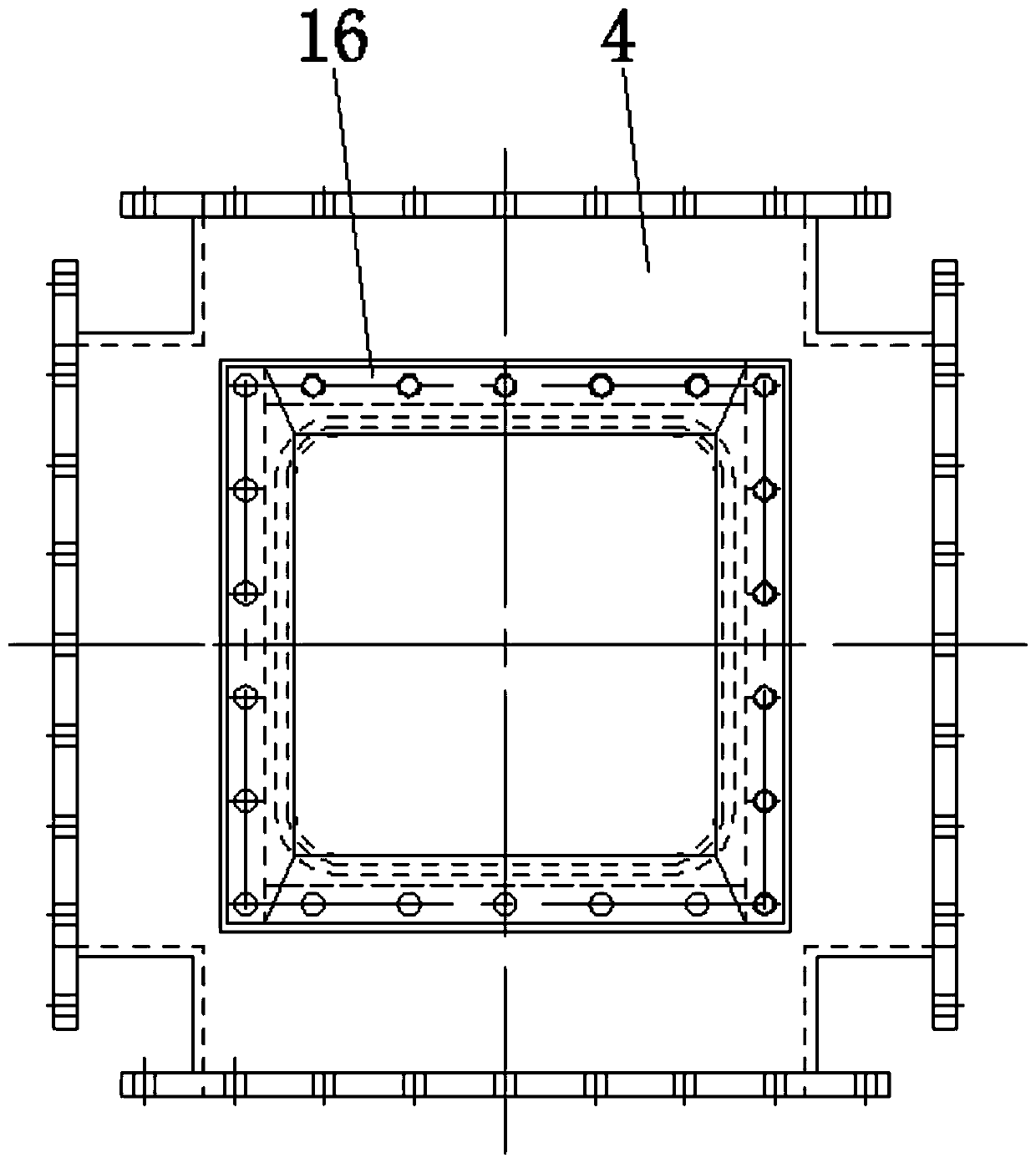

[0070] Such as figure 1 , figure 2 , image 3 As shown, the roadway system is a simulated roadway pipe network arranged behind the guidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com