A method for improving oil cleanliness by adding a small amount of water to rolling oil

A technology of rolling oil and cleanliness, applied in the direction of lubricating compositions, etc., can solve problems such as poor cleanliness, achieve production safety, improve filtering effect, and stabilize product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for adding a small amount of water in rolling oil to improve the cleanliness in the oil, comprising the following steps:

[0021] 1. Establish light transmittance index to characterize the content of impurities in rolling oil.

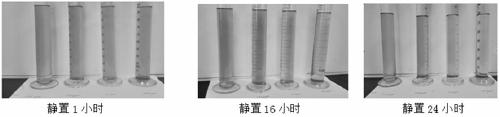

[0022] In the actual production process, it is difficult to filter particles and impurities smaller than 2 μm. In order to facilitate the evaluation of cleanliness, a TU-1810 UV-Vis spectrophotometer was used to measure the light transmittance of the rolling oil to characterize the content of impurities in the oil.

[0023] 2. Take the clean oil sample filtered by the rolling oil filtration system, and carry out water configuration. The method of configuration is as follows:

[0024] (1) Take the same oil sample and add different amounts of trace deionized water through atomization;

[0025] (2) Use FLUKO FA25 centrifuge to fully stir it, in order to ensure the uniformity of water in the oil, the high-speed shear speed is 16000rpm, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com