Escape compartment

An escape cabin and survival cabin technology, applied in the field of escape cabins, can solve the problems of reduced comfort, weak impact resistance, and large space occupation, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

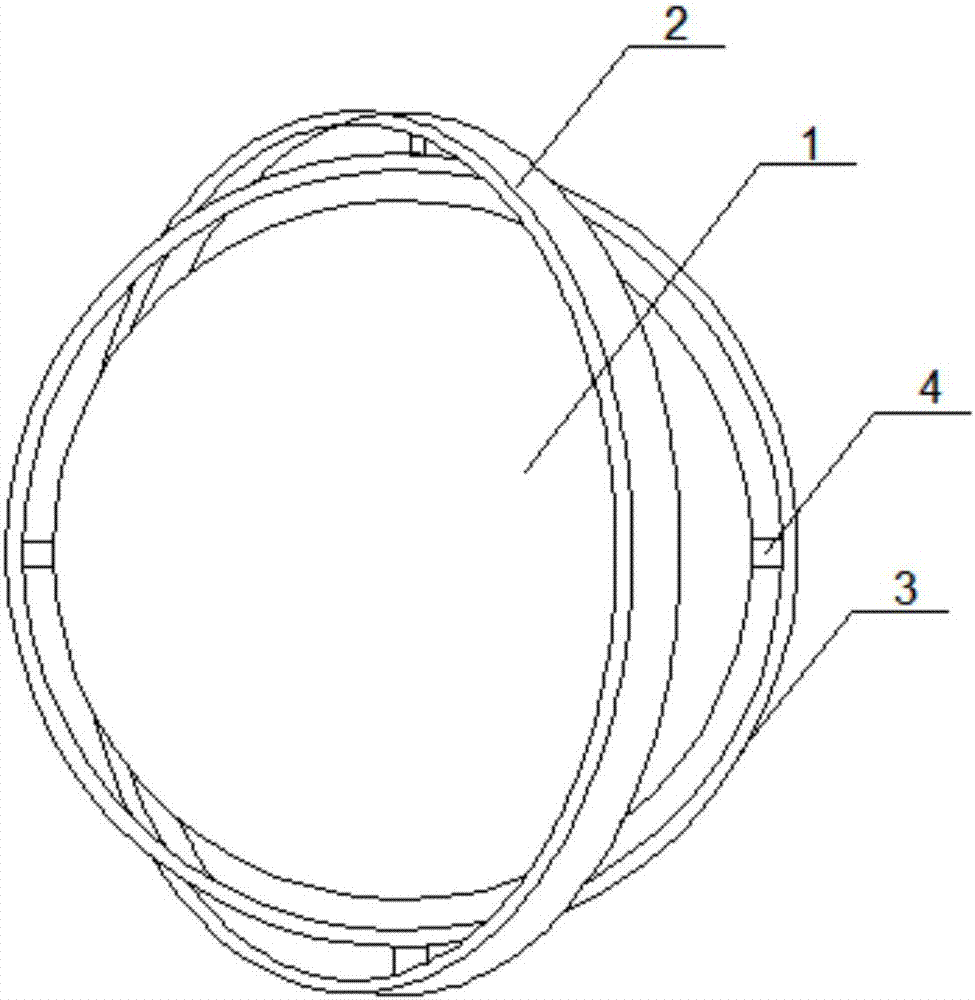

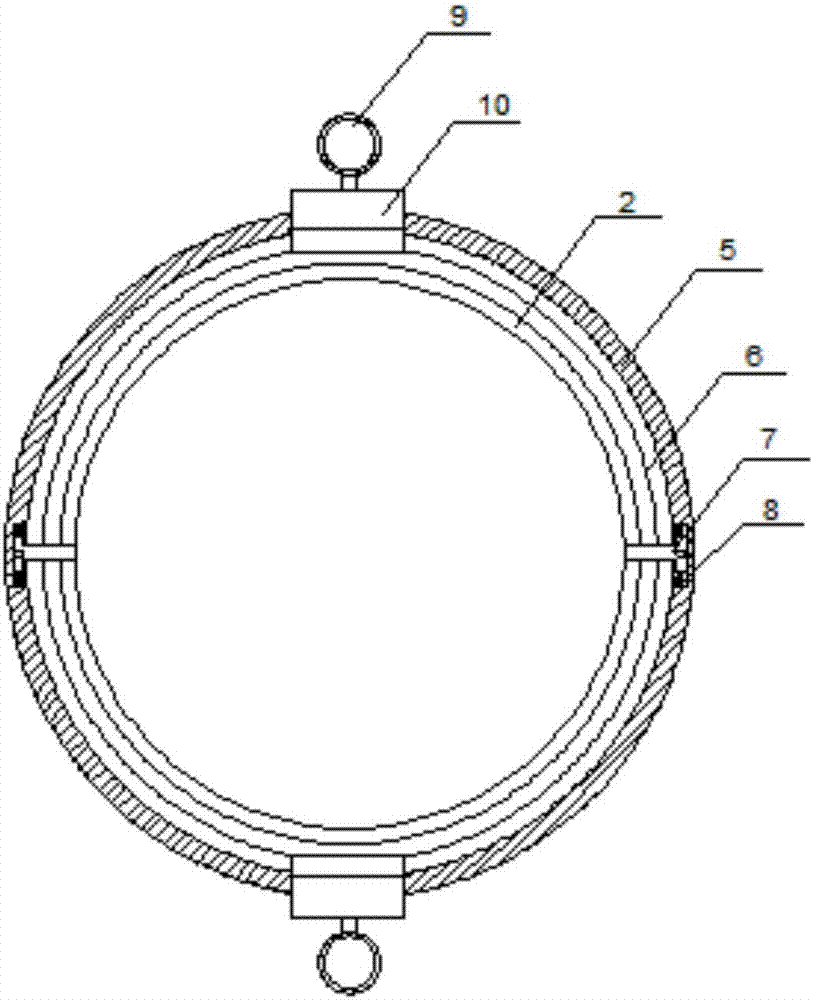

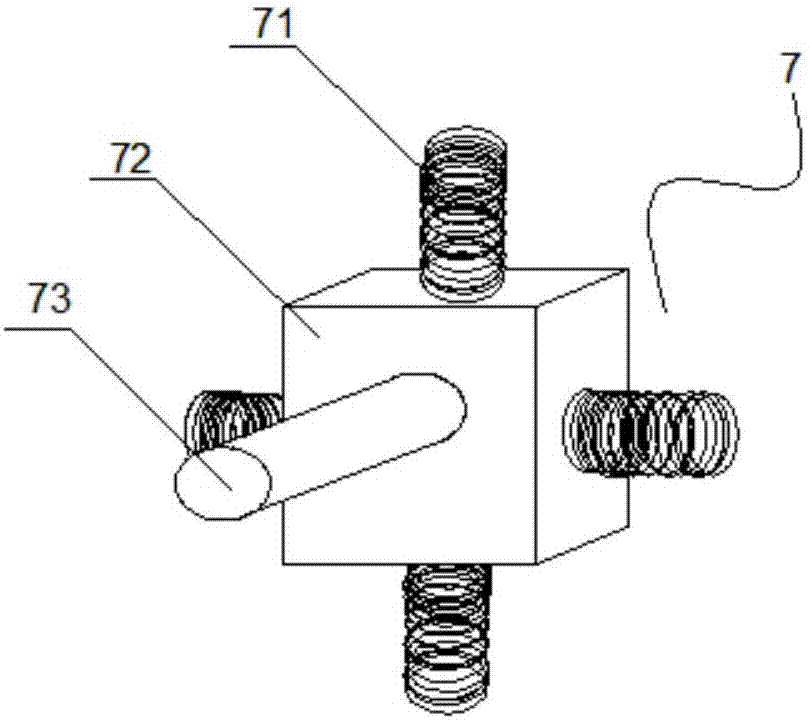

[0025] The present invention provides an escape cabin, such as figure 1 and figure 2 As shown, it includes a spherical survival cabin 1, a universal mechanism and a spherical outer shell 5. The survival cabin 1 is installed inside the universal mechanism, and the outside of the universal mechanism is installed in the outer shell 5. The top and bottom of the outer shell 5 are arranged symmetrically. There are connecting terminals 10, and the outer shell 5 includes several arc-shaped plates, the two ends of the arc-shaped plates are respectively fixedly connected to the upper and lower connecting terminals 10, and the inner side of the arc-shaped plates is provided with a reinforcement skeleton 6, and the reinforcement skeleton 6 is installed at a corresponding interval. The inner side of the curved plate, the reinforcement frame 6 is made up of some curved steel pipes, the top and bottom of the curved steel pipes are fixedly connected to the upper and lower connection terminal...

Embodiment 2

[0039] The difference between this embodiment and embodiment 1 is that, as image 3 As shown, it also includes a peripheral frame 13 , and the outer shell 5 is symmetrically provided with several connecting ends, and the connecting ends are connected to the inner side of the peripheral frame 13 through elastic cords 12 .

[0040] The above-mentioned technical scheme makes the survival cabin 1 have a certain cushioning effect, and the peripheral frame 13 can withstand a certain external force, thereby ensuring the safety of the survival cabin 1; in addition, there is a certain space between the peripheral frame 13 and the outer shell 5, so that There is enough space for the people in the survival cabin 1 to escape, so as to prevent the hatch door on the outer casing 5 from being stuck by external objects, so that the people in the survival cabin 1 cannot escape.

[0041] Furthermore, the outside of the peripheral frame 13 is covered with a flame retardant board 11 , and the fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com