A Gradual Fluidization Adaptive Horizontal Ultra-High Pressure Abrasive Jet Generating Device

A generating device and abrasive jet technology, which is applied in the direction of abrasive feeding device, used abrasive processing device, explosion generating device, etc., can solve the inconvenient vertical method that cannot realize screw precision conveying and throttling output mortar Arrangement of abrasive tanks, inability to accurately control mortar concentration and other problems, to avoid instability of mortar concentration, reduce fluctuation range of mortar output concentration, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

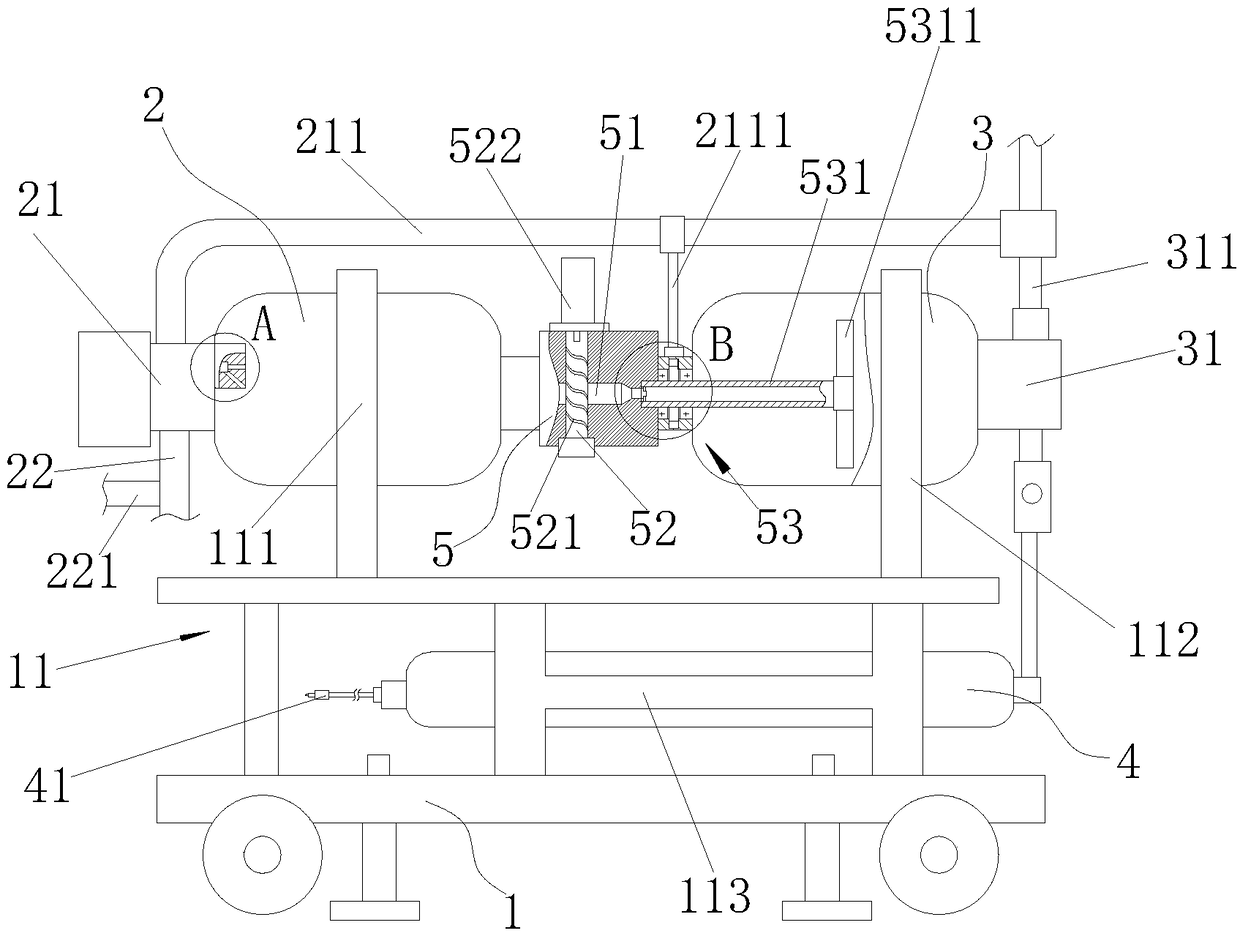

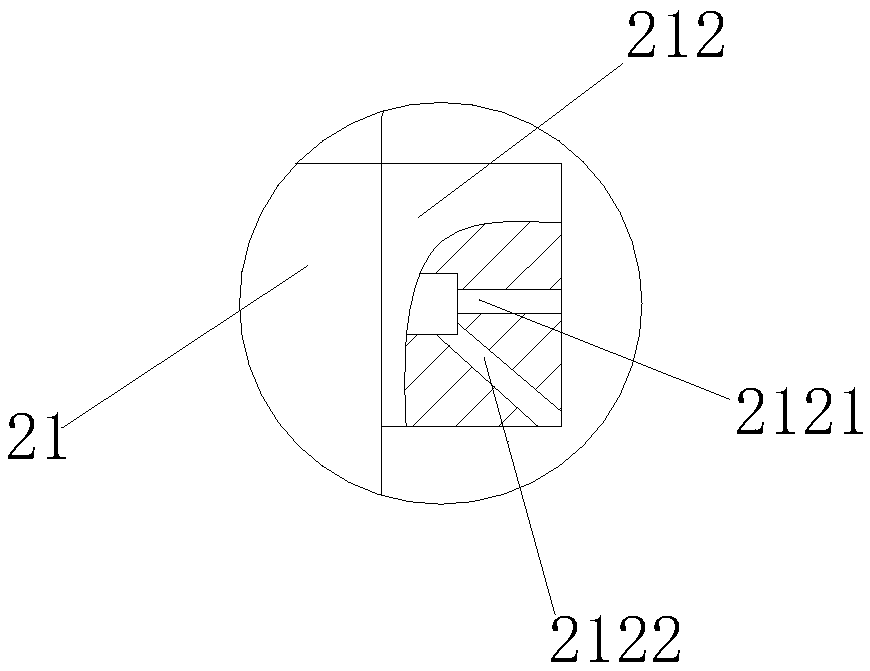

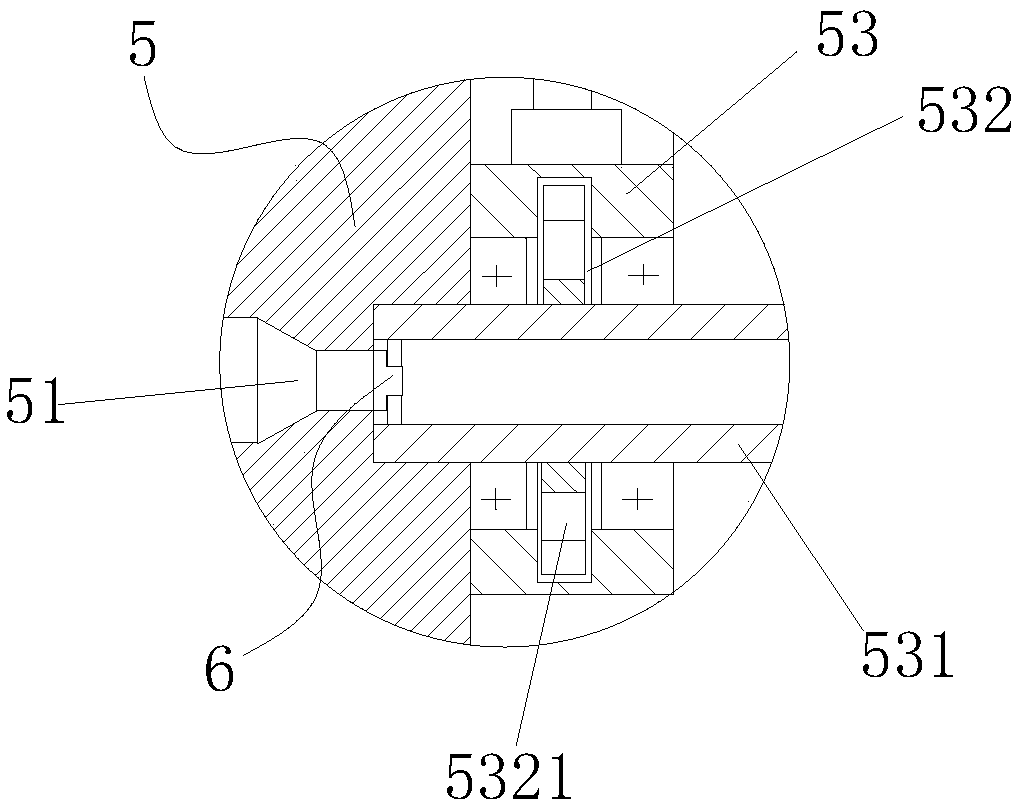

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4As shown, the gradual fluidization self-adaptive horizontal ultra-high pressure abrasive jet generating device includes a fixed-mobile dual-purpose vehicle 1, wherein it also includes a horizontal low-pressure sand tank 2, a horizontal self-adaptive mortar fluidization Tank 3 and horizontal ultra-high pressure tank 4, the axis of horizontal low-pressure sand tank 2, the axis of horizontal self-adaptive mortar fluidization tank 3 and the axis of horizontal ultra-high pressure tank 4 are all perpendicular to fixed-mobile dual-purpose vehicle 1 The lines are perpendicular to each other, the left end of the horizontal low-pressure sand tank 2 is equipped with an end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com