Process and device for preparing hydrogen peroxide

A hydrogen peroxide and preparation technology, applied in the field of chemical technology, can solve the problems of insufficient combination of pure water and oxidizing liquid, unstable hydrogen peroxide concentration coefficient, low hydrogen peroxide concentration, etc., to improve the liquid mixing effect, Solve the effect of production capacity and production safety, simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1, hydrogen peroxide preparation process, comprises the following steps:

[0048] S1. The working fluid from the circulating working fluid pump is firstly filtered through the secondary filter of the circulating working fluid filter to remove possible solid impurities, then preheated to the required temperature, and the hydrogen from the hydrogen section purified by the hydrogen filter enters at the same time Hydrogenation tower: According to the hydrogenation efficiency during the hydrogenation reaction, the working liquid and hydrogen enter the top of the previous tower first, flow down through the palladium catalyst layer in the tower, flow out from the bottom of the tower, and then enter the next tower through the connecting pipe outside the tower The top flows out from the bottom of the tower and enters the hydrogenated liquid gas-liquid separator;

[0049] S2. The hydrogenated liquid and unreacted hydrogen from the hydrogenation tower enter the hydrogen...

Embodiment 2

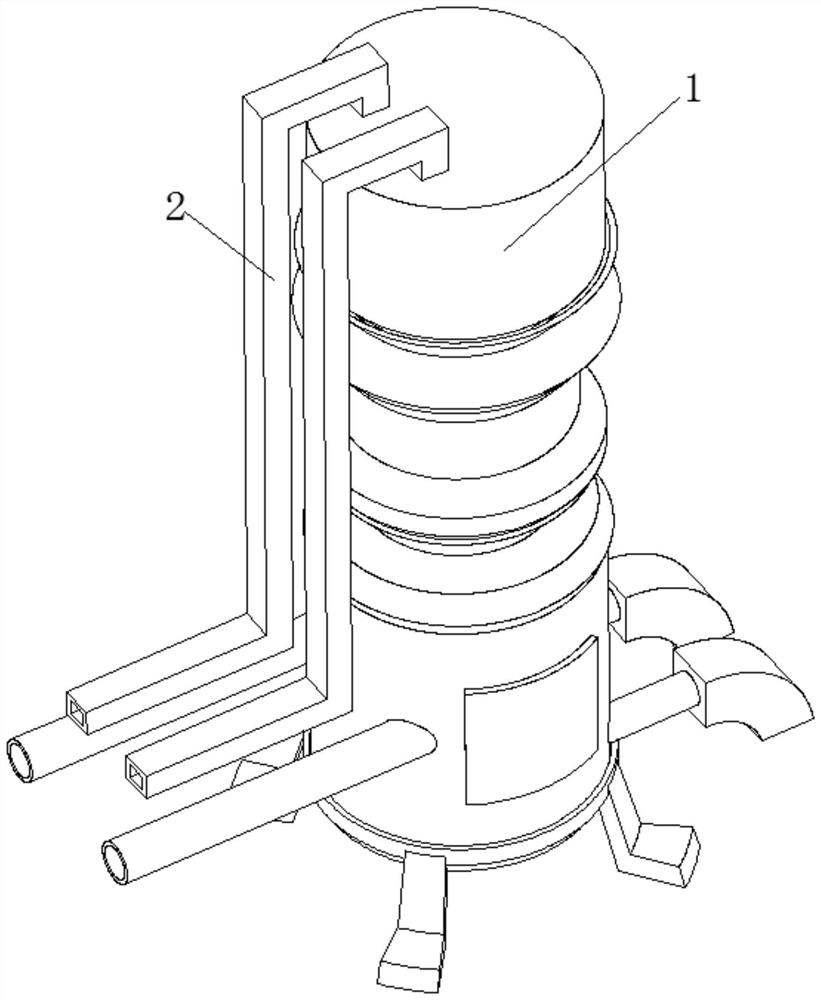

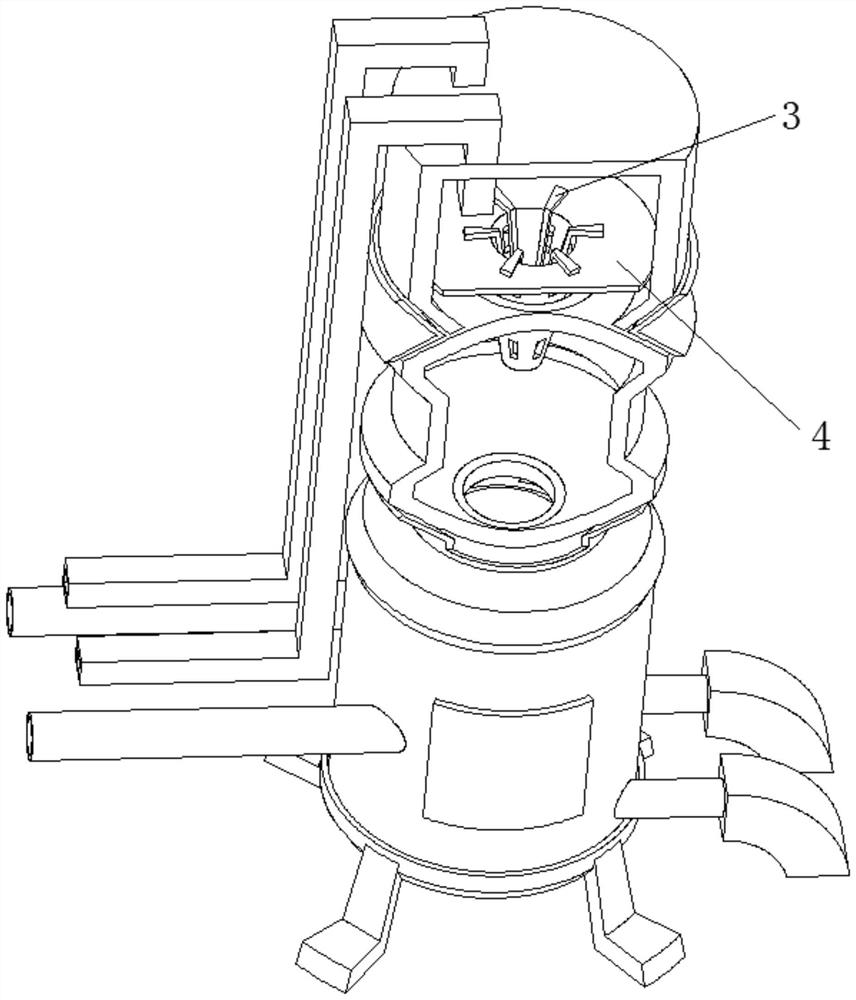

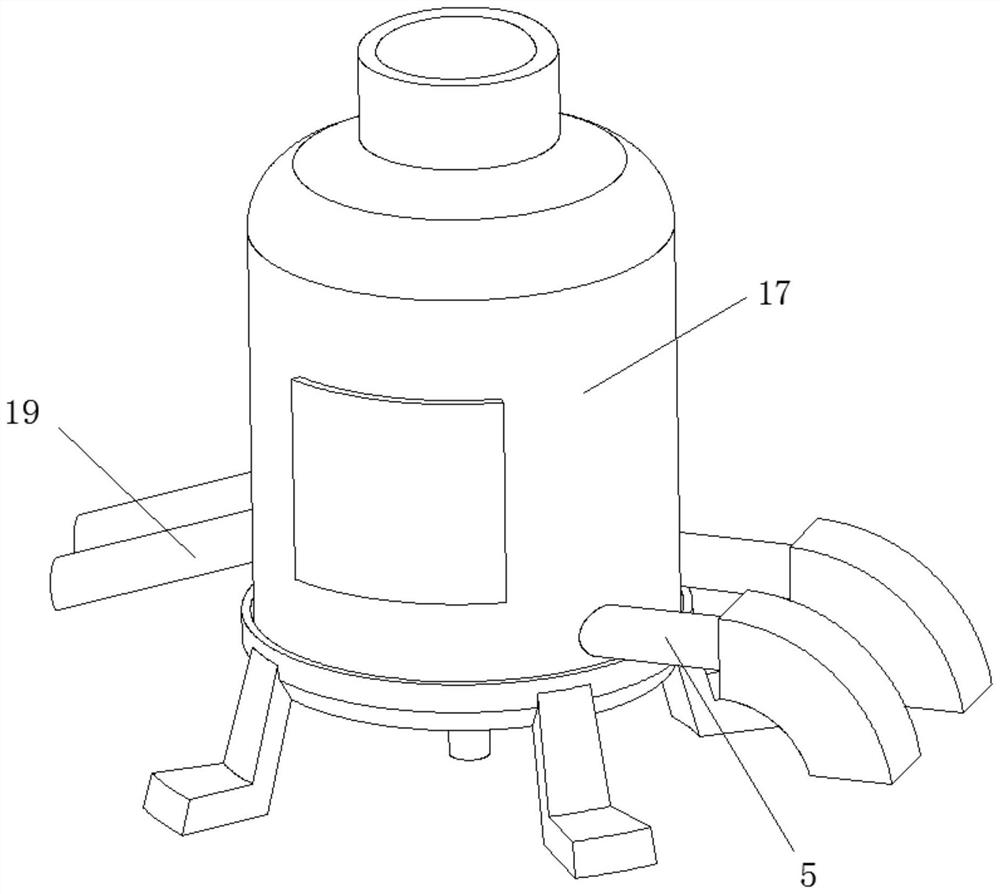

[0055] Embodiment 2, an extraction tower used in a hydrogen peroxide preparation process, the top of the extraction tower 1 is fixedly connected with a mixed solution inlet 2, and the tower section of the inner cavity of the extraction tower 1 is sleeved with a dispersion injection cone plate 4, the inner surface of the dispersing injection cone plate 4 is fixedly connected with a filter screen rod 3, the bottom of the extraction tower 1 is fixedly connected with a preparation tank shell 17, and the bottom of the outer surface of the preparation tank shell 17 is fixedly connected with a Extraction outlet 5, the middle of the outer surface of the preparation tank shell 17 is fixedly connected with a raffinate outlet 19, the bottom of the inner cavity of the preparation tank shell 17 is provided with a cover plate 8, the cover plate The outer surface of 8 is fixedly connected with an air transmission cover 9, and the outer surface of the air transmission cover 9 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com