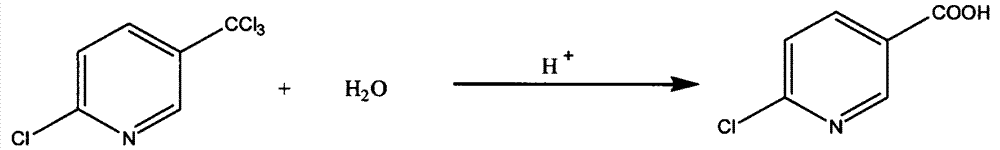

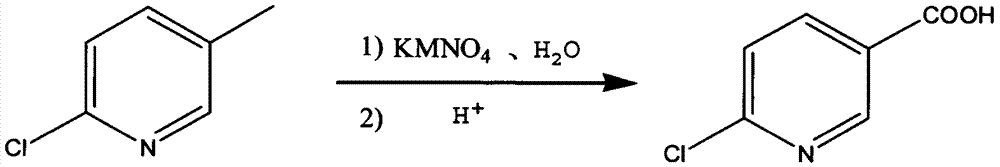

Preparation method of 6-chloronicotinic acid

A technology of chloronicotinic acid and cobalt acetate, which is applied in the field of catalytic oxidation to prepare 6-chloronicotinic acid, can solve the problems of three wastes treatment, and achieve the effects of low cost, good product quality and yield, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In a 1000mL flask, add 450g of chlorobenzene, 100g of 2-chloro-5-methylpyridine, and 3g of cobalt acetate catalyst under stirring, heat the system up to 80°C, and feed oxygen, the oxygen flow rate is controlled at 0.4L / min, React under these conditions for 4 hours. After the reaction, the system was cooled to room temperature, filtered, and dried to obtain 119 g of a mixture of 6-chloronicotinic acid and cobalt acetate.

[0037] Put the above-mentioned mixed crude product in a 1000mL flask, add 600g of recrystallization solvent methanol, stir and raise the temperature to reflux, wait until the crude product of 6-chloronicotinic acid is completely dissolved, and keep it warm for 5min, the system is slowly cooled to 5°C, white crystals are precipitated, and the temperature is maintained at this After continuing to stir at internal temperature for 1 hour, filter, wash the filter cake once with a small amount of cooled methanol, and dry the obtained tidal product at 80°C fo...

Embodiment 2

[0040] In a 1000mL flask, add 600g of chlorobenzene, 100g of 2-chloro-5-picoline, and 1g of catalyst cobalt acetate under stirring, heat the system up to 70°C, and feed oxygen. The oxygen flow rate is controlled at 1.0L / min. Under these conditions, the reaction was carried out for 5 hours. After the reaction, the system was cooled to room temperature, filtered, and dried to obtain 107 g of a mixture of 6-chloronicotinic acid and cobalt acetate.

[0041] Put the above-mentioned mixed crude product in a 1000mL flask, add 550g of recrystallization solvent methanol, stir and raise the temperature to reflux, wait until the crude product of 6-chloronicotinic acid is completely dissolved, keep warm for 3min, the system cools down to 7°C, white crystals are precipitated, and the temperature is maintained at this temperature. Continue to stir at high temperature for 70 minutes, then filter off the crystallization mother liquor, and dry the obtained tidal product in an oven at 75° C. fo...

Embodiment 3

[0044] In a 1000mL flask, add 400g of chlorobenzene, 100g of 2-chloro-5-picoline, and 10g of catalyst cobalt acetate under stirring, heat the system up to 100°C, and feed in oxygen. The oxygen flow rate is controlled at 0.4L / min. Under these conditions, the reaction was carried out for 7 hours. After the reaction, the system was cooled to room temperature and filtered, and dried to obtain a mixture of 114g 6-chloronicotinic acid and cobalt acetate

[0045] Put the above-mentioned mixed crude product in a 1000mL flask, add 570g of recrystallization solvent methanol, stir and raise the temperature to reflux, wait until the crude 6-chloronicotinic acid is completely dissolved, keep warm for 7min, cool the system to 3°C, white crystals are precipitated, keep Continue to stir at high temperature for 90 minutes, then filter off the crystallization mother liquor, and dry the obtained tidal product in an oven at 90°C for 3 hours to obtain 95.2 g of genuine 6-chloronicotinic acid, with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com