Patents

Literature

53results about How to "To achieve a closed effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for janus structure based rapid hemostatic agent having directional propulsion function

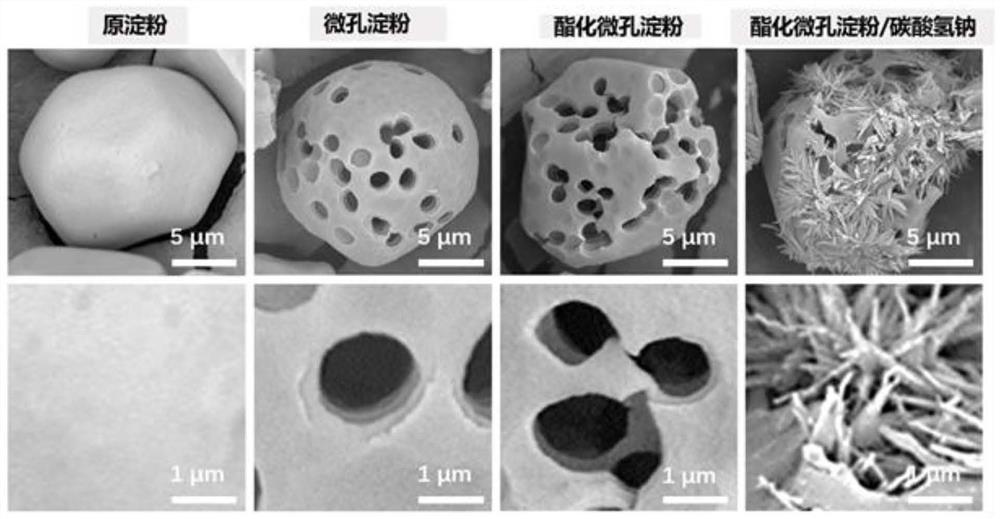

ActiveCN111135339AEffective hemostasisGood biocompatibilitySurgical adhesivesPharmaceutical delivery mechanismJanus particlesDeep wounds

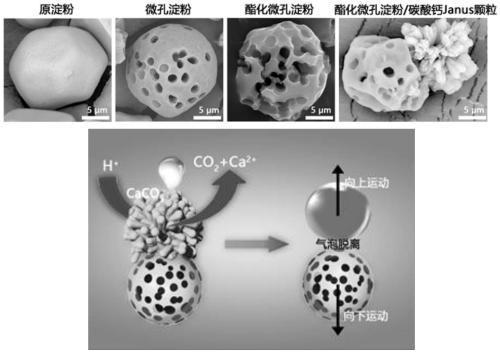

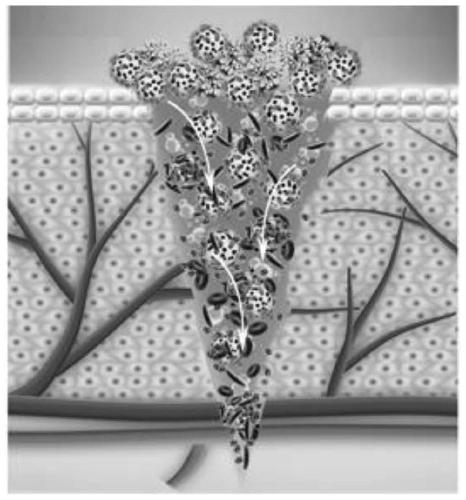

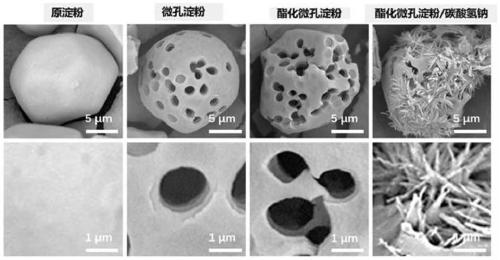

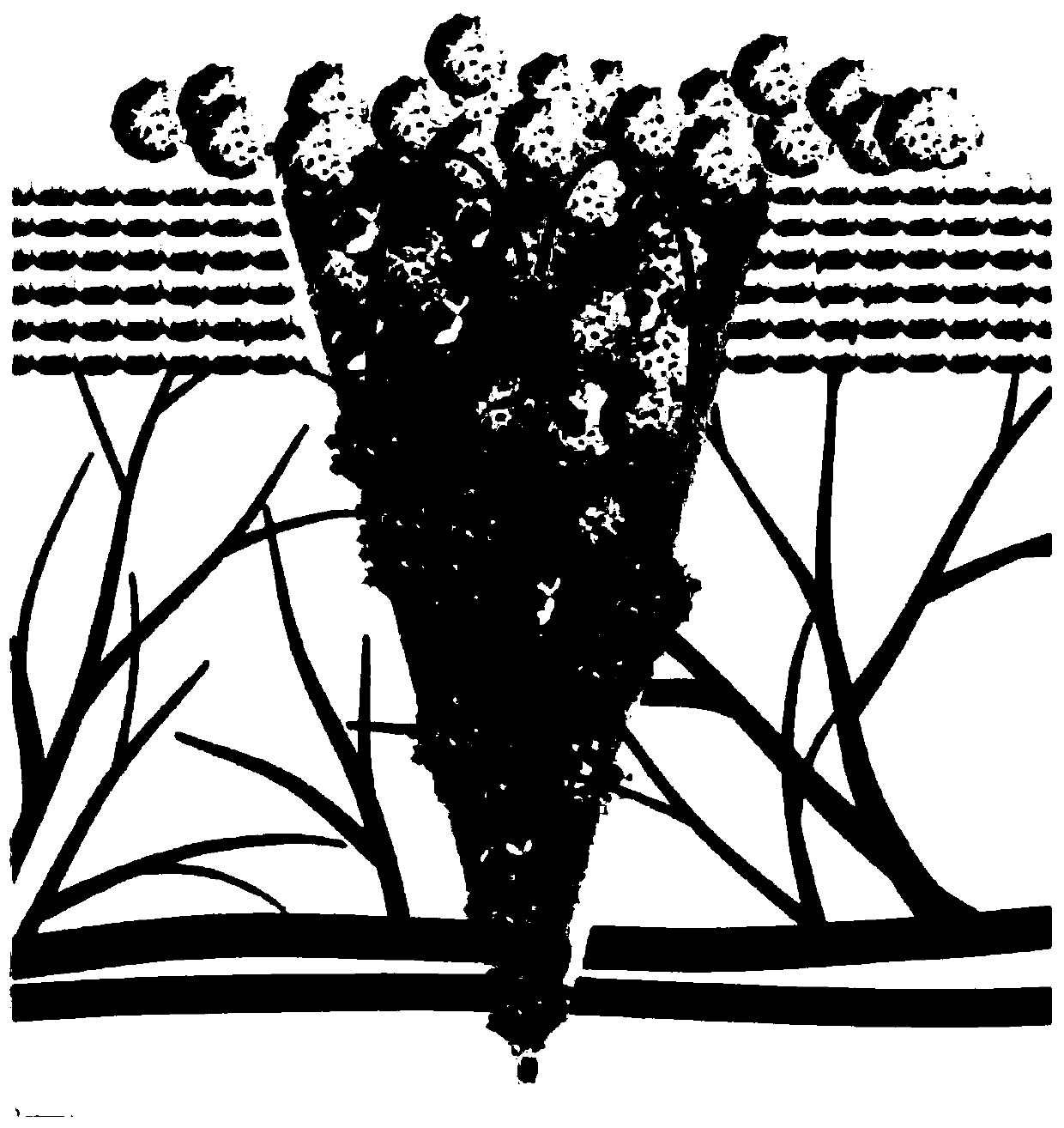

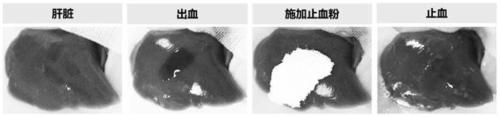

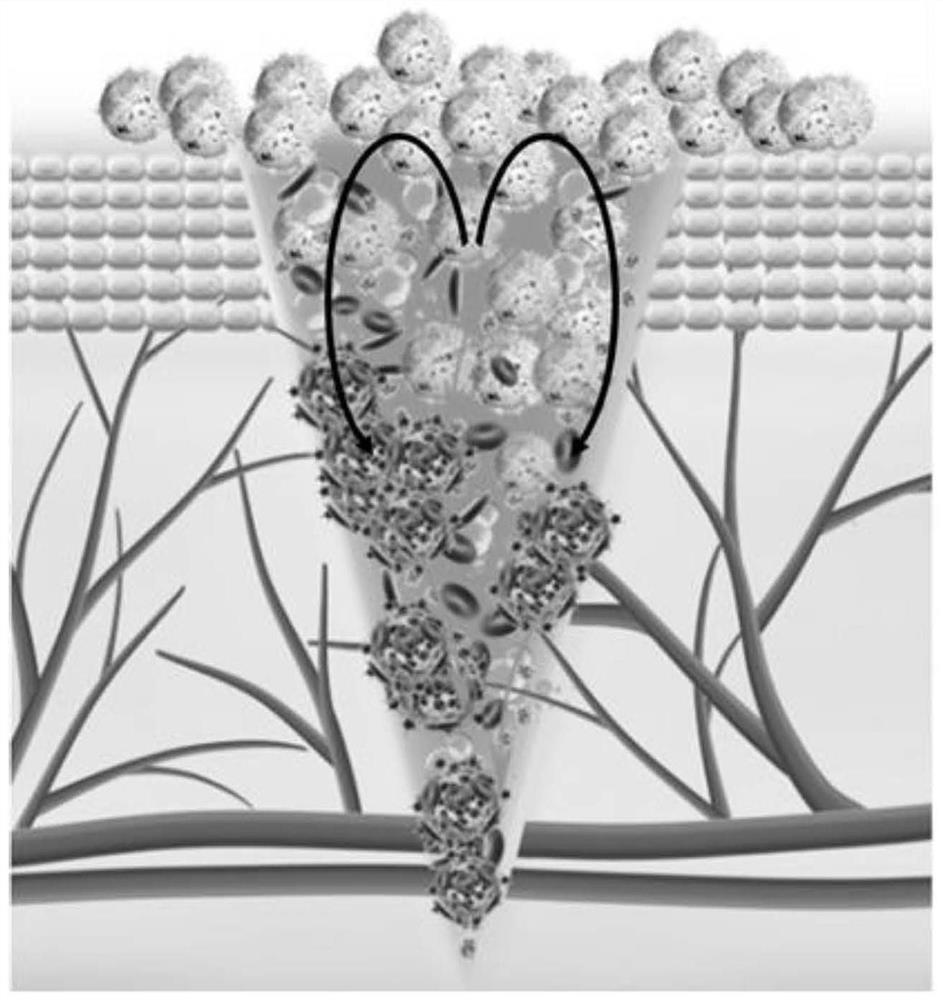

For defects that existing hemostasis research and products cannot intelligently perform self-propelling or cannot be driven to forward deep in the wound under the action of external field force, the invention provides a preparation method for a janus structure based rapid hemostatic agent having a directional propulsion function. The preparation method includes performing esterification on microporous starch to unidirectionally grow calcium carbonate particles so as to obtain esterified microporous starch / calcium carbonate Janus particles; fixedly assembling thrombin on the surfaces of the esterified microporous starch / calcium carbonate Janus particles to obtain esterified microporous starch / calcium carbonate Janus particles assembled with the thrombin; mixing the esterified microporous starch / calcium carbonate Janus particles assembled with the thrombin and protonated tranexamic acid powder so as to obtain the janus structure based rapid hemostatic agent having a directional propulsion function. Through the formation of the biphasic heterogeneous Janus structure, the unidirectional and intelligent self-propulsion of hemostatic starch can be realized by cooperating with the protonated tranexamic acid, so that rapid three-dimensional hemostasis on deep wounds, penetrating wounds and irregular wounds such as aortic / venous rupture can be realized.

Owner:SOUTHWEST UNIVERSITY

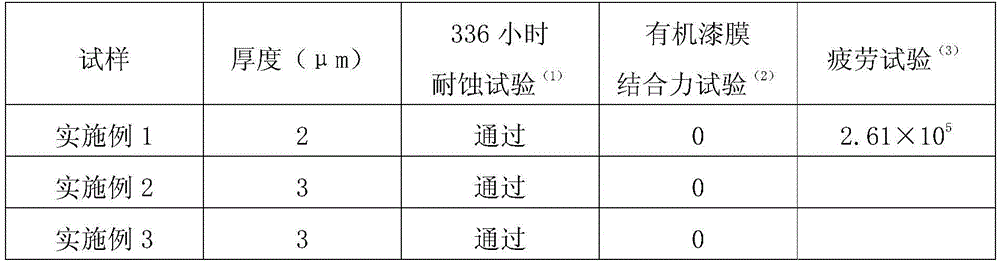

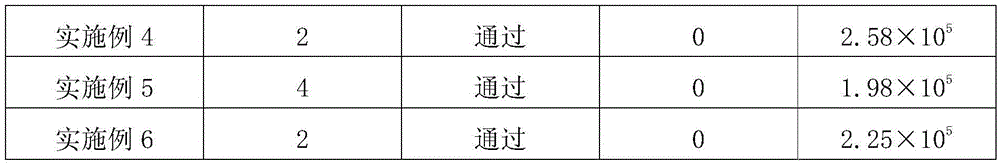

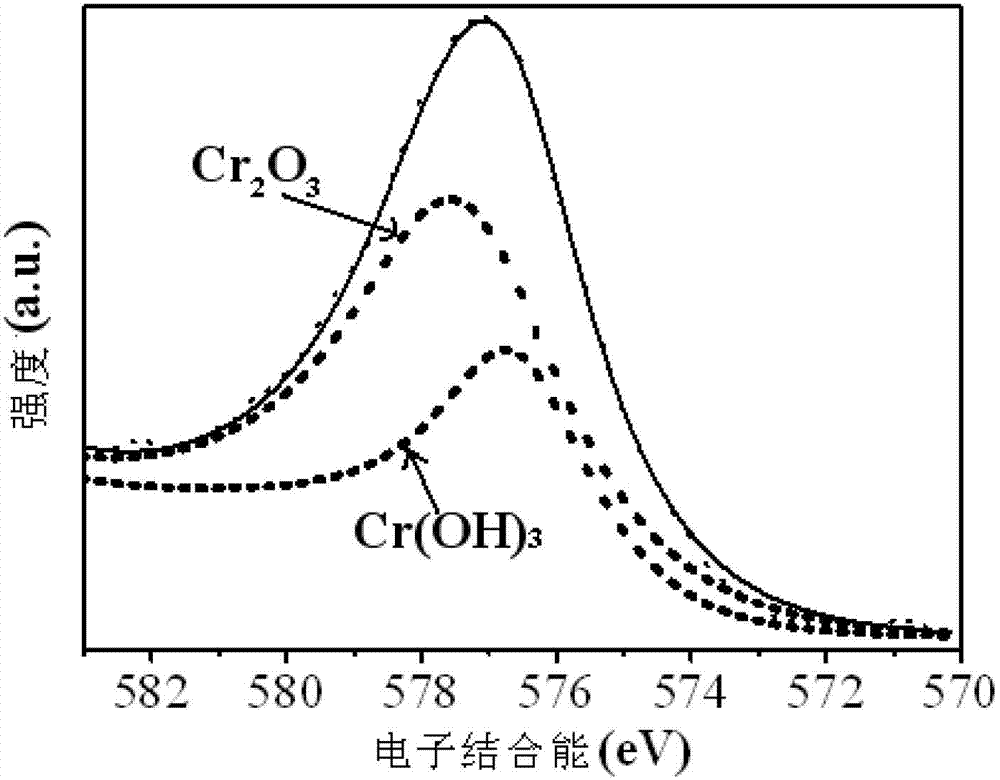

Anodizing method improving protection performance of aluminum and aluminum alloy

ActiveCN105463549AImprove immersion effectNo pollution in the processAnodisationAviationChromium free

The invention provides an anodizing method improving protection performance of aluminum and aluminum alloy. An anodizing solution is formed by mixing at least one of inorganic salt of sulfuric acid, sodium borate, malic acid and cerium and water according to the proportion. A voltage control manner is adopted in anodizing for anodizing treatment on aluminum or aluminum alloy materials. An anodized film layer prepared through the method is good in corrosion resistance, good in combining performance with an organic paint film and low in fatigue performance on a base body and has the beneficial effects of being simple in technology, stable in performance, high in film forming efficiency and small in environment pollution. Organic-inorganic hybrid chromium-free closing method is selected after anodizing, chromium and other poisonous and harmful substances are not contained in confining liquid completely, and waste liquid discharging does not exist in the sealing process. The sealed anodized film layer is good in corrosion resistance, and the combining force of an original anodized film layer paint film is not influenced. The anodizing method and the sealing method can be used for replacing traditional chromic acid anodizing, sulfuric acid anodizing and dichromate sealing technologies and is applied to protection of aluminum and aluminum material surfaces of various industries such as aviation.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS +1

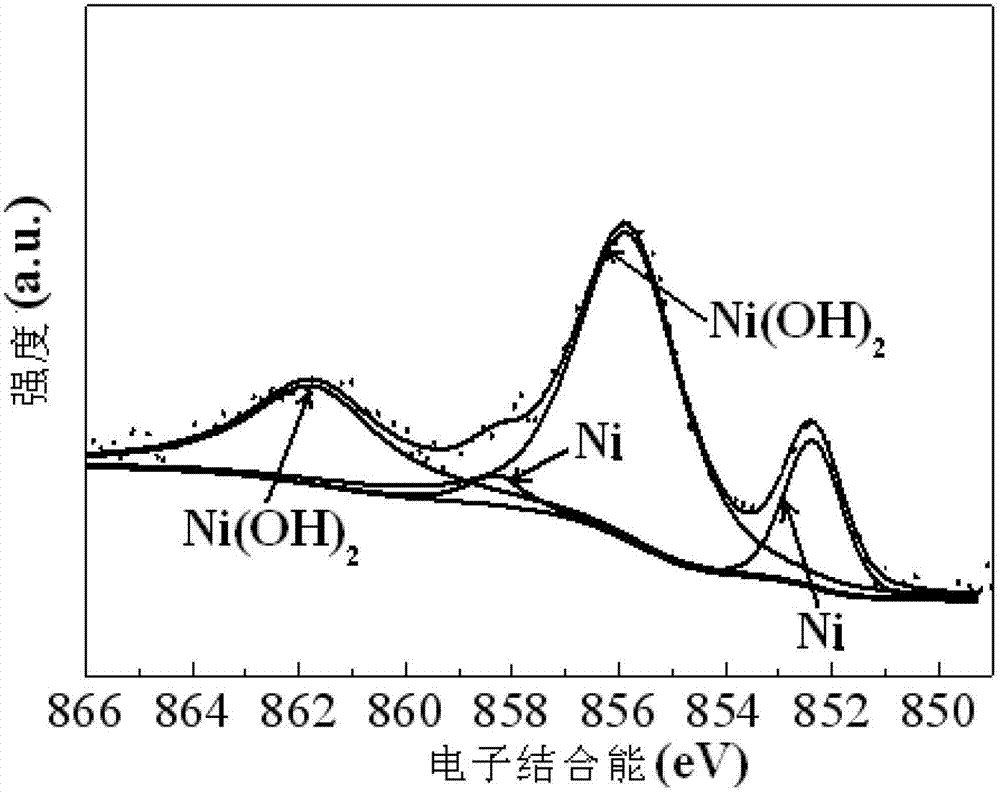

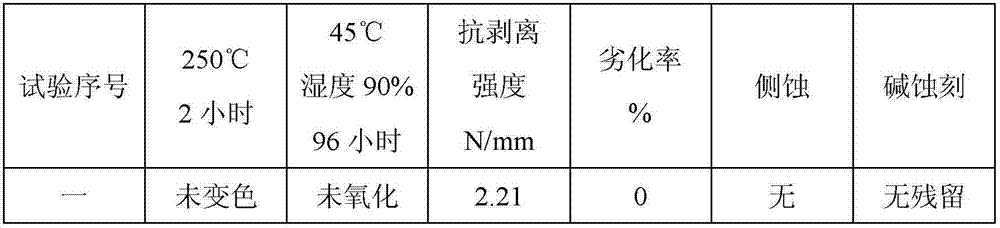

Method for displacement plating of Ni-S alloy barrier layer on copper foil, and chemical passivation method of barrier layer

InactiveCN102732862ARealize the displacement reactionSpontaneous and rapid depositionLiquid/solution decomposition chemical coatingHeat resistanceCopper foil

The invention relates to a method for displacement plating of a Ni-S alloy barrier layer on a copper foil, and a chemical passivation method of the barrier layer, in particular to a preparation method of the barrier layer on the copper foil, and a passivation method of the barrier layer, aiming at solving the technical problems that the existing preparation method of the barrier layer on the copper foil is complicated, the barrier layer is poor in ion migration resistance, heat resistance, corrosion resistance and high-temperature antioxidation and low in peel strength. The method for displacement plating of the Ni-S alloy barrier layer on the copper foil comprised the steps of: 1. preparing Ni displacement plating solution; 2. pretreating the copper foil; and 3. soaking the copper foil into the Ni displacement plating solution to obtain the Ni-S alloy barrier layer plated on the copper foil. The chemical passivation method comprises the step of soaking the copper foil plated with the Ni-S alloy barrier layer into passivating solution. In Ni-S alloy, the atomic percent of S is 0.1-30%, and the thickness of a passivation layer is 5-30nm. The methods provided by the invention can be used for treating a printed circuit board (PCB).

Owner:HARBIN INST OF TECH

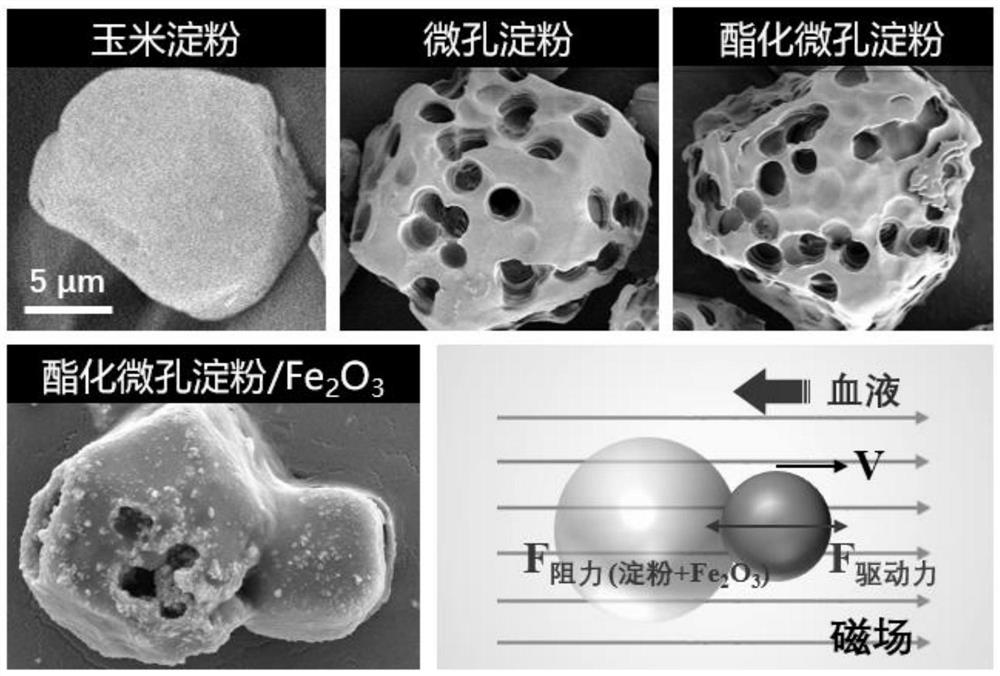

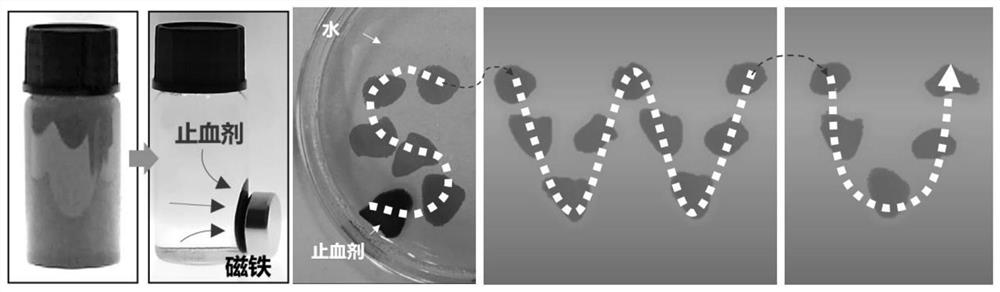

Preparation method of janus structure hemostatic with directional driving function

ActiveCN112891612AEffective hemostasisGood biocompatibilitySurgical adhesivesPharmaceutical delivery mechanismSodium bicarbonateJanus particles

The invention provides a preparation method of a janus structure hemostatic with a directional driving function, aiming at the defects that a bubble-driven powder hemostatic in the prior art has a better effect on deep, penetrating and aortic / venous rupture wounds, but cannot penetrate into bleeding points in deep parts of the wounds to effectively block the irregular or curved wounds, the hemostatic effect is not ideal, and rapid hemostasis cannot be realized. The preparation method comprises the following steps of: carrying out unidirectional self-aggregation on magnetic nano-iron oxide by utilizing esterified microporous starch to obtain esterified microporous starch / nano-iron oxide janus particles; carrying out immobilized assembly on thrombin on the surfaces of the esterified microporous starch / nano-iron oxide Janus particles, and coating the surfaces with sodium bicarbonate to obtain sodium bicarbonate coated and thrombin assembled esterified microporous starch / nano-iron oxide Janus particles; and then mixing the sodium bicarbonate coated and thrombin assembled esterified microporous starch / nano-iron oxide Janus particles with protonated acidic salt powder to obtain the janus structure hemostatic with the directional driving function.

Owner:SOUTHWEST UNIVERSITY

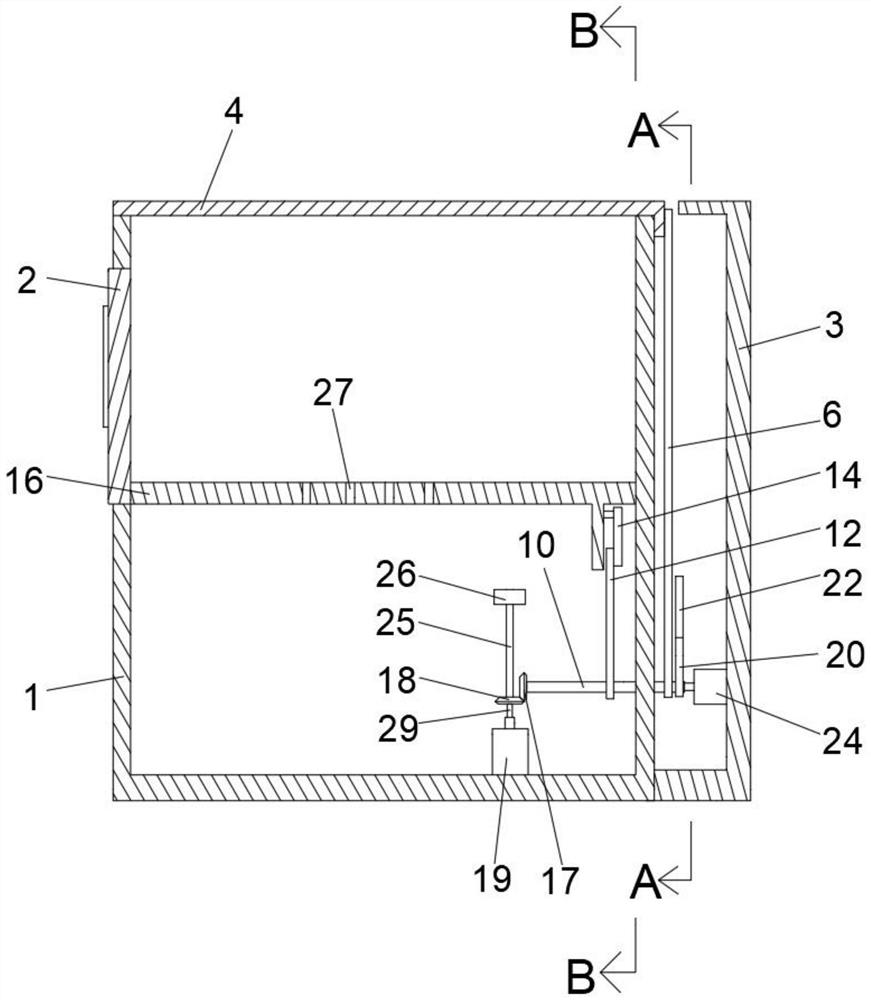

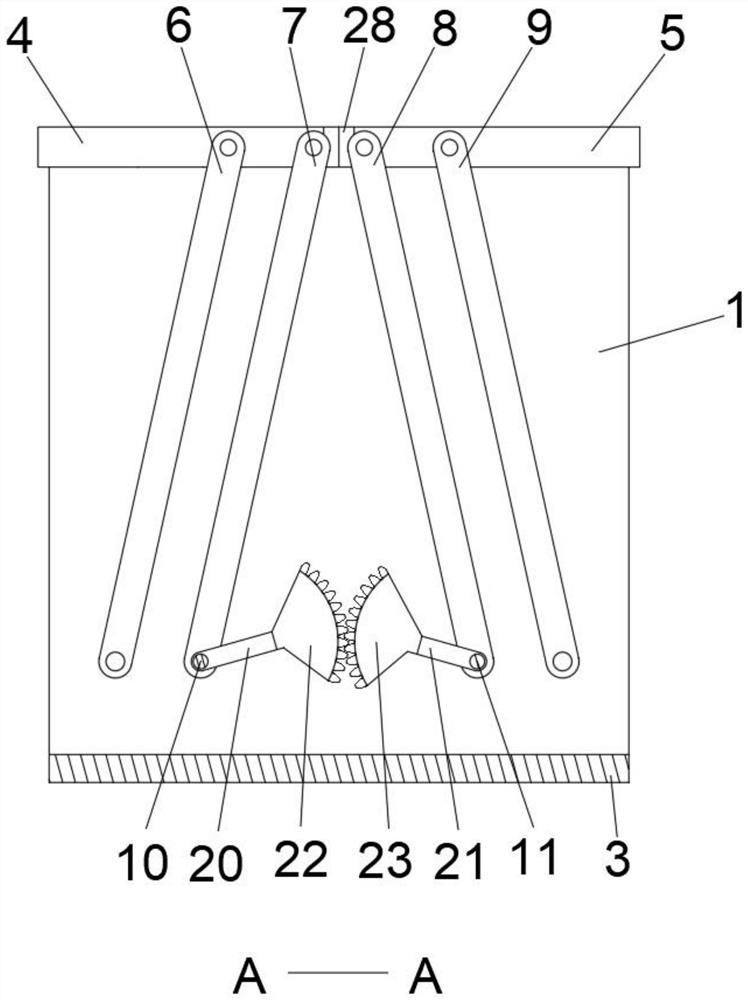

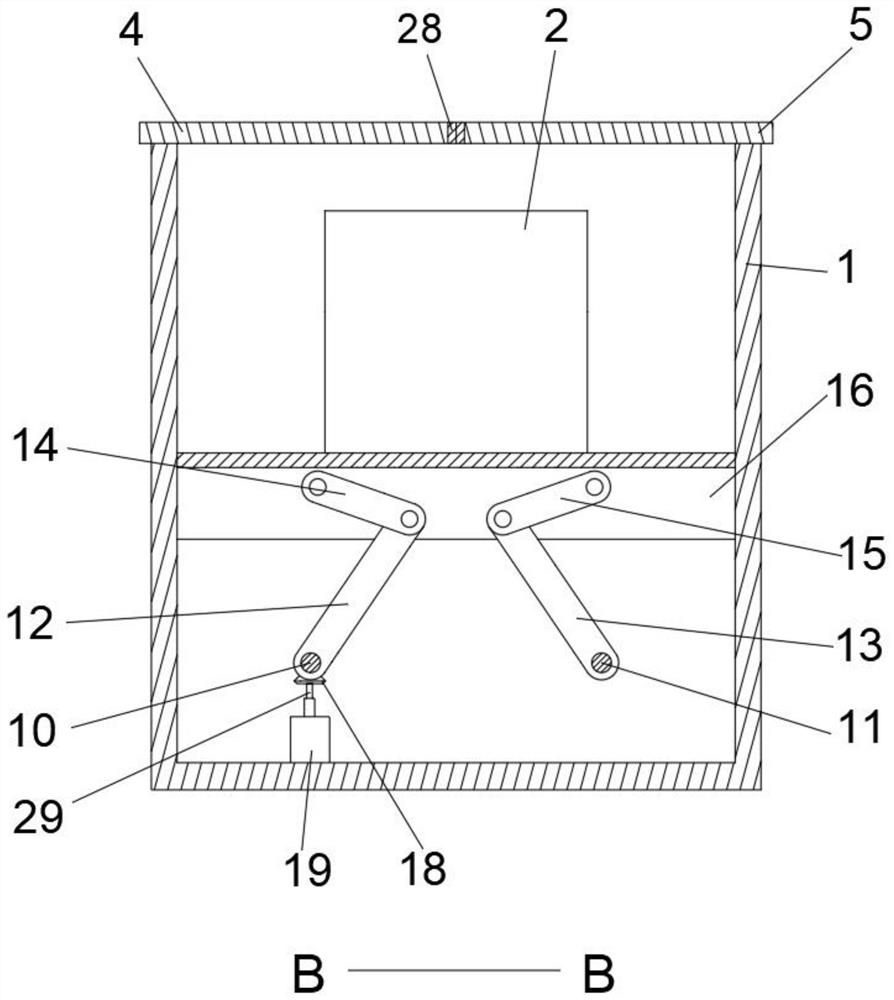

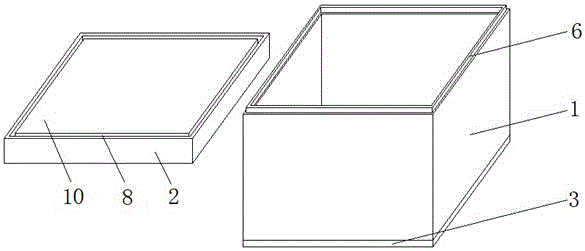

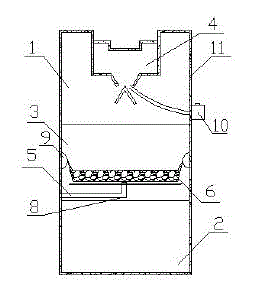

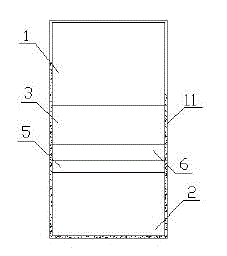

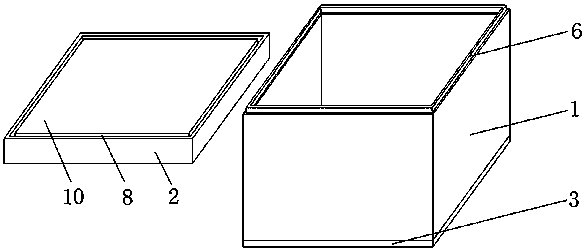

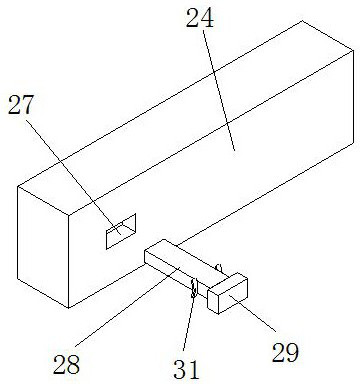

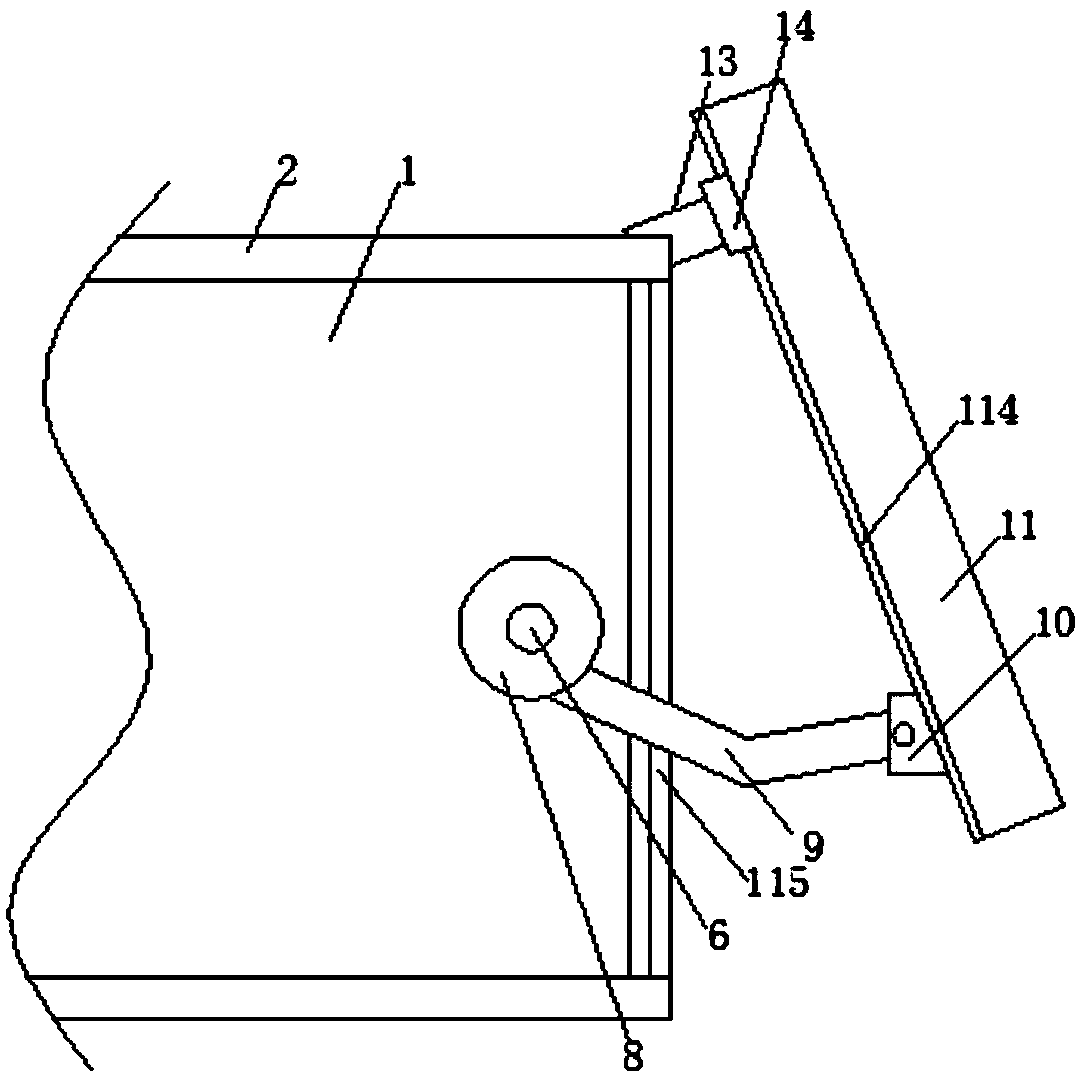

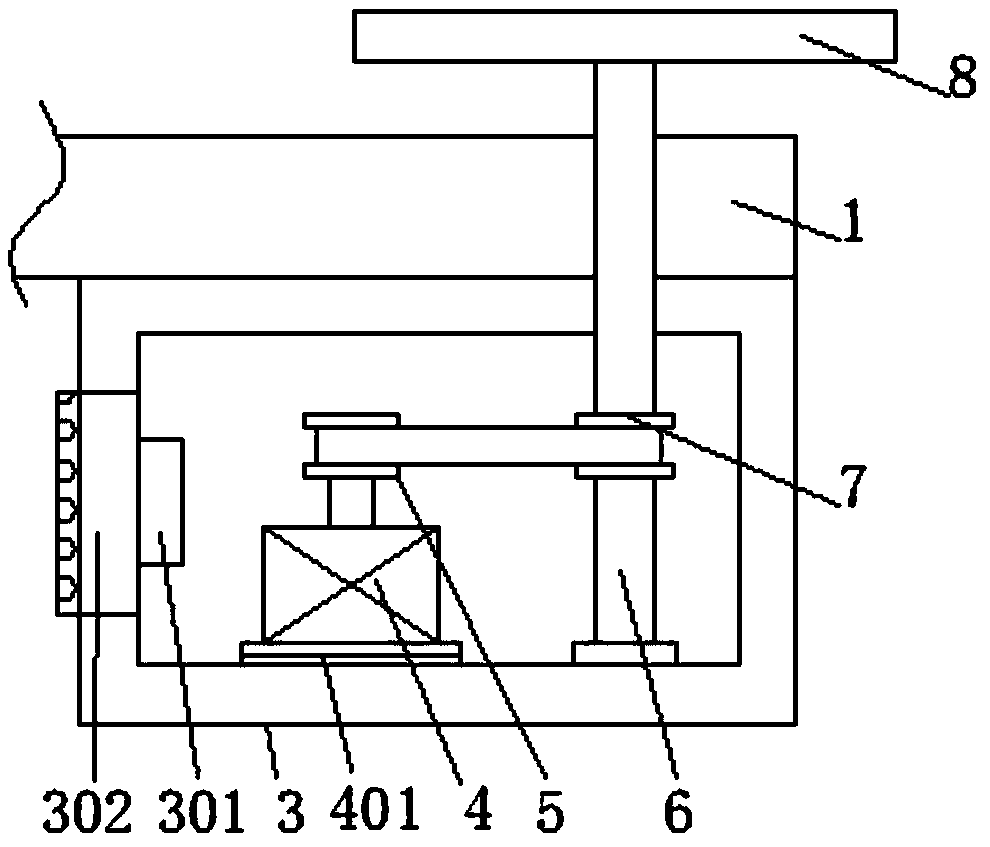

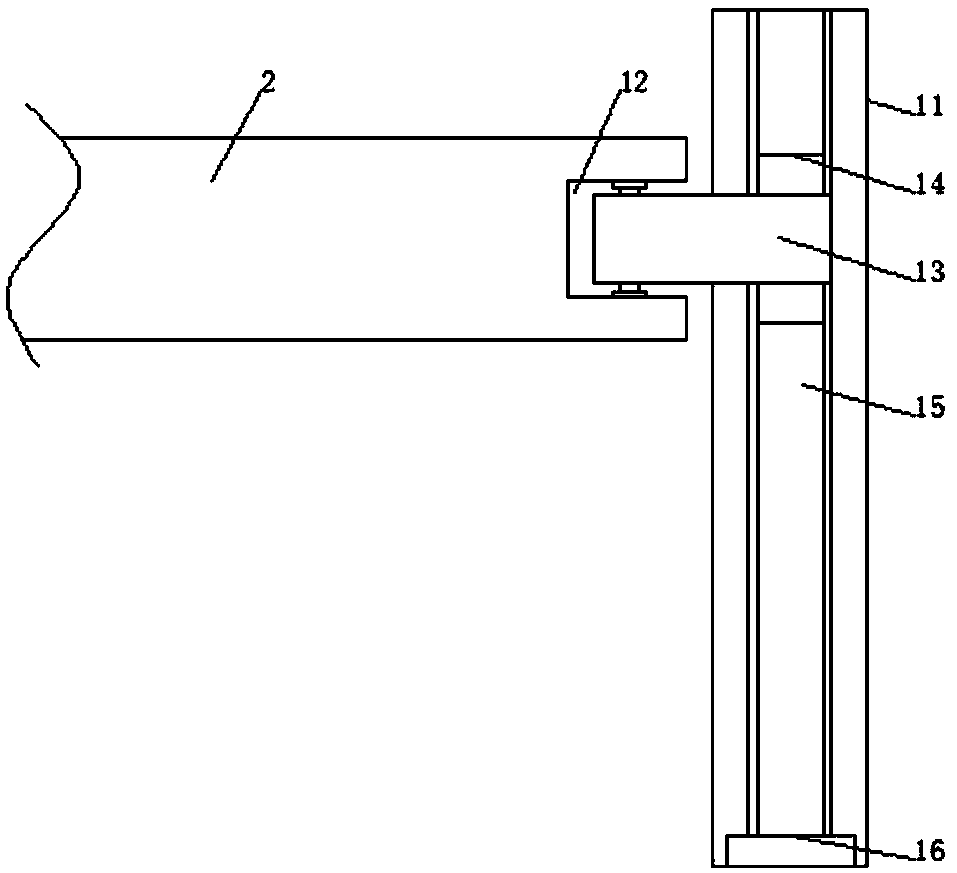

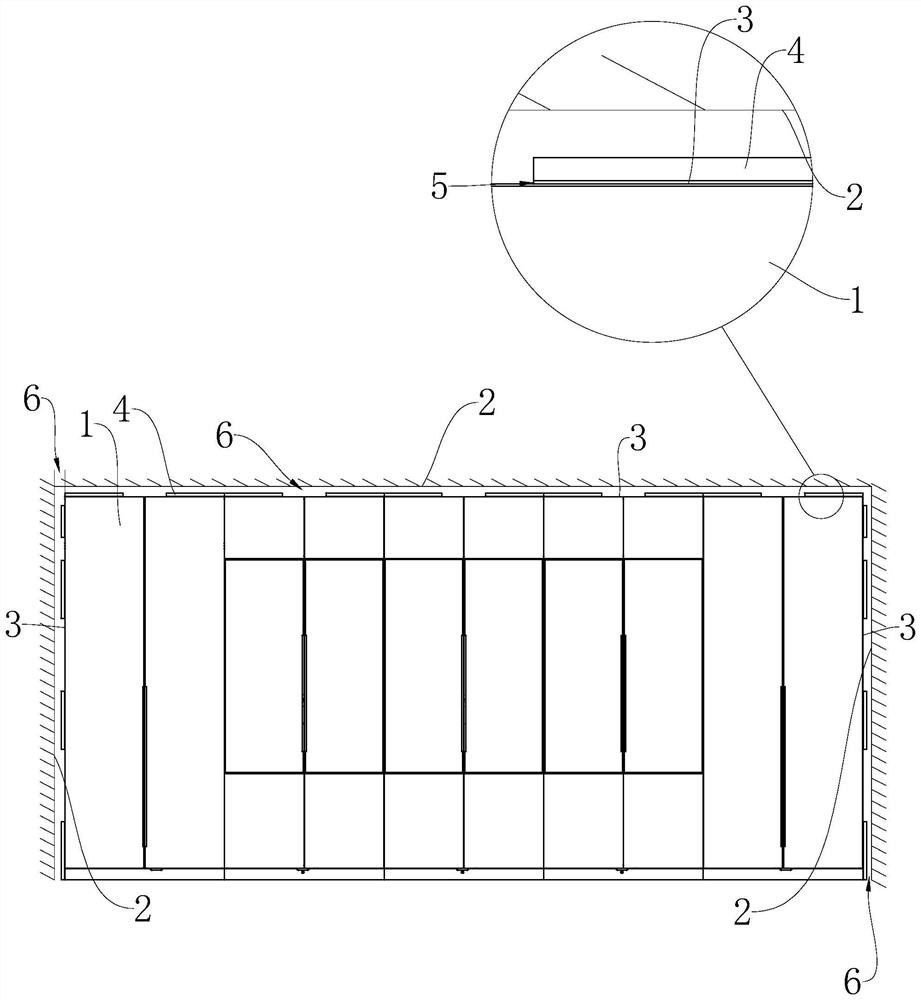

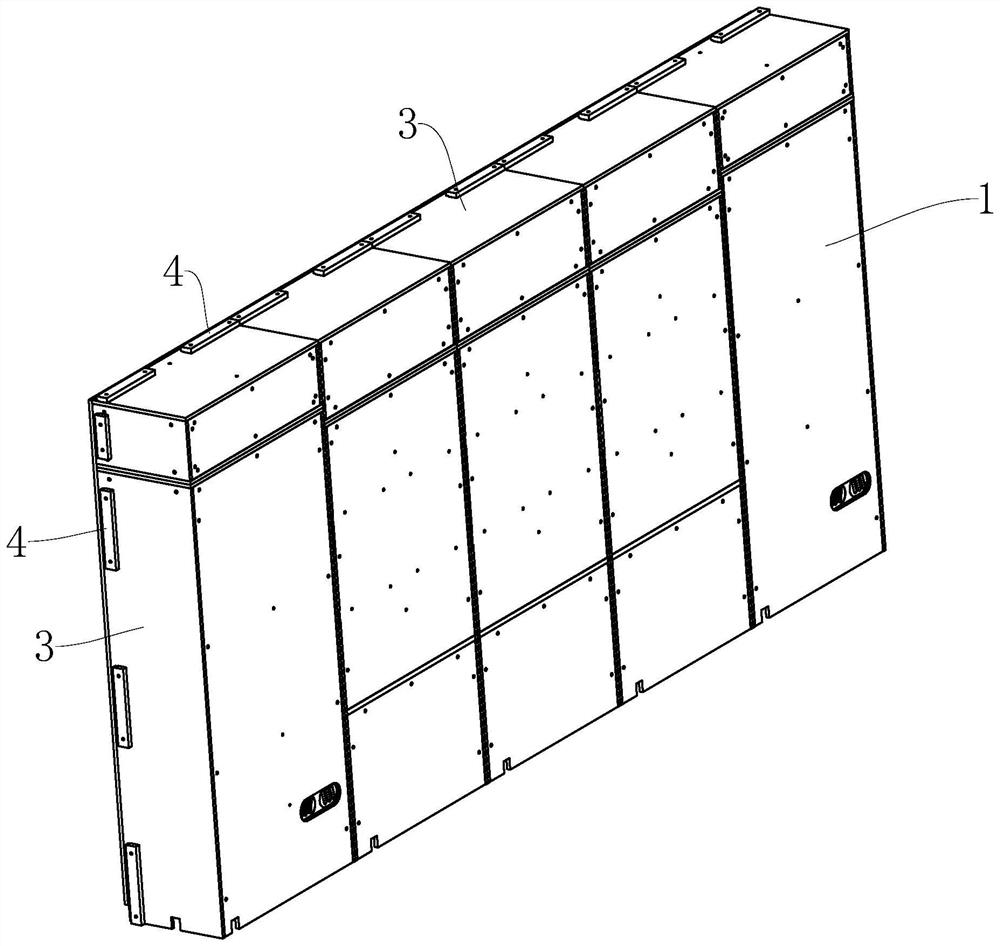

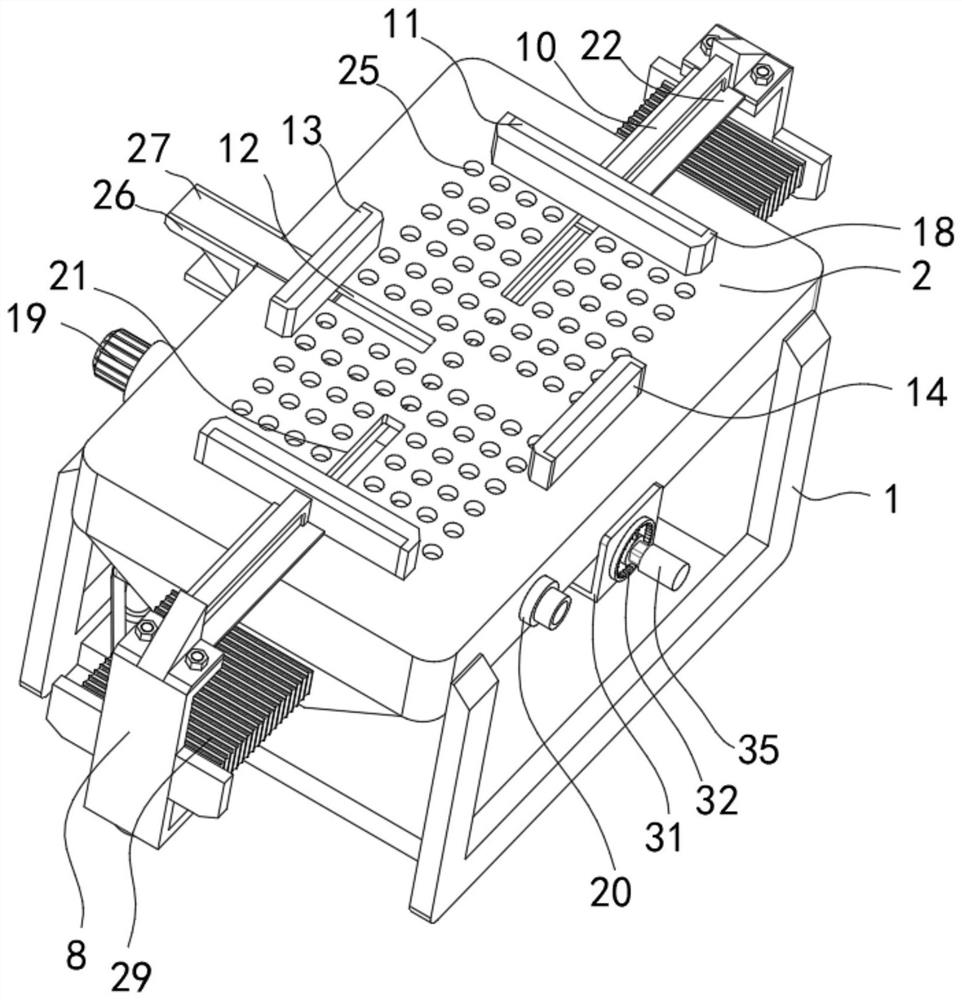

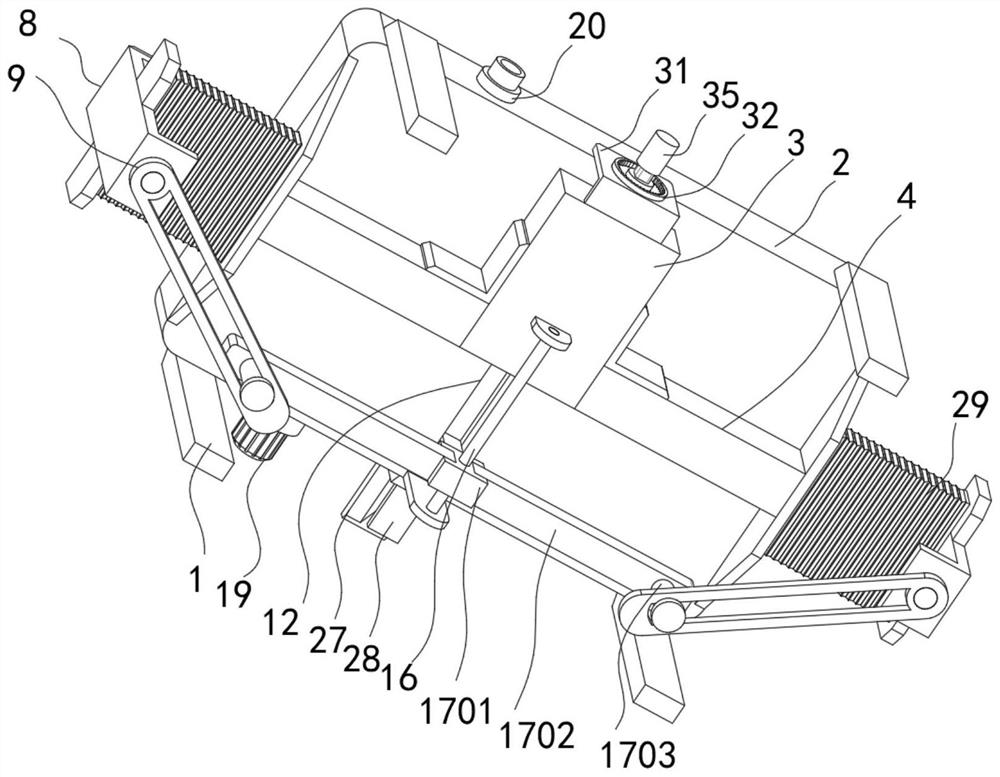

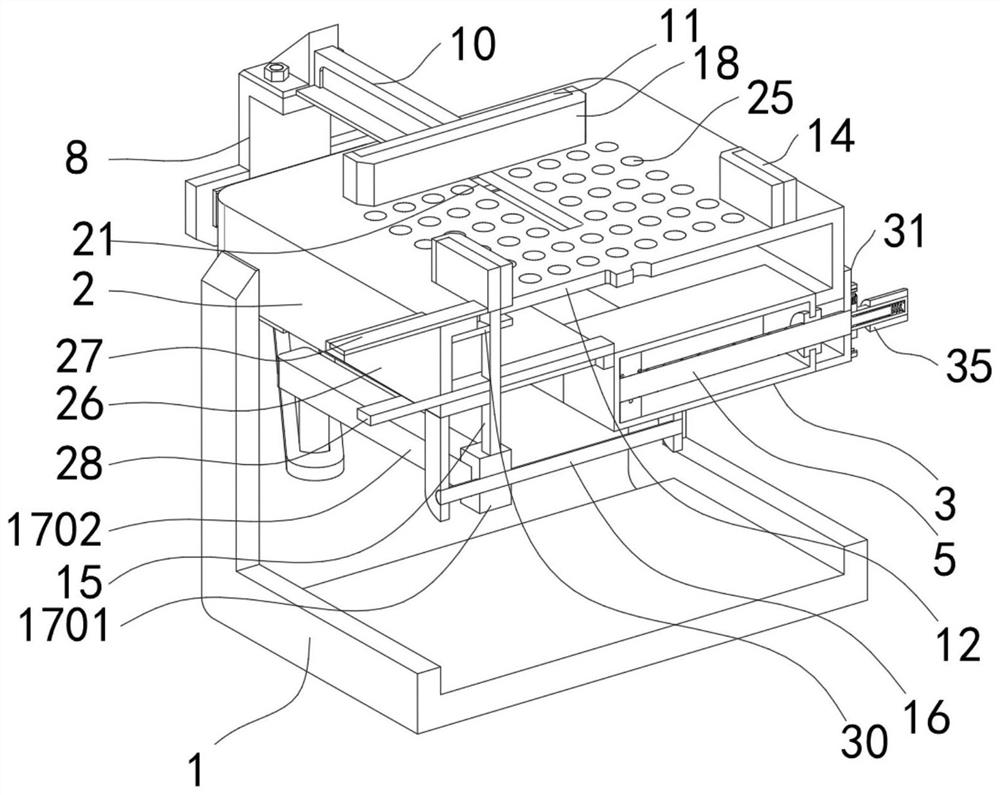

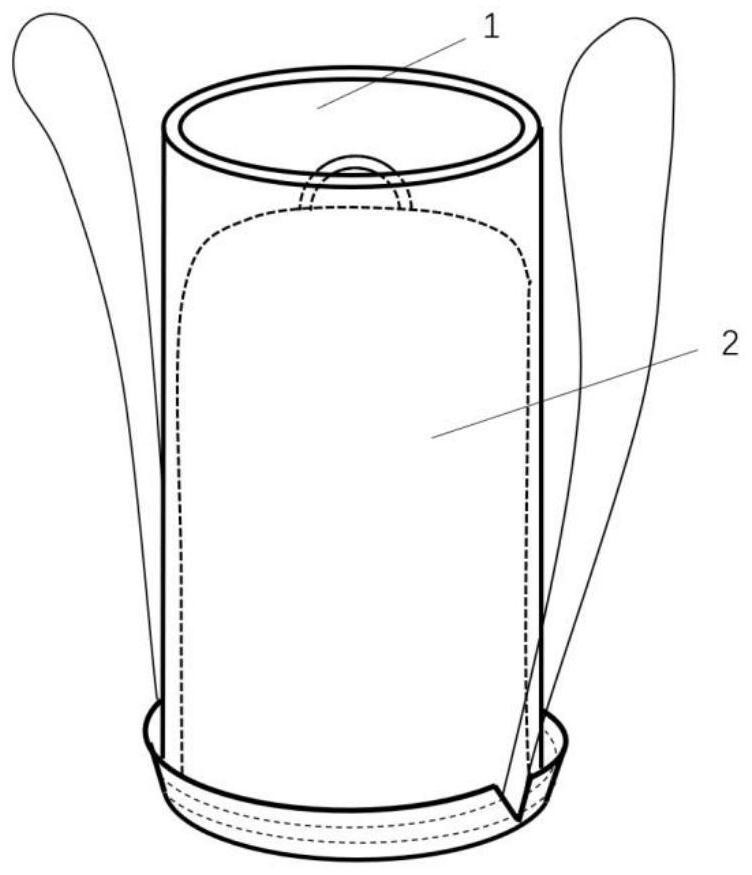

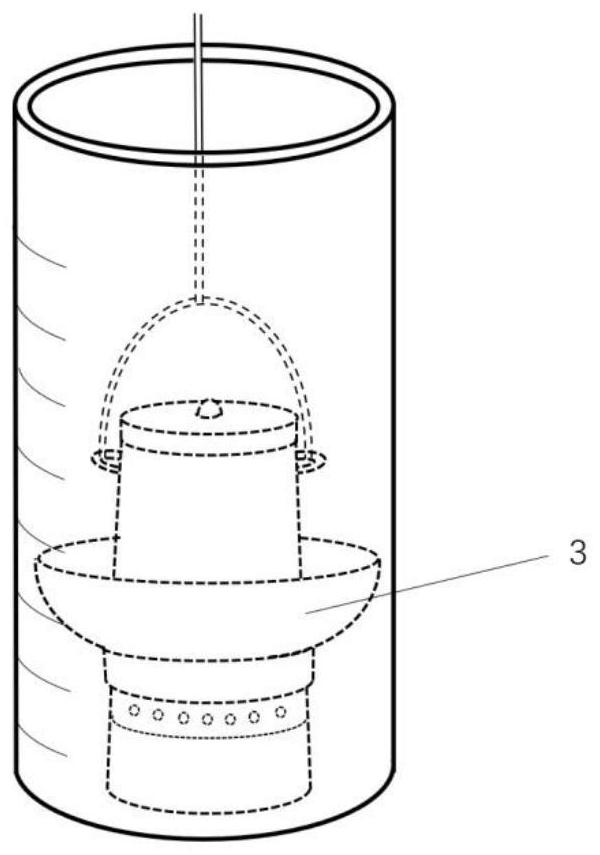

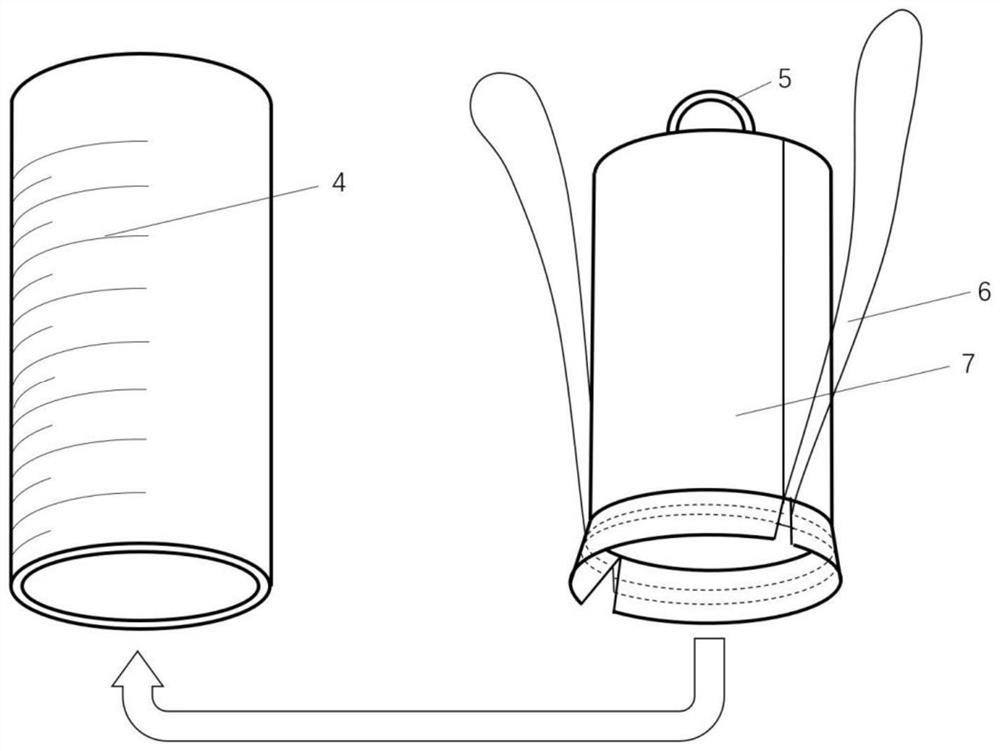

Safety box

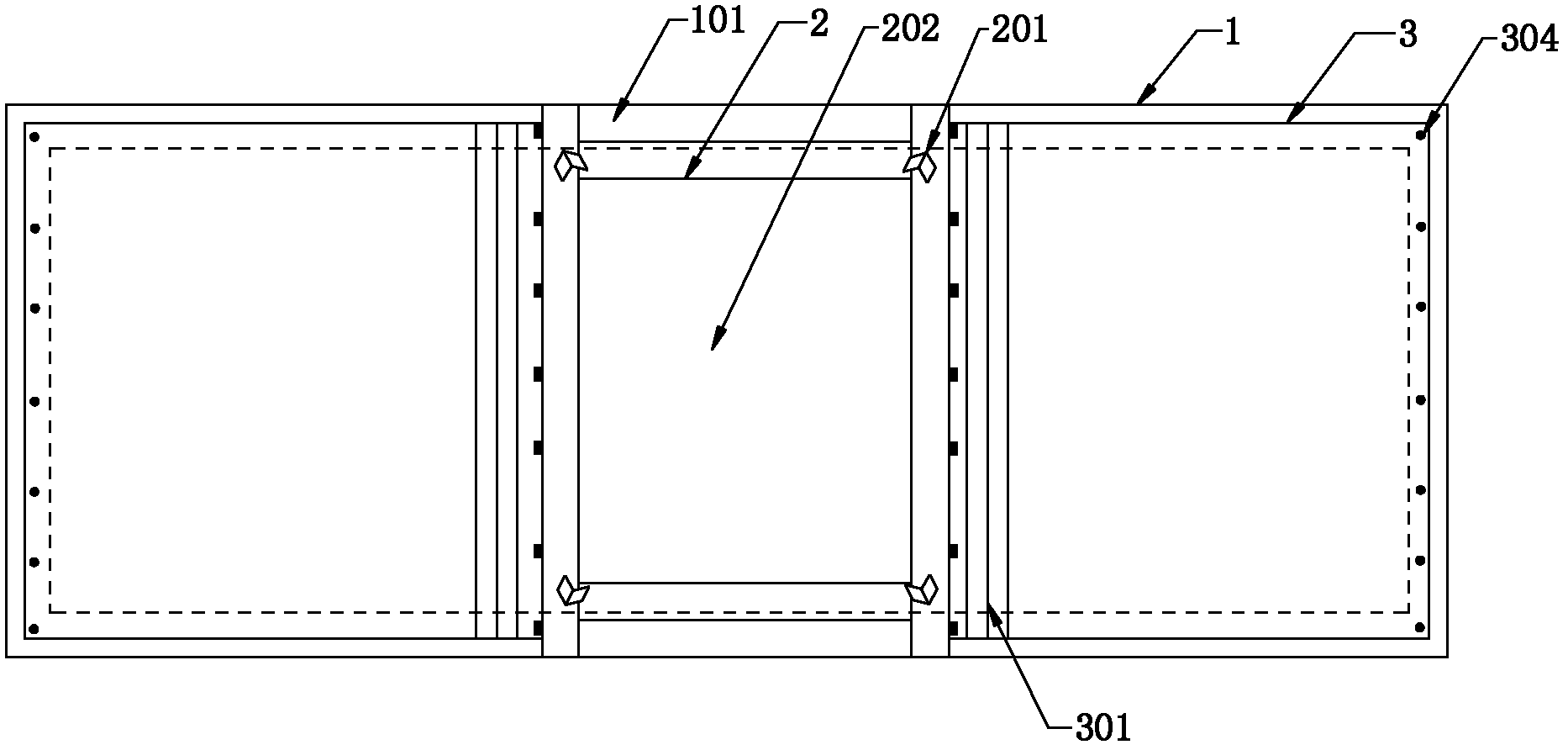

InactiveCN112282568ATo achieve a closed effectEasy to useDispersed particle separationMachines/enginesStructural engineeringMechanical engineering

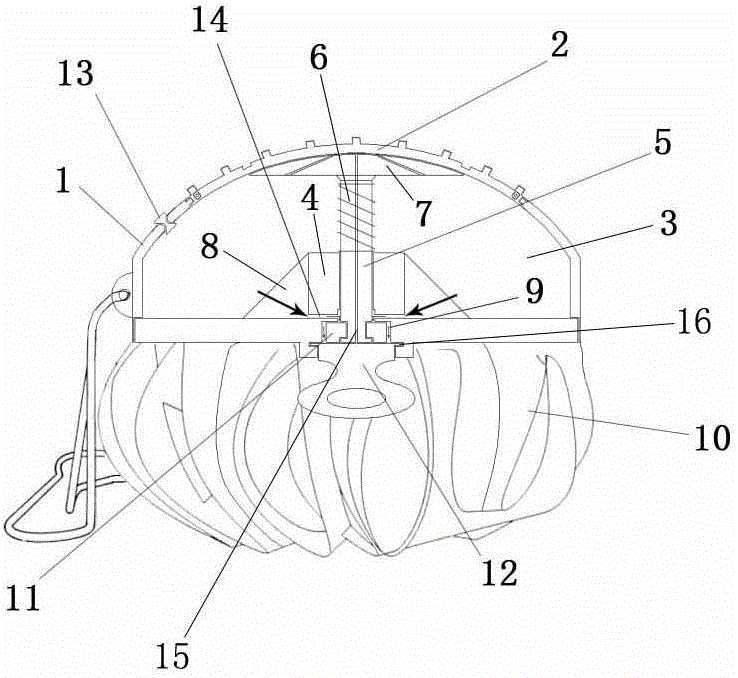

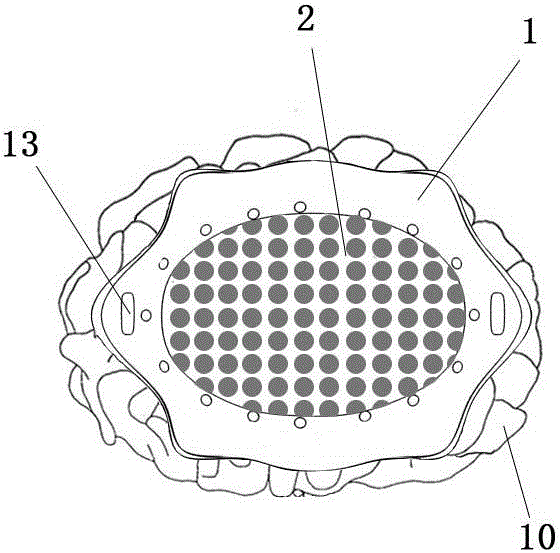

The invention discloses a safety box, and relates to the technical field of safety boxes. The safety box comprises a box body and a box door, wherein an isolation plate is fixedly connected to the surface of the box body; a left cover plate and a right cover plate abut again the upper surface of the box body; a hinge rod I and a hinge rod II are hinged to one side, far away from the box door, of the left cover plate; a hinge rod III and a hinge rod IV are hinged to the side, away from the box door, of the right cover plate; the bottom ends of the hinge rod I and the hinge rod IV are hinged tothe surface of the box body separately; a rotating shaft I is fixedly connected to the inner wall of the bottom end of the hinge rod II; and a rotating shaft II is fixedly connected to the inner wallof the bottom end of the hinge rod III. According to the invention, through mutual cooperation of the structures, the safety box is suitable for being used in different environments, has different opening modes, does not need manual operation of operators, is rapid and convenient to use, has a dehumidification function and an automatic endurance effect, and solves the problems that a traditional safety box is inconvenient to use and cannot meet the use requirements under different conditions.

Owner:江西德沃箱柜制造有限公司

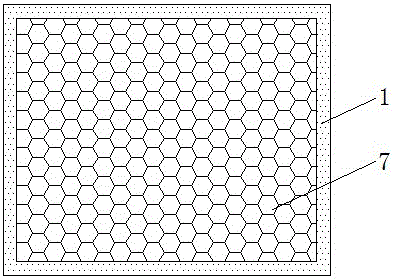

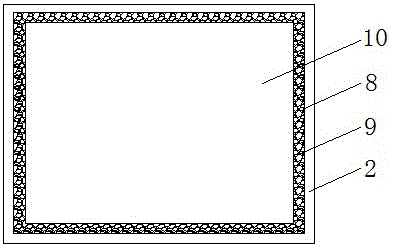

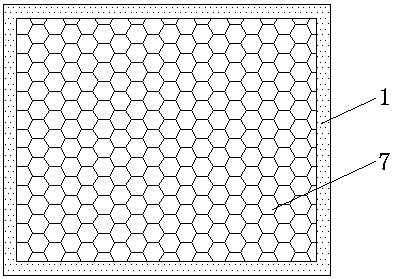

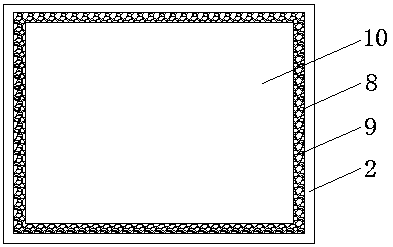

Novel sealing box

The invention discloses a novel sealing box. The novel sealing box comprises a box body and a box cover, wherein a damping plate is arranged at the bottom of the box body; a damping ball is arranged inside the damping plate; the damping ball is separated by a baffle; a convex plate is fixedly mounted at the edge of the top of the box body; the box body is formed by four sealing plates in a surrounding way; insulated cotton is arranged inside each sealing plate; a rubber plate is arranged on the inner surface of the box cover; a groove is formed between the rubber plate and the box cover; a silicone pad is arranged at the bottom of the groove. The novel sealing box can be sealed into a whole body through the convex plate and the groove formed in the box body and the box cover, achieves the effect of sealing, achieves the purpose of sealing the box body through an air bag, a supporting column and a supporting plate arranged inside the rubber plate, achieves the purpose of keeping constant temperature of the sealing box through the insulated cotton arranged in the sealing plates, and achieves the effect of protecting objects through the damping plate.

Owner:JIANGSU YONGSHANG ENERGY TECH

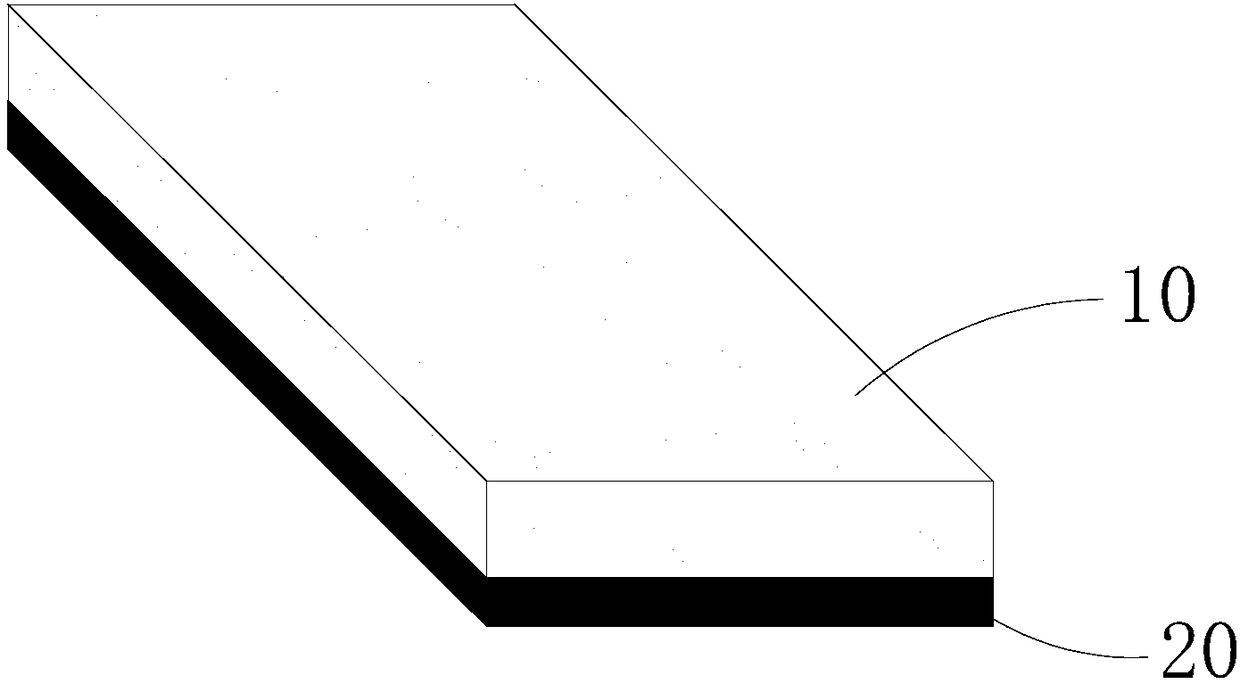

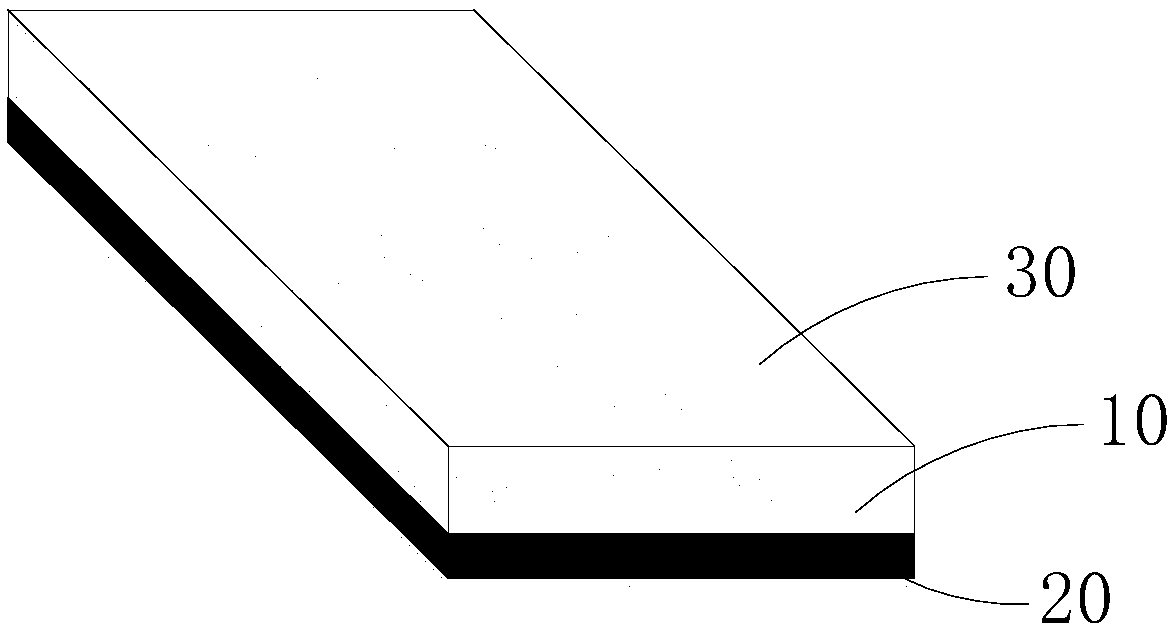

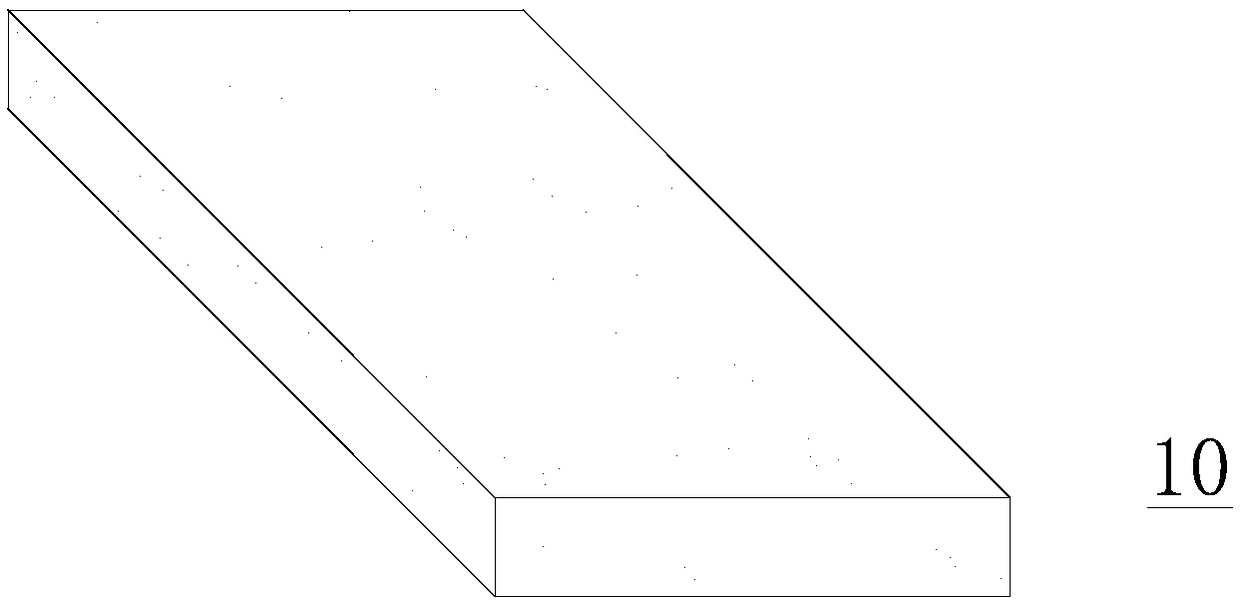

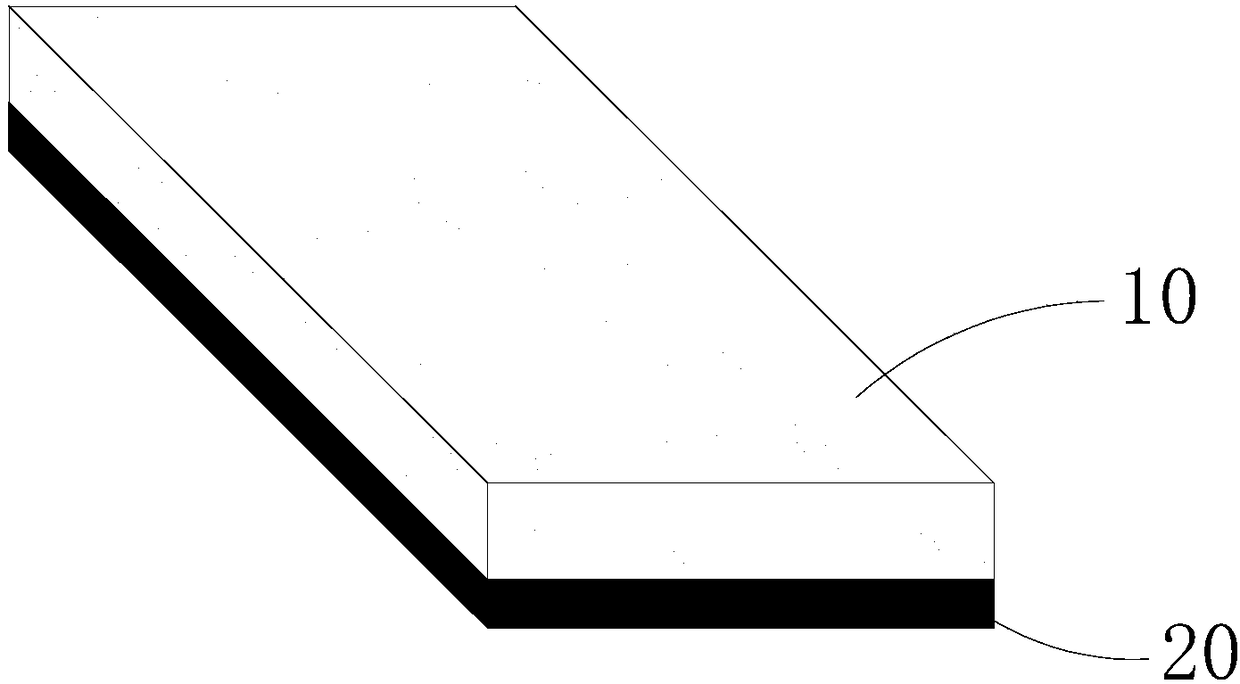

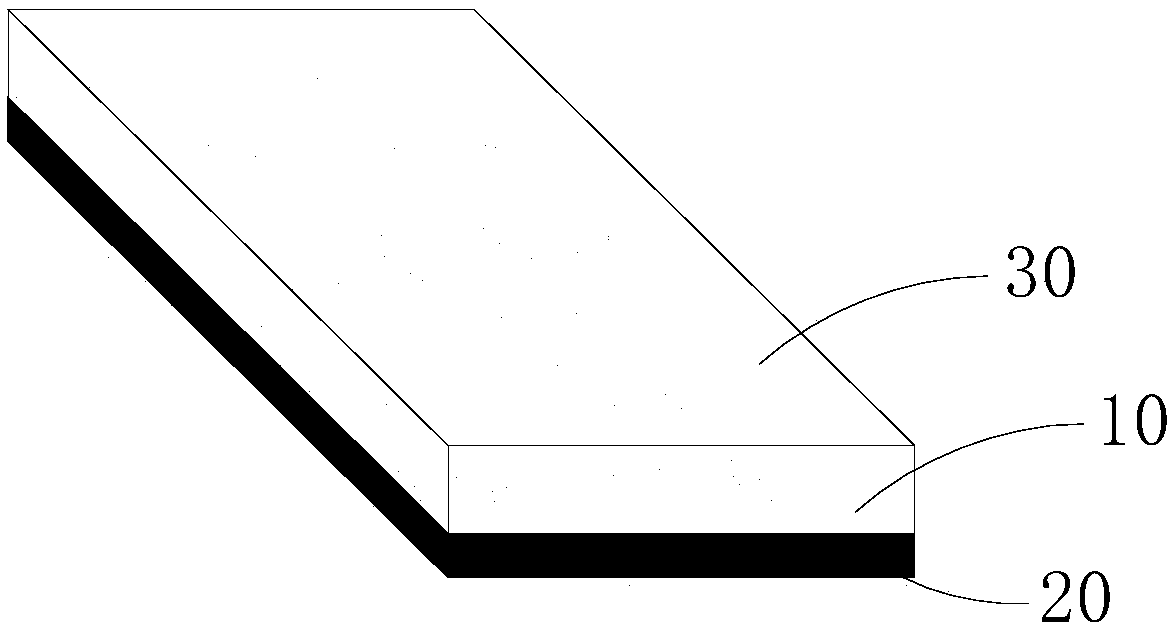

Solid wood composite board body decoration board and manufacturing method thereof

PendingCN108661268AImprove moisture resistanceImprove sound insulationCovering/liningsCalcium silicateSolid wood

The invention provides a solid wood composite board body decoration board and a manufacturing method thereof. The solid wood composite indoor decoration board comprises a board body, a back-coating paint layer, a permeating paint layer and a solid wood film. The board body is a calcium silicate board or a magnesium oxide board, and the front face and the back face of the board body are polished; the back face of the board body is coated with the back-coating paint layer; the front face of the board body is coated with the permeating paint layer; and the back face of the solid wood film is coated with a binder, and the solid wood film is attached to the front face of the board body through the binder.

Owner:深圳市优住住区产业化科技发展有限公司

PVC composite indoor decoration board and manufacturing method thereof

PendingCN108661275ALight in massQuality improvementCovering/liningsFlooringCalcium silicateMagnesium

The invention provides a PVC composite indoor decoration board and a manufacturing method thereof. The PVC composite indoor decoration board comprises a board body, a back-coating paint layer, a permeating paint layer, a binder and a PVC film. The board body is a calcium silicate board or a magnesium oxide board, and the front face and the back face of the board body are polished; the back face ofthe board body is coated with the back-coating paint layer; the front face of the board body is coated with the permeating paint layer; the permeating paint layer is coated with the binder; and the PVC film is located on the front face of the board body and laid on the binder, and the back face of the board body is vacuumized, so that the PVC film is tightly adsorbed to the front face of the board body.

Owner:深圳市优住住区产业化科技发展有限公司

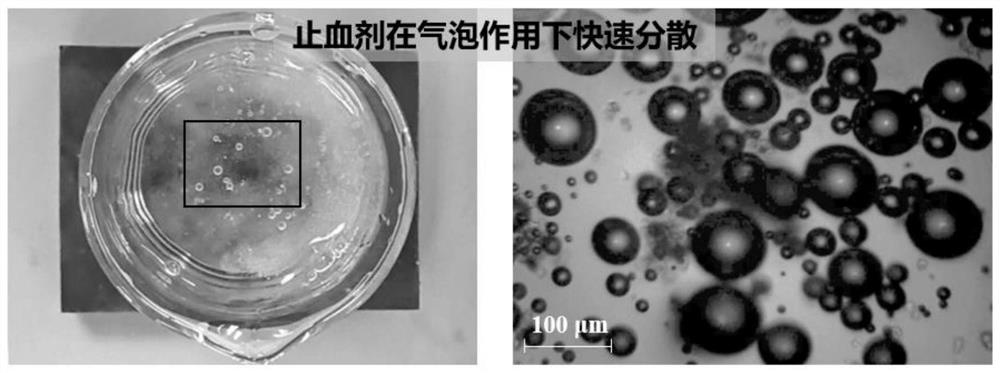

Preparation method of hemostatic agent with rapid diffusion mixing function

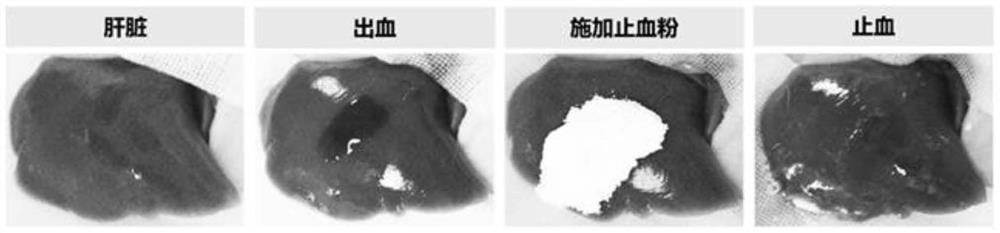

ActiveCN111035798AEffective hemostasisDiffusion fastSurgical adhesivesPharmaceutical delivery mechanismSodium bicarbonateWound surface

The invention aims at overcoming the defect that the existing hemostatic research and product cannot go deep into the wound to stop bleeding. The invention provides a preparation method of a hemostatic agent with rapid diffusion mixing function. The preparation method comprises following steps: depositing and growing sodium bicarbonate on esterified microporous starch to obtain esterified microporous starch / sodium bicarbonate particles; and immobilizing and assembling thrombin on the surfaces of the esterified microporous starch / sodium bicarbonate particles to obtain thrombin-assembled esterified microporous starch / sodium bicarbonate particles, and mixing the thrombin-assembled esterified microporous starch / sodium bicarbonate particles with a protonated acidic salt powder to obtain the hemostatic agent with rapid diffusion mixing function. By means of the characteristic that esterified microporous starch / sodium bicarbonate particles can achieve rapid diffusion mixing hemostasis in a specific microenvironment, the sealing effect is achieved on the whole blood cavity and the wound surface of a wound, and three-dimensional hemostasis of the wound is achieved.

Owner:SOUTHWEST UNIV

Filler dust eliminating apparatus used in baking tunnel during baking process of graphite manufacturing process

The present invention discloses a filler dust eliminating apparatus used in a baking tunnel during a baking process of a graphite manufacturing process, and relates to the field of graphite manufacturing. The apparatus comprises a rectangular base frame and a hopper frame installed on the base frame. Both axial sides of the base frame are provided with axial slide rails. The bottom of the hopper frame contacts the axial slide rails by slide apparatuses. The middle parts between the hopper frame and the two axial ends of the base frame are respectively provided with a rectangular sealing cover. Both axial ends of the sealing covers are respectively fixed on the two edges of the hopper frame, wherein the two edges of the hopper frame are relative to the base frame. According to the scheme of the present invention, the hopper can freely move above the baking tunnel by the base frame, it is ensured that the filler formed by mixing metallurgical coke and quartz sand, or river sand and the like can be uniformly filled in any positions in the baking tunnel; the dust generated during the filler pouring process is prevented from diffusion into the air by the sealing cover on the base frame; with the sealing cover, the sealing of the tunnel mouth can be remained during the hopper frame moving process so as to prevent the diffusion of the dust to the maximal degree; with the dust discharge mouth on the base frame, the dust dissipation time in the tunnel can be shortened.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

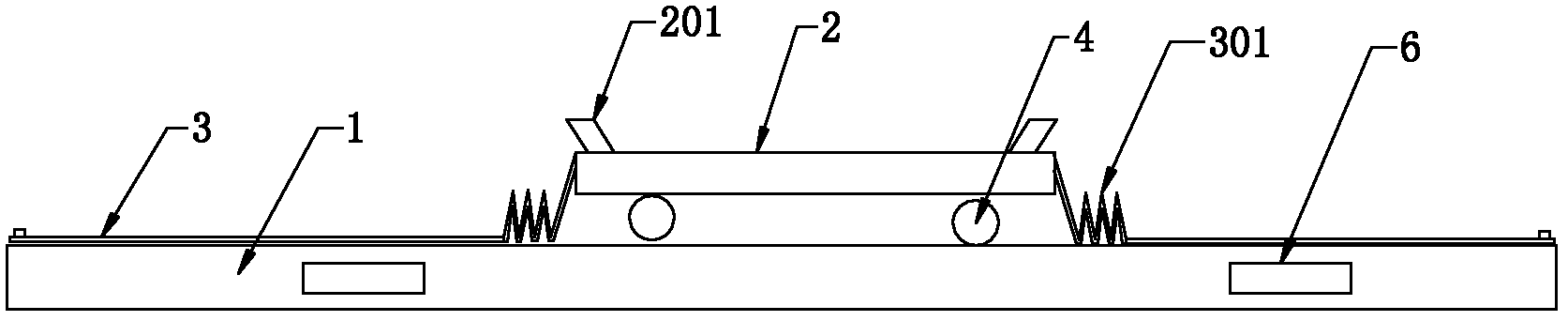

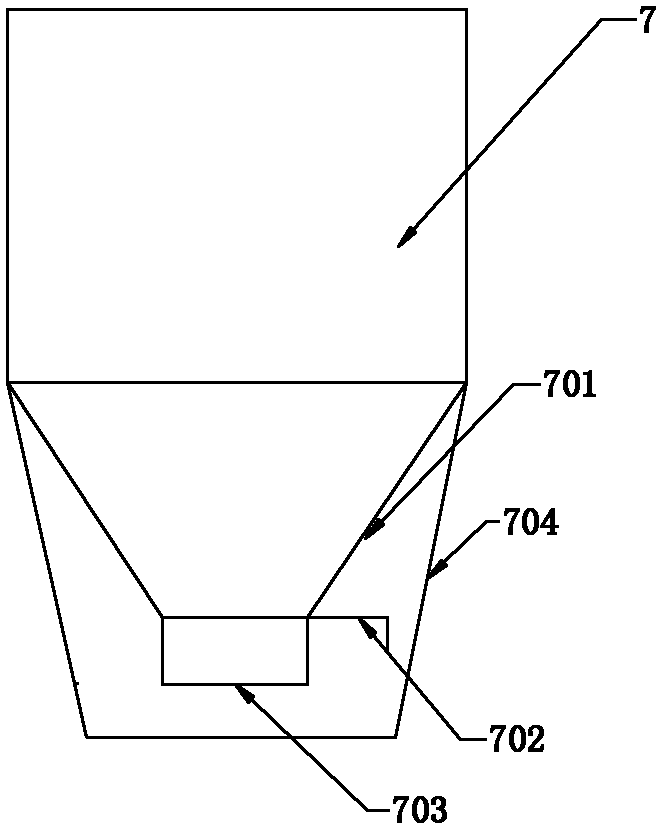

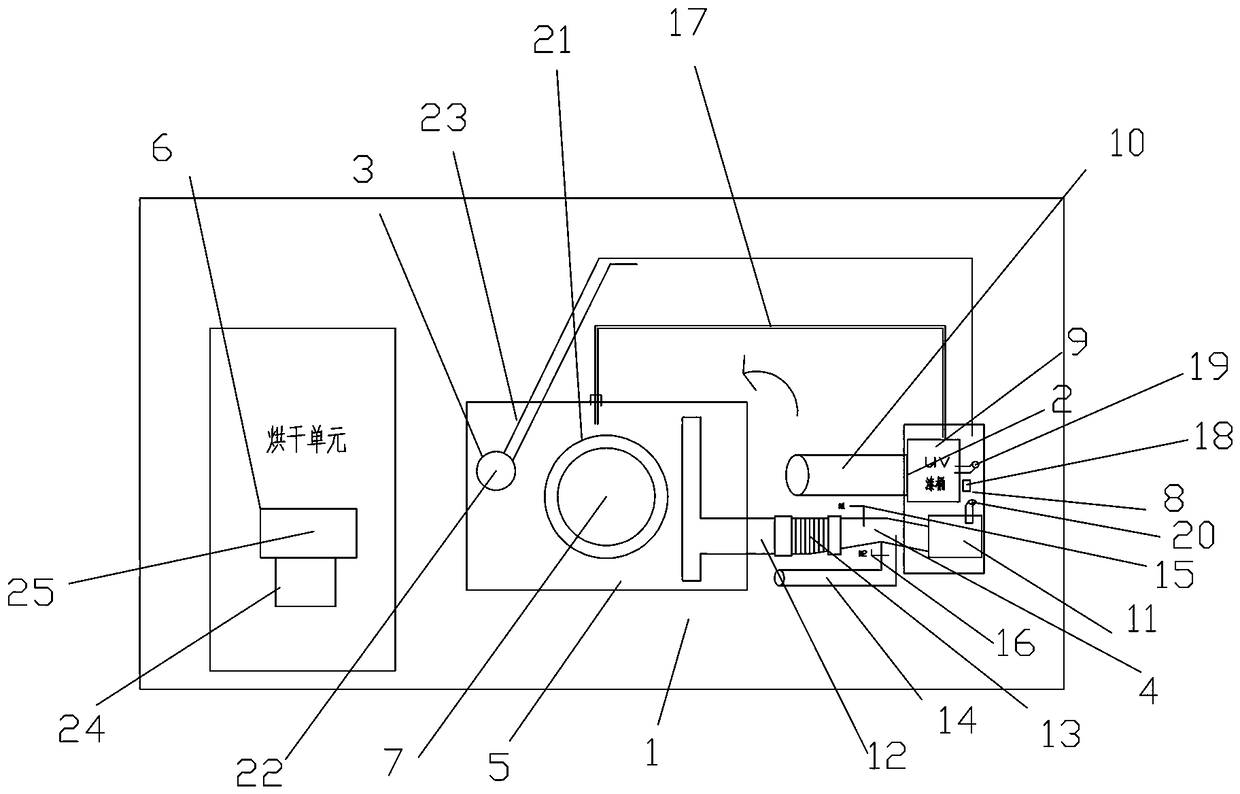

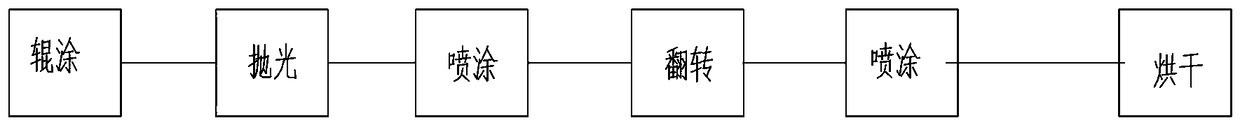

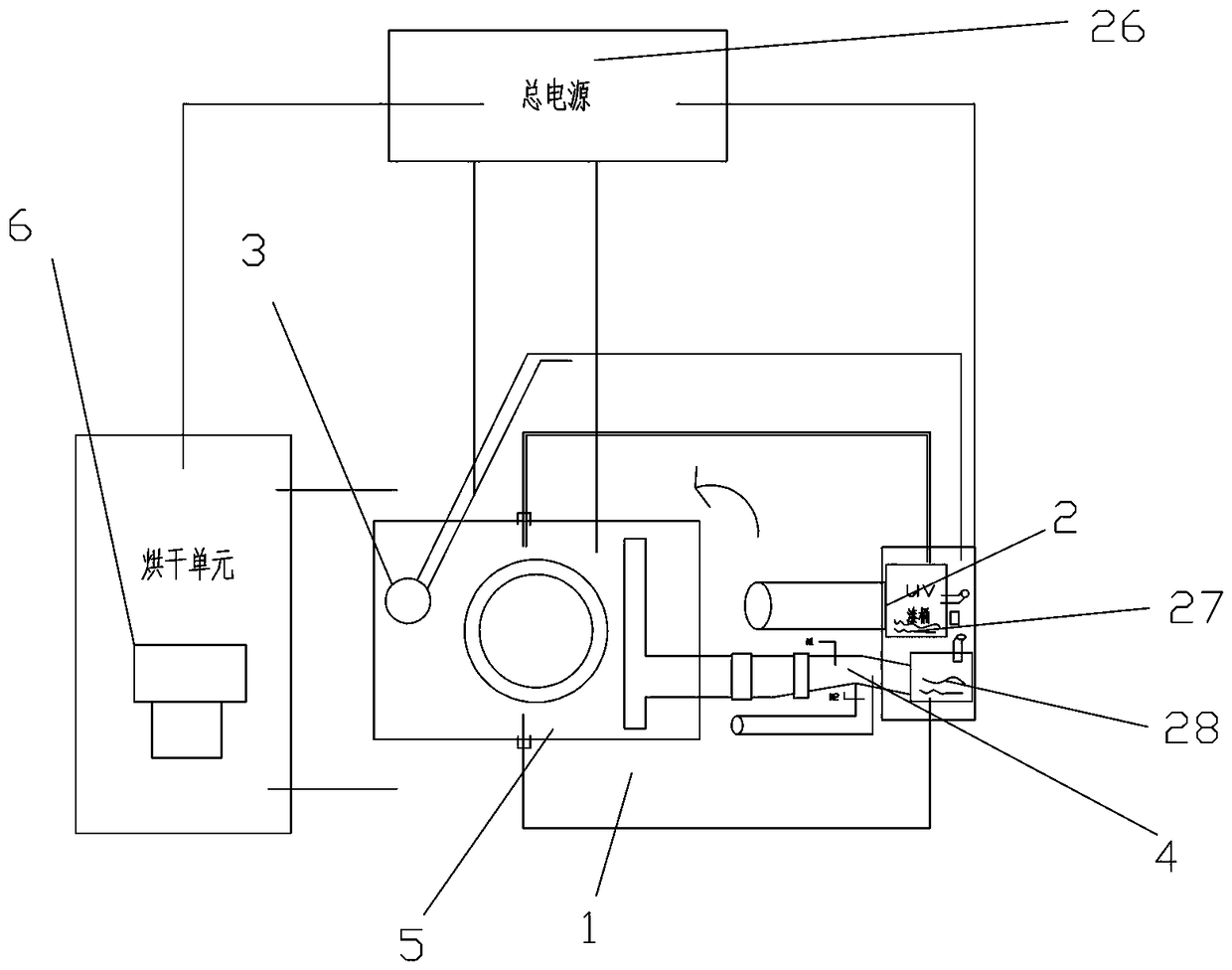

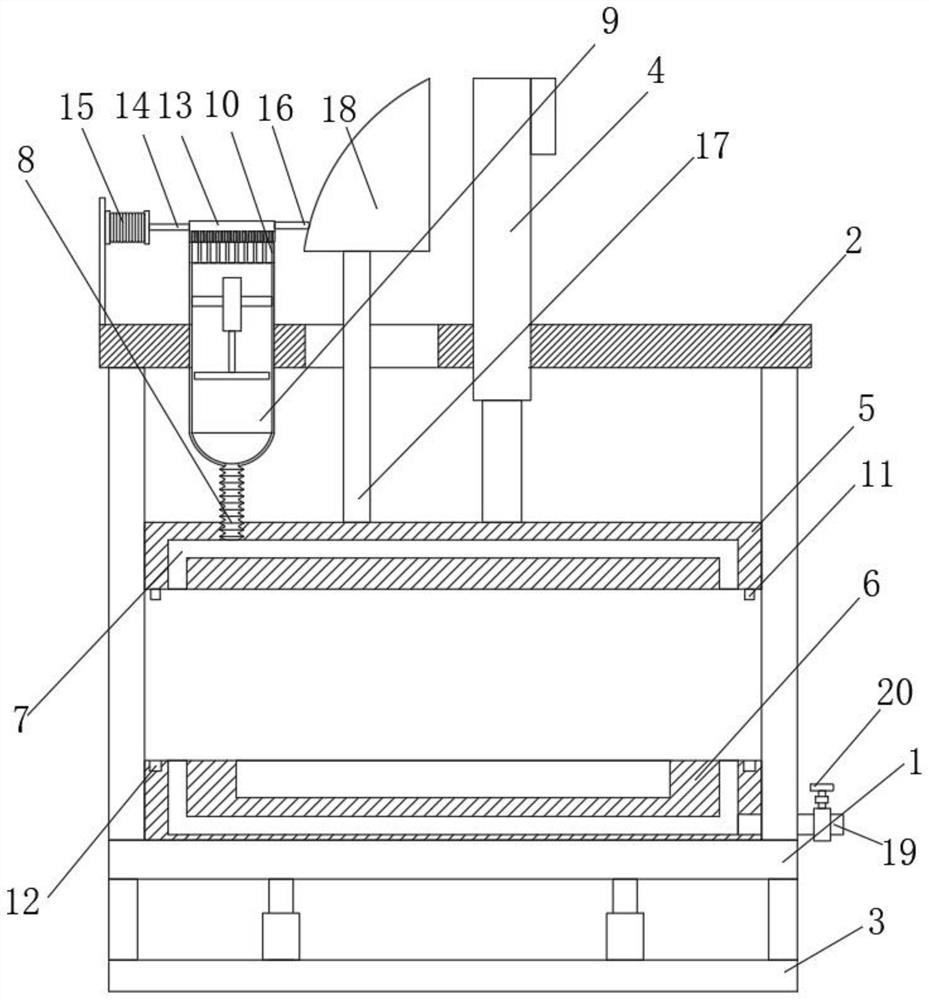

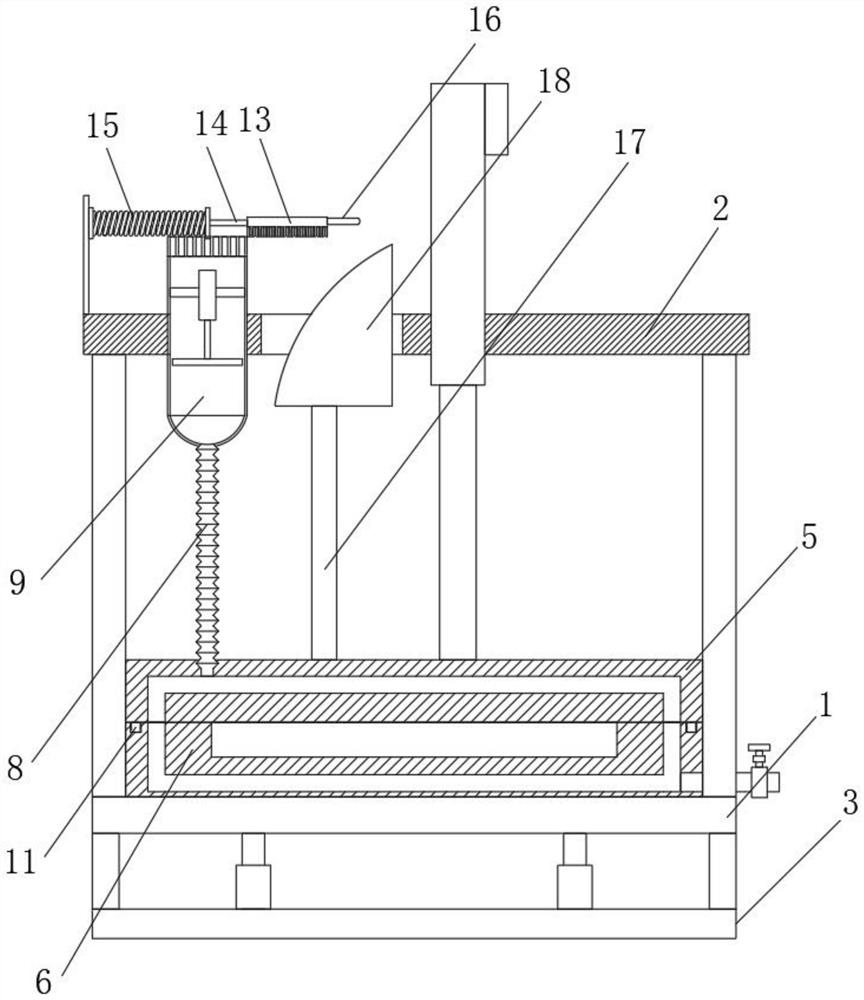

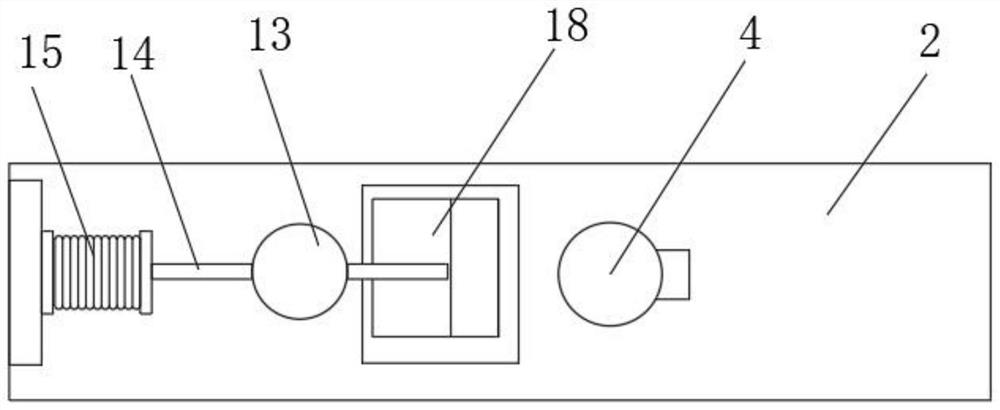

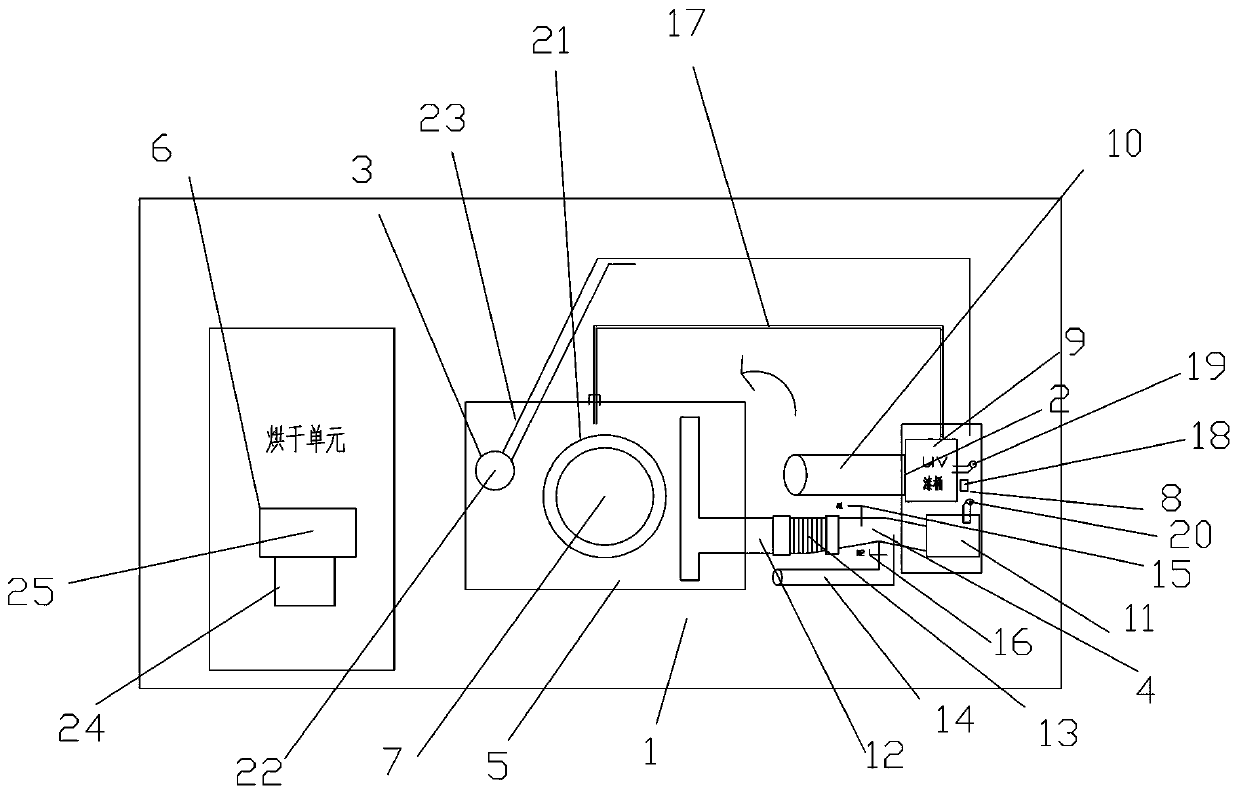

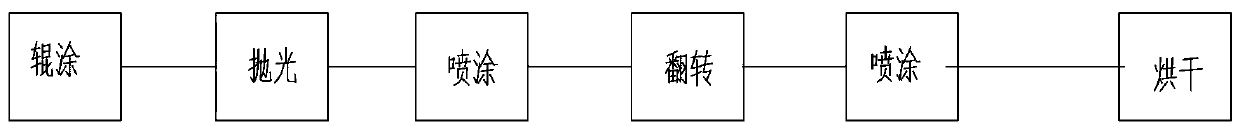

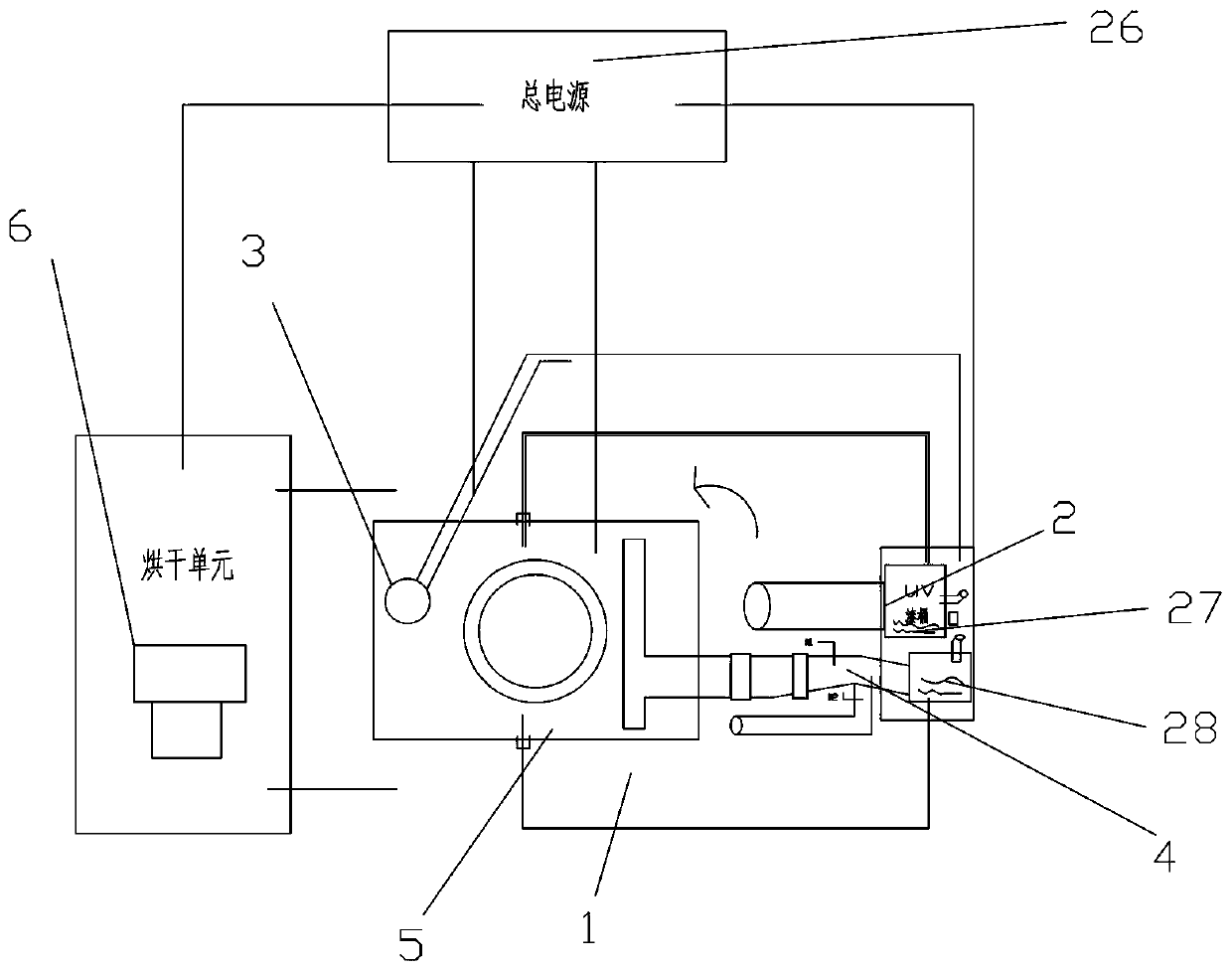

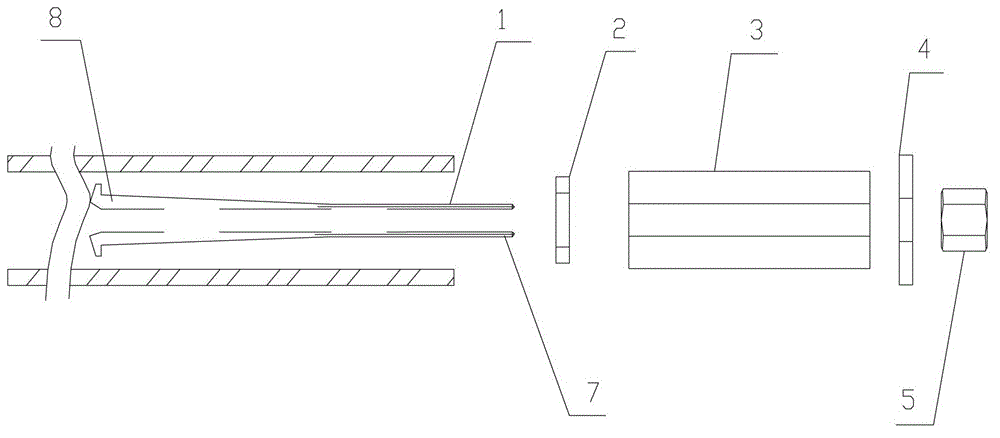

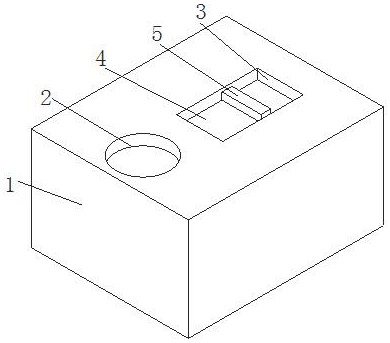

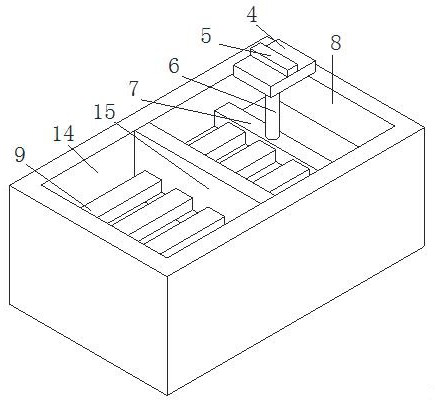

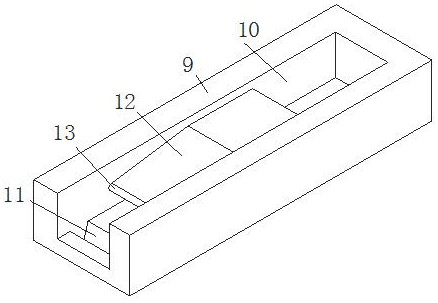

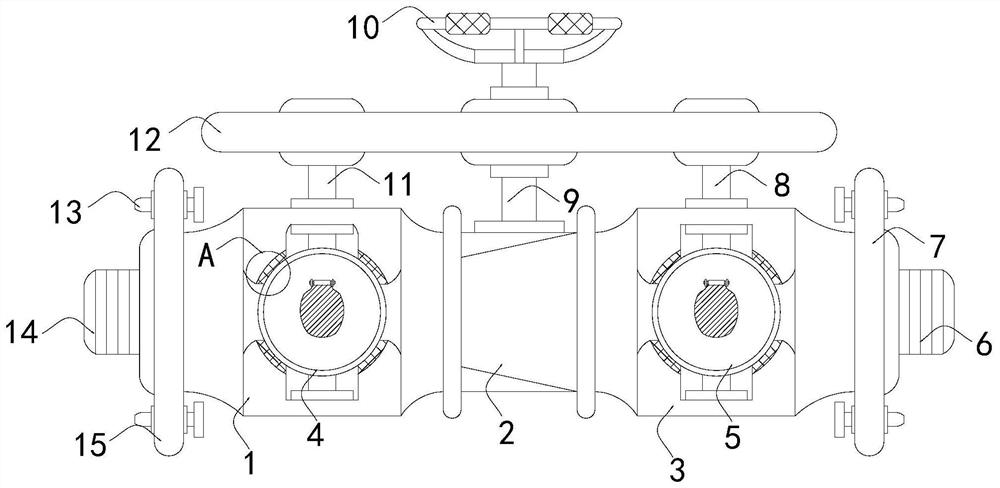

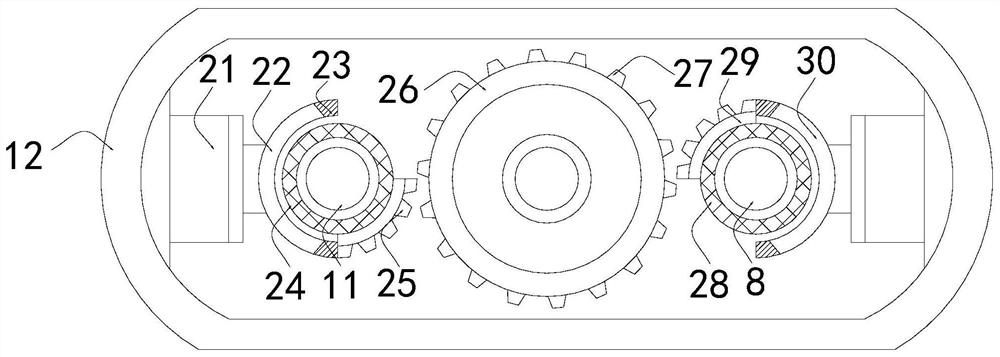

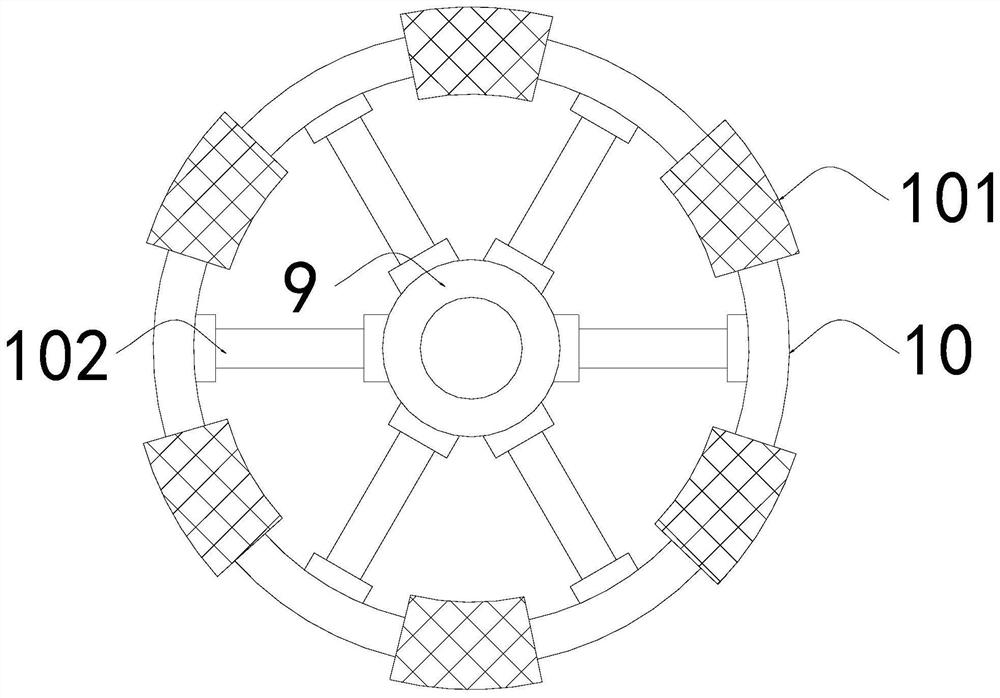

Spray coating system for environmentally-friendly water-based door sheet

ActiveCN108057539ATo achieve a closed effectEasy to spray laterSpraying apparatusPretreated surfacesWater basedTemperature control

The invention discloses a spray coating system for an environmentally-friendly water-based door sheet. The spray coating system comprises a working platform, a roller coating unit, a polishing unit, aspray coating unit, an overturn unit and a drying unit, wherein the roller coating unit, the polishing unit, the spray coating unit, the overturn unit and the baking unit are arranged on the workingplatform; the working platform comprises a lifting table and a control table, and the roller coating unit comprises a first paint bucket and a first paint spray gun; the polishing unit comprises a polishing machine and a mechanical gripper, and the spray coating unit comprises a second paint bucket and a second paint spray gun; the overturn unit comprises a mechanical arm which is connected with the control table and has an overturn and translation functions; and the drying unit comprises a dryer and a temperature control instrument. The spray coating system has the technical effects that roller coating equipment conducts UV paint roller-coating treatment for the edge part of the door sheet, so that the surface of the sheet achieves a closed effect; the surface of the sheet is polished bythe polishing machine, so that the surface of the sheet is smooth and has no bright spot so as to be convenient for later spray coating; and water-based paint spray-coated on the door sheet is dried through a drying chamber.

Owner:徐仁助

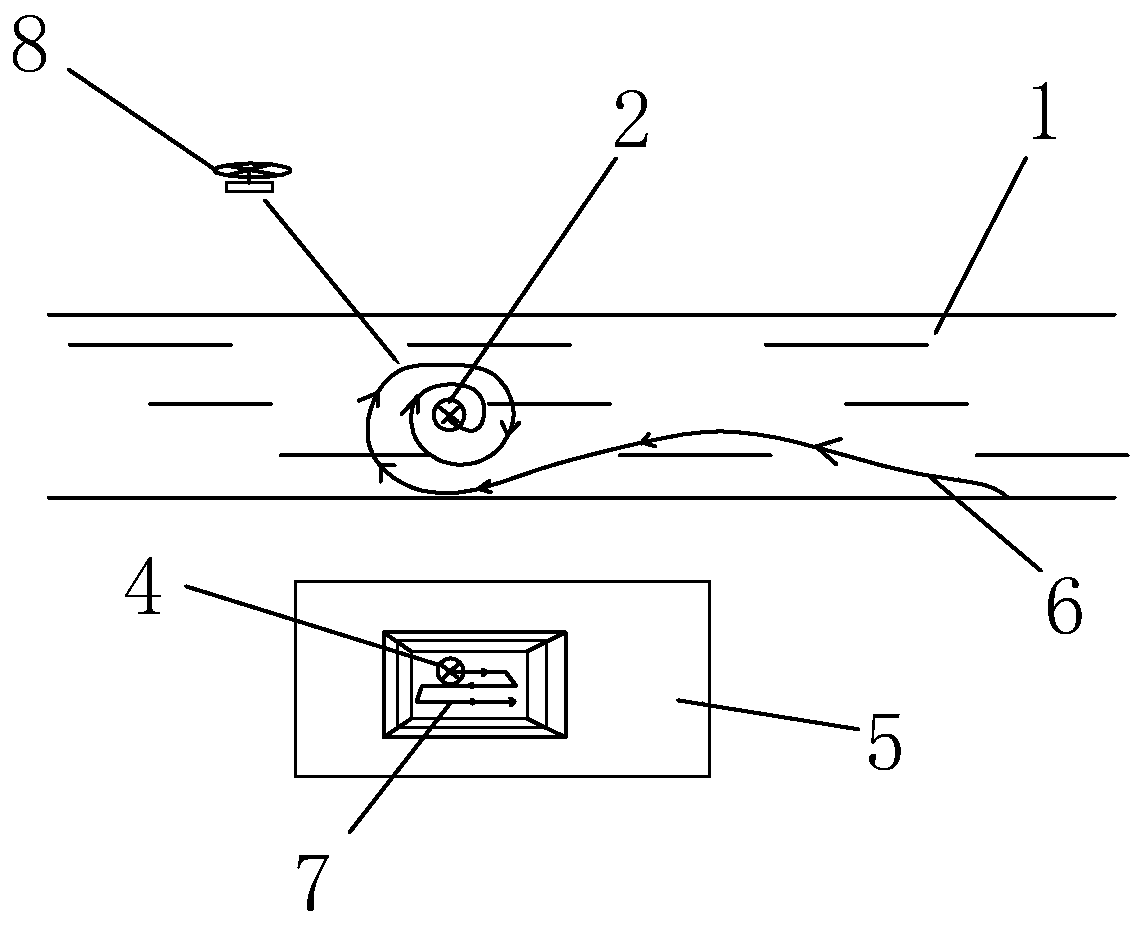

Aerobic tank with uniform aeration and large reaction area

InactiveCN104445594AEasy to handleImprove processing efficiencyTreatment using aerobic processesBiological treatment apparatusSewage treatmentAeration

The invention discloses an aerobic tank with uniform aeration and large reaction area. The aerobic tank comprises a tank body, the bottom of the tank body is provided with a mixing zone, an aerobic zone is arranged above the mixing zone, a gas-liquid separation zone is arranged above the aerobic zone, the aerobic zone is internally provided with an aeration pipe, a filling layer is disposed above the aeration pipe, the height of the aerobic zone is 2-3m, an aeration mesh plate is arranged on the aeration pipe, the aeration mesh plate is connected to the aeration pipe through a cross bar, both ends of the filling layer are provided with a rotating member, and the rotating members are fixedly connected to the tank body. The arrangement of the aeration meshes enables uniform aeration, the sewage treatment effect is better, and the filling layer can rotate, thus increasing the reaction contact area, and improving the sewage treatment efficiency.

Owner:上海伟阳纸业有限公司

a sealed box

Owner:JIANGSU YONGSHANG ENERGY TECH

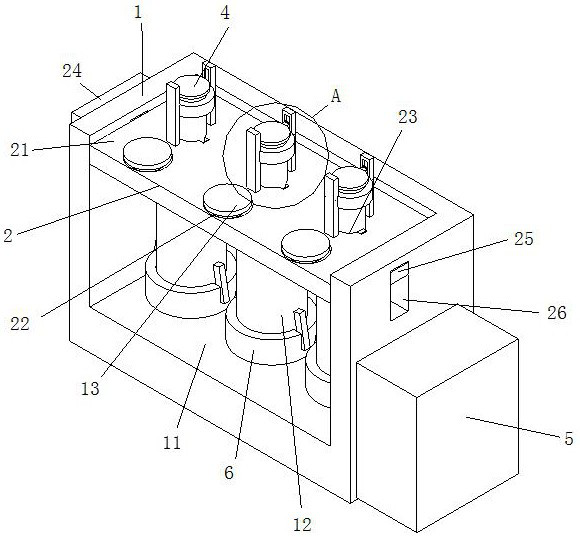

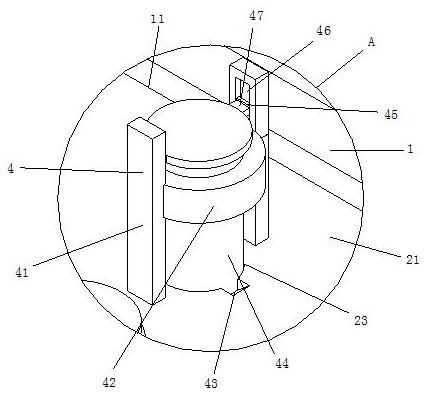

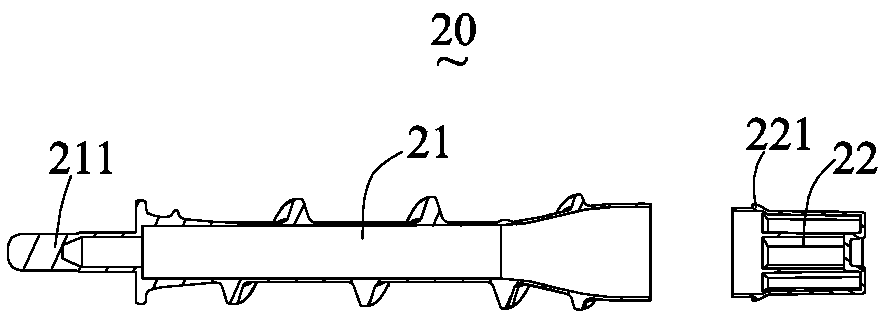

Medicine dispensing and infusion combined device for intravenous infusion center

ActiveCN114272811AImprove dispensing efficiencyMeet the needs of rapid production and dispensingRotating receptacle mixersTransportation and packagingPharmacy medicineApparatus instruments

The invention relates to the technical field of medical apparatus and instruments, and discloses a medicine dispensing and transfusion combined device for an intravenous administration center, which comprises a workbench, a mixing bottle and a sealing cover, an inner groove is formed in the side surface of the workbench, the mixing bottle is placed in the inner groove, a shielding mechanism is movably connected in the inner groove, and three placing mechanisms are equally arranged on the bottom wall of the inner groove. The lower portions of the three placement mechanisms are controlled by arranging a kinetic energy mechanism, the shielding mechanism comprises a partition plate, three leakage holes are formed in the upper surface of the partition plate in an equally-spaced mode, and a short-distance sealing mechanism is arranged above each leakage hole. The three rotating columns are driven to rotate synchronously while the transmission crawler belt rotates, at the moment, medicine in the mixing bottles is rotated and mixed under centrifugal force, multiple kinds of medicine can be dispensed at a time by arranging the multiple mixing bottles, the medicine dispensing efficiency is improved, and the requirement for rapid production and medicine dispensing is met.

Owner:郑州大学第三附属医院

Construction waste loader transporter

InactiveCN108749538ALoad capacity utilizationEnsure personal safetyUsing liquid separation agentVehicle cleaningArchitectural engineeringWater transporter

The invention relates to the technical field of construction waste loader transporter and discloses a construction waste loader transporter. According to the construction waste loader transporter, theproblem that a rear door of an existing loader transporter cannot be automatically opened and closed is solved. In order to solve the technical problem, the construction waste loader transporter comprises a bottom plate; the front surface and the back surface of the top of the bottom plate are fixedly connected with the bottom of two side plates; a protection box is fixedly connected to the bottom of the bottom plate; a first motor is fixedly connected to the bottom of the internal wall of the protection box; and a driving belt wheel is fixedly connected to an output end of the first motor. According to the construction waste loader transporter, through coordination of a crank arm rod, a hinging block, a moving block and a slide block, the rear door moves to one sides of the side plates so that the rear door is parallel to the side plates; and therefore, the rear door of the loader transporter can realize an effect that the rear door is automatically opened and closed; a phenomenon that construction personnel need to specially get off to manually open the rear door is avoided; and the personal safeties of the construction personnel are guaranteed.

Owner:绿源环保有限公司

A kind of preparation method of hemostatic agent with diffusion mixing function

ActiveCN111035798BEffective hemostasisDiffusion fastSurgical adhesivesPharmaceutical delivery mechanismSodium bicarbonateWound surface

The invention aims at overcoming the defect that the existing hemostatic research and product cannot go deep into the wound to stop bleeding. The invention provides a preparation method of a hemostatic agent with rapid diffusion mixing function. The preparation method comprises following steps: depositing and growing sodium bicarbonate on esterified microporous starch to obtain esterified microporous starch / sodium bicarbonate particles; and immobilizing and assembling thrombin on the surfaces of the esterified microporous starch / sodium bicarbonate particles to obtain thrombin-assembled esterified microporous starch / sodium bicarbonate particles, and mixing the thrombin-assembled esterified microporous starch / sodium bicarbonate particles with a protonated acidic salt powder to obtain the hemostatic agent with rapid diffusion mixing function. By means of the characteristic that esterified microporous starch / sodium bicarbonate particles can achieve rapid diffusion mixing hemostasis in a specific microenvironment, the sealing effect is achieved on the whole blood cavity and the wound surface of a wound, and three-dimensional hemostasis of the wound is achieved.

Owner:SOUTHWEST UNIV

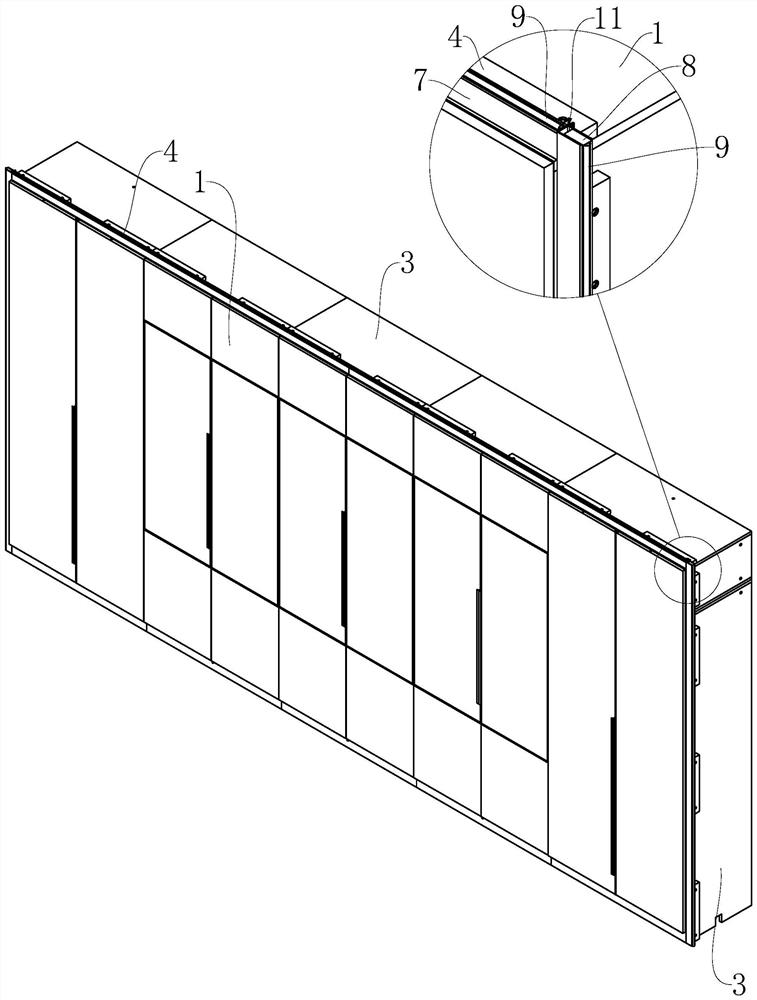

Method for fully filling uneven gap between cabinet body and wall surface

PendingCN114766848AFully filledTo achieve the fit effectFittingMacroscopic scaleStructural engineering

Owner:ZHEJIANG SUNON FURNITURE MFG

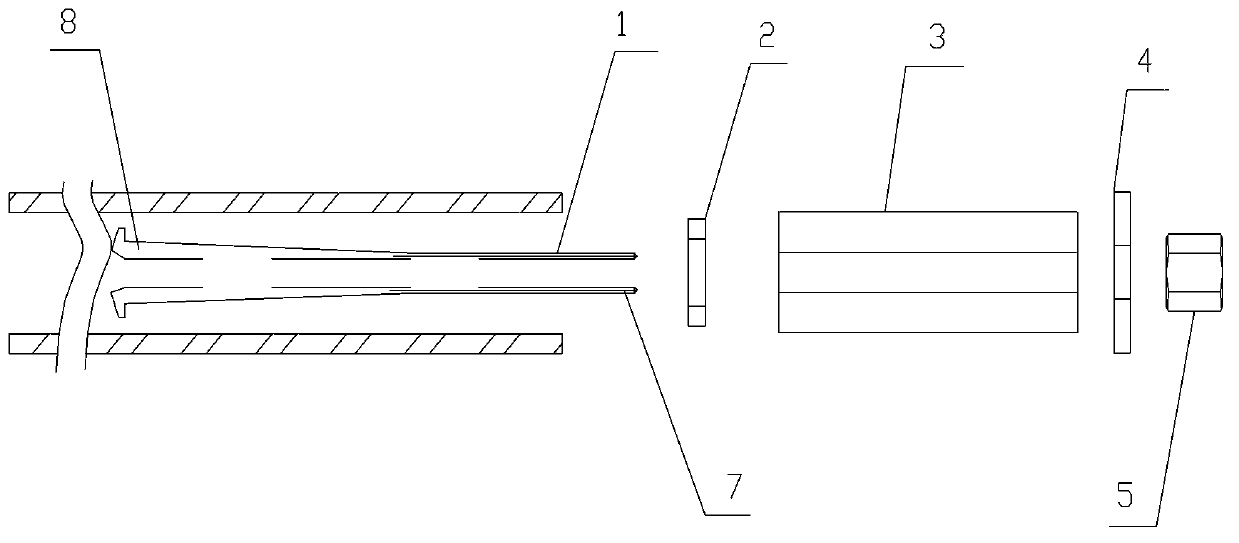

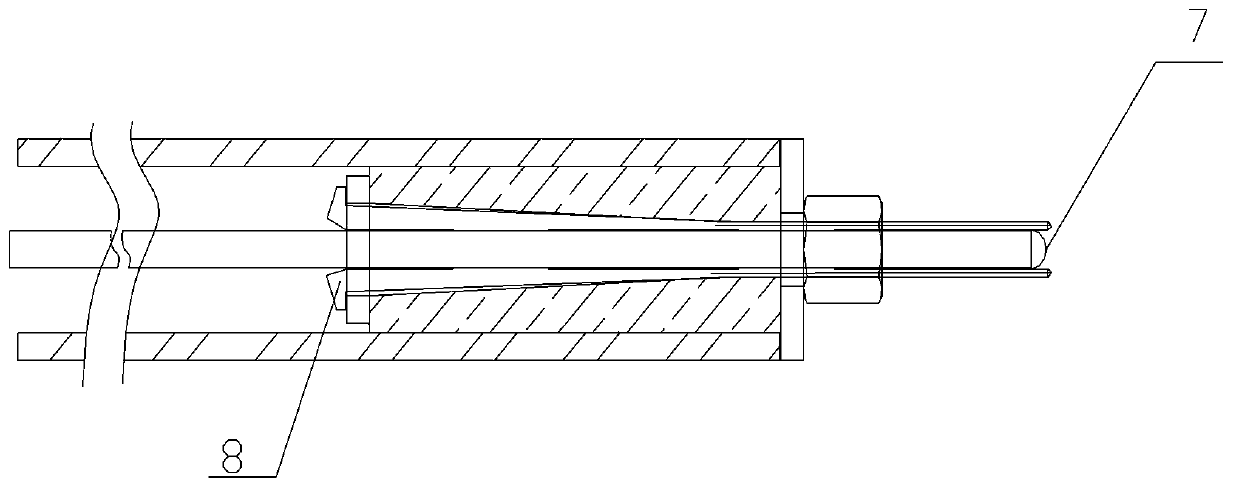

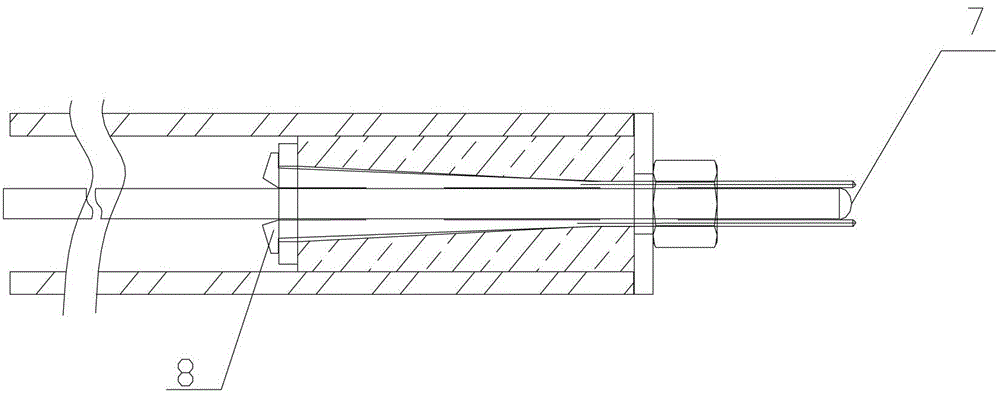

Electrode leading-out terminal

InactiveCN103391655AIncrease contact areaLarge area transmission is goodElectric discharge heatingStructural engineeringElectrical and Electronics engineering

The invention relates to the thermoelectricity field, in particular to an electrode leading-out terminal. The electrode leading-out terminal comprises an electrode leading-out casing, a hollow expansion bolt, a first annular spacer, a second annular spacer, an annular expansion body, a nut and a lead wire. The expansion bolt sequentially penetrates the first annular spacer, the annular expansion body, the second annular spacer and the nut and is in threaded connection with the nut. The lead wire penetrates the expansion bolt. The expansion end of the expansion bolt is located inside the electrode leading-out casing, and one end of the expansion bolt connected with the nut is located outside the electrode leading-out casing. The expansion end is provided with the outer extending edge, and the outer extending edge, the first annular spacer, the annular expansion body, the second annular spacer and the nut are sequentially and tightly in contact in the direction from the expansion end to one end of the expansion bolt connected with the nut. The second annular spacer is in tight contact with the end face of the electrode leading-out casing. The electrode leading-out terminal can prevent assemblies from sliding through large thrust face and achieve the airtight effect.

Owner:曲颜发

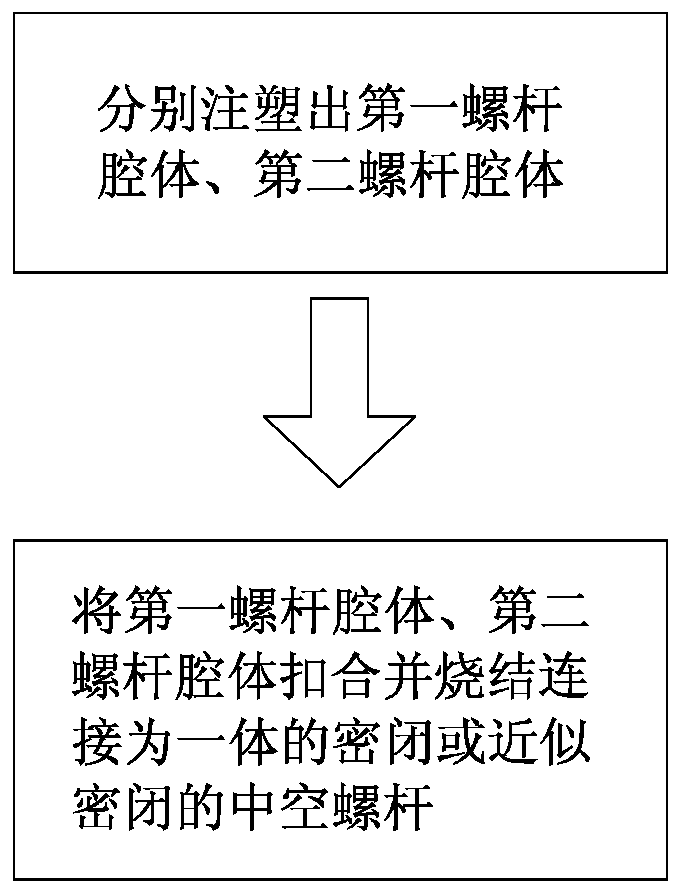

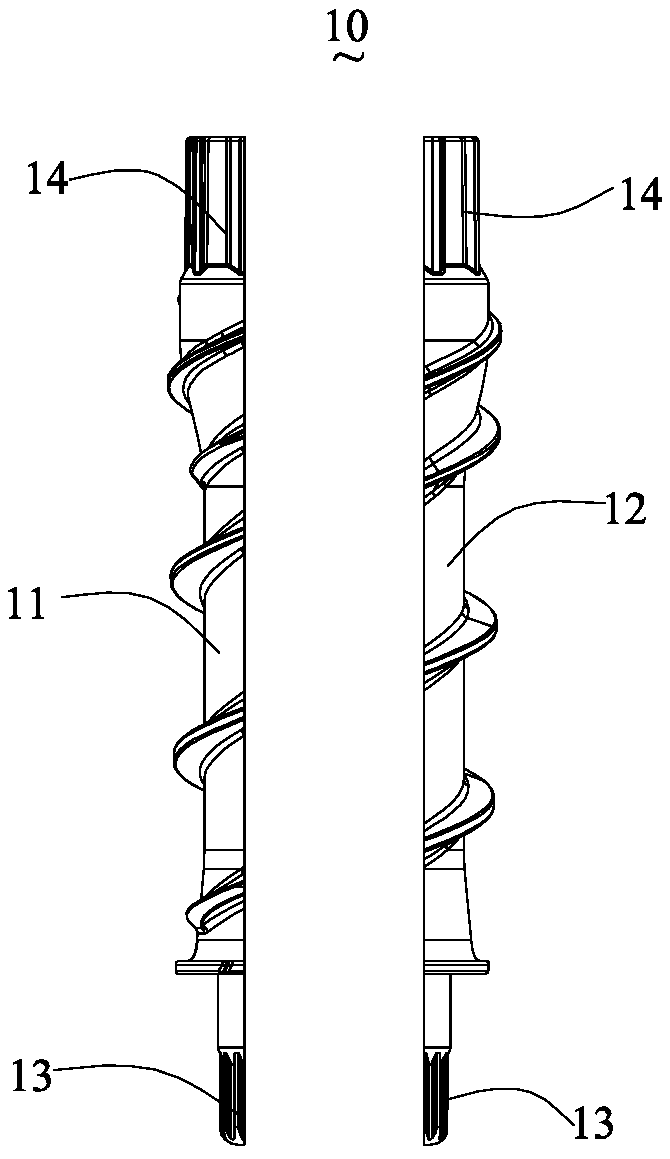

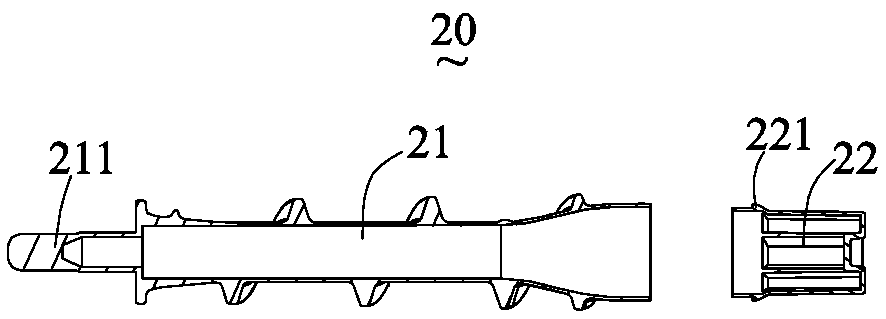

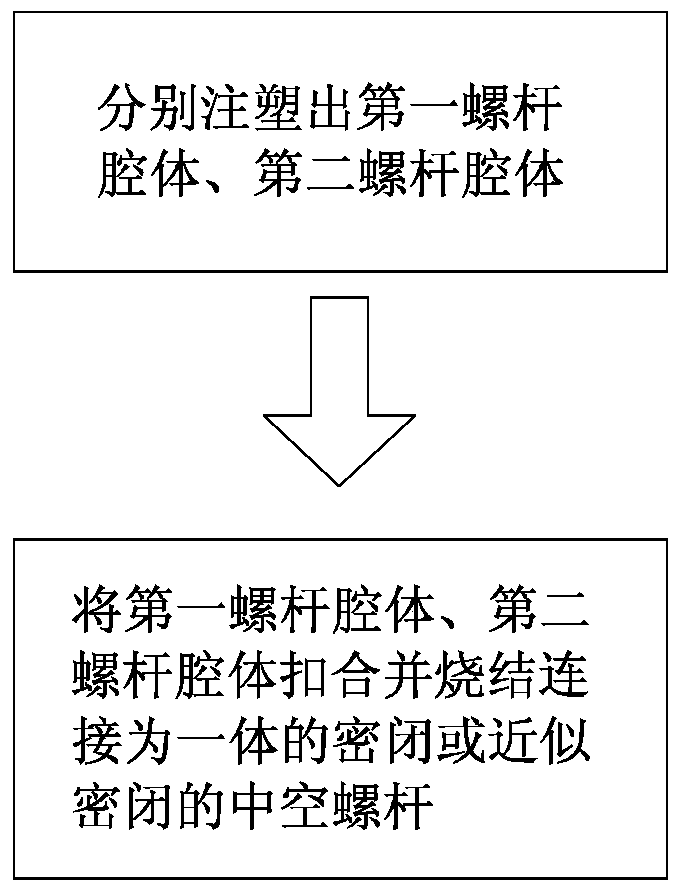

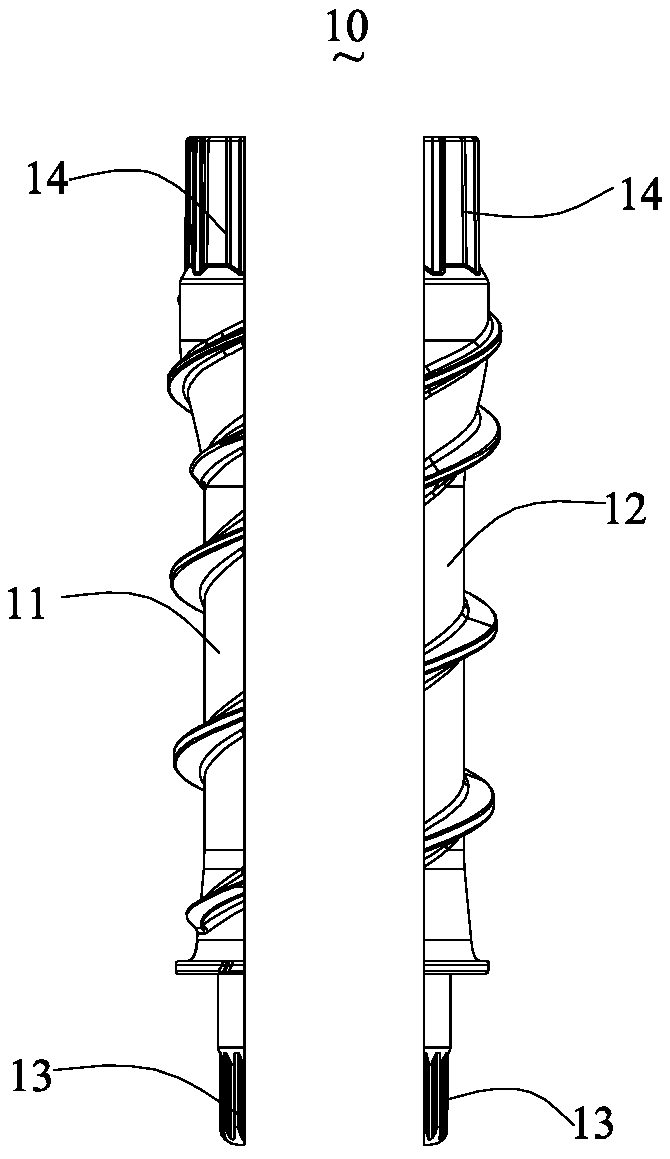

A kind of manufacturing method of screw rod for food processing machine and screw rod thereof

The invention relates to a manufacturing method for a screw for a food processor. A first screw cavity and a second screw cavity are obtained through injection molding, and then the first screw cavityand the second screw cavity are buckled and connected to form the integrated closed or approximately-closed hollow screw in a sintering manner. Compared with the prior art, the closed or approximately-closed hollow screw can be conveniently manufactured through the method, the closed or approximately-closed hollow screw has the beneficial effects that foods are not prone to being accumulated in amiddle cavity, the screw can be washed more conveniently and can be more sanitary, the screw manufactured through the method allows the wall thickness of the screw to be flexibly adjusted, the weightof the screw is greatly reduced, a large number of manufacturing materials are saved, the cost is greatly reduced, and according to incomplete estimation, the cost can be reduced by at least 40%; inaddition, by means of the manufacturing method, the screw can be good in surface smoothness, polishing is not needed, and the screw is easy to wash after being used; and in addition, the manufacturingmethod is high in yield, volume production is facilitated, and the production efficiency is greatly improved.

Owner:JOYOUNG CO LTD

Manufacturing method for screw for food processor and screw

The invention relates to a manufacturing method for a screw for a food processor. A first screw cavity and a second screw cavity are obtained through injection molding, and then the first screw cavityand the second screw cavity are buckled and connected to form the integrated closed or approximately-closed hollow screw in a sintering manner. Compared with the prior art, the closed or approximately-closed hollow screw can be conveniently manufactured through the method, the closed or approximately-closed hollow screw has the beneficial effects that foods are not prone to being accumulated in amiddle cavity, the screw can be washed more conveniently and can be more sanitary, the screw manufactured through the method allows the wall thickness of the screw to be flexibly adjusted, the weightof the screw is greatly reduced, a large number of manufacturing materials are saved, the cost is greatly reduced, and according to incomplete estimation, the cost can be reduced by at least 40%; inaddition, by means of the manufacturing method, the screw can be good in surface smoothness, polishing is not needed, and the screw is easy to wash after being used; and in addition, the manufacturingmethod is high in yield, volume production is facilitated, and the production efficiency is greatly improved.

Owner:JOYOUNG CO LTD

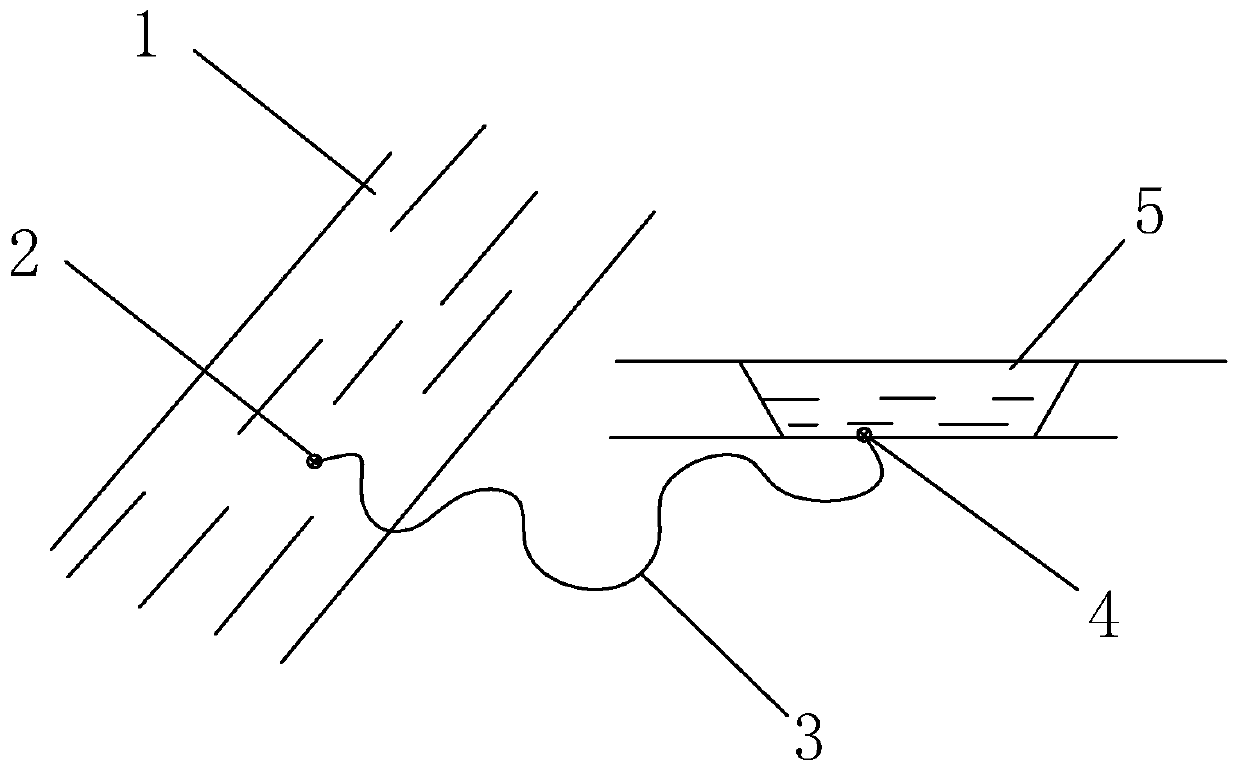

Seepage-proofing and seepage-resisting construction method for foundation pit close to river

The invention discloses a seepage-proofing and seepage-resisting construction method for a foundation pit close to a river. According to the construction method, a dye indication method, a technologyof sealing a water seepage point by using a sealed container, a technology of pouring fine stone waterproof concrete in different steps and a technology of sealing a river bed surface by using waterproof concrete are combined, and a water seepage opening is blocked from a water seepage source to solve the water seepage problem. The construction process mainly comprises the steps of carrying out construction preparation; determining a water seepage opening of a karst cave at the bottom of a river bed by using the dye indication method; sealing the vortex position of the water seepage opening through the sealed container; pouring the fine stone waterproof concrete into the sealed container in different steps; meanwhile, pumping water from the foundation pit; after flowing water in the foundation pit is completely stopped, sealing the river bed surface by using the waterproof concrete; and lifting the sealed container to leave the river surface. According to the construction method, the water seepage problem can be solved from the water seepage source, the water seepage point is directly blocked, ultra-large mechanical equipment or complex equipment is not needed, and the mechanical equipment used for construction is simple and is easy and convenient to operate.

Owner:广西建工第五建筑工程集团有限公司

Environment-protecting efficient heat dissipation injection mold

InactiveCN112092320ATo achieve a closed effectAvoid accumulationFouling preventionDispersed particle filtrationCold airThermodynamics

The invention relates to the technical field of injection molds, and particularly discloses an environment-protecting efficient heat dissipation injection mold. The environment-protecting efficient heat dissipation injection mold comprises a base, wherein a support is fixedly connected to the left side and the right side of the top face of the base, and an ejection mechanism is fixedly connected to the bottom face of the base; a hydraulic rod is fixedly connected to the top face of the support, an upper mold base is fixedly connected to the bottom end of the hydraulic rod, and a lower mold base is fixedly connected to the top face of the base; and a mold cavity is formed in the top face of the lower mold base, and cavities are formed inside the upper mold base and the lower mold base. According to the environment-protecting efficient heat dissipation injection mold, an air cooler is arranged on the support, and meanwhile, an air inlet pipe is arranged in a matched mode so that the cavities in the upper mold base and the lower mold base can be inflated through the air cooler, the interiors of the cavities are filled with cold air, then the mold cavity is located in a low-temperatureenvironment, the effect of cooling raw materials inside the mold cavity is achieved, and cooling molding of the raw materials is accelerated.

Owner:中山市泽一照明科技有限公司

Spraying system for environmentally friendly water-based door panels

ActiveCN108057539BTo achieve a closed effectEasy to spray laterSpraying apparatusPretreated surfacesTemperature controlSpray coating

The invention discloses a spray coating system for an environmentally-friendly water-based door sheet. The spray coating system comprises a working platform, a roller coating unit, a polishing unit, aspray coating unit, an overturn unit and a drying unit, wherein the roller coating unit, the polishing unit, the spray coating unit, the overturn unit and the baking unit are arranged on the workingplatform; the working platform comprises a lifting table and a control table, and the roller coating unit comprises a first paint bucket and a first paint spray gun; the polishing unit comprises a polishing machine and a mechanical gripper, and the spray coating unit comprises a second paint bucket and a second paint spray gun; the overturn unit comprises a mechanical arm which is connected with the control table and has an overturn and translation functions; and the drying unit comprises a dryer and a temperature control instrument. The spray coating system has the technical effects that roller coating equipment conducts UV paint roller-coating treatment for the edge part of the door sheet, so that the surface of the sheet achieves a closed effect; the surface of the sheet is polished bythe polishing machine, so that the surface of the sheet is smooth and has no bright spot so as to be convenient for later spray coating; and water-based paint spray-coated on the door sheet is dried through a drying chamber.

Owner:徐仁助

Electrode terminal

InactiveCN103391655BIncrease contact areaPrevent each other from slidingElectric discharge heatingEngineeringExpansion joint

The invention relates to the thermoelectricity field, in particular to an electrode leading-out terminal. The electrode leading-out terminal comprises an electrode leading-out casing, a hollow expansion bolt, a first annular spacer, a second annular spacer, an annular expansion body, a nut and a lead wire. The expansion bolt sequentially penetrates the first annular spacer, the annular expansion body, the second annular spacer and the nut and is in threaded connection with the nut. The lead wire penetrates the expansion bolt. The expansion end of the expansion bolt is located inside the electrode leading-out casing, and one end of the expansion bolt connected with the nut is located outside the electrode leading-out casing. The expansion end is provided with the outer extending edge, and the outer extending edge, the first annular spacer, the annular expansion body, the second annular spacer and the nut are sequentially and tightly in contact in the direction from the expansion end to one end of the expansion bolt connected with the nut. The second annular spacer is in tight contact with the end face of the electrode leading-out casing. The electrode leading-out terminal can prevent assemblies from sliding through large thrust face and achieve the airtight effect.

Owner:曲颜发

Environment-friendly combustion equipment for environment-friendly power plant

InactiveCN113483346APromote absorptionEasy to handleDispersed particle filtrationLighting and heating apparatusPower stationCombustion

The invention relates to the technical field of combustion equipment, and discloses environment-friendly combustion equipment for an environment-friendly power plant. The environment-friendly combustion equipment comprises a cleaning box, an inlet is formed in the upper side of the cleaning box, a sliding groove is formed in the upper side of the cleaning box, a sliding plate is slidably connected into the sliding groove, a pulling plate is fixedly connected to the surface of the sliding plate, and the lower surface of the pulling plate is fixedly connected with a connecting rod. According to the environment-friendly combustion equipment for the environment-friendly power plant, through the shape design of an outer barrel and an inner barrel, under the air draft effect of a suction fan, combustion gas is extruded and filtered in the outer barrel and the inner barrel, and in this way, through the curve shape of a cleaning column, long-time contact is achieved during gas absorption, so that a good adsorption effect is achieved during the contact of the gas and the cleaning column; and the interior of the outer barrel and the interior of the inner barrel are cleaned through water flow, so that cleaning of the pollution gas is guaranteed, and timely cleaning of the interior of the outer barrel and the interior of the inner barrel is also guaranteed.

Owner:邓香

Auxiliary device for producing computer processor mainboard

InactiveCN114393529AUnblock effectAchieve clamping and fixing effectWork holdersMachiningIndustrial engineering

The invention discloses an auxiliary device for producing a computer processor mainboard in the technical field of computer mainboard production equipment.The auxiliary device comprises a bottom frame, a machining table is fixedly installed at the top of the bottom frame, and a fixing box is fixedly installed on the front side of the interior of the bottom end of the machining table; and side boxes located on the two sides of the fixed box are fixedly installed in the bottom end of the machining table, and the bottoms of the fixed box and the side boxes are all located below the machining table. By arranging the telescopic mechanism, the fixed plate, a second movable clamp, a fixed clamp and a movable mechanism, due to rotation of a lead screw, a piston plate can move downwards in a fixed box, and then the sealing effect of the two sides of the piston plate on the interiors of the two side boxes can be relieved; at the moment, a water source in the side box can continuously enter the fixed box, and along with continuous reduction of the water pressure in the side box, a flexible spring which is originally in a compressed state can push a moving block to move.

Owner:DEZHOU VOCATIONAL & TECHN COLLEGE

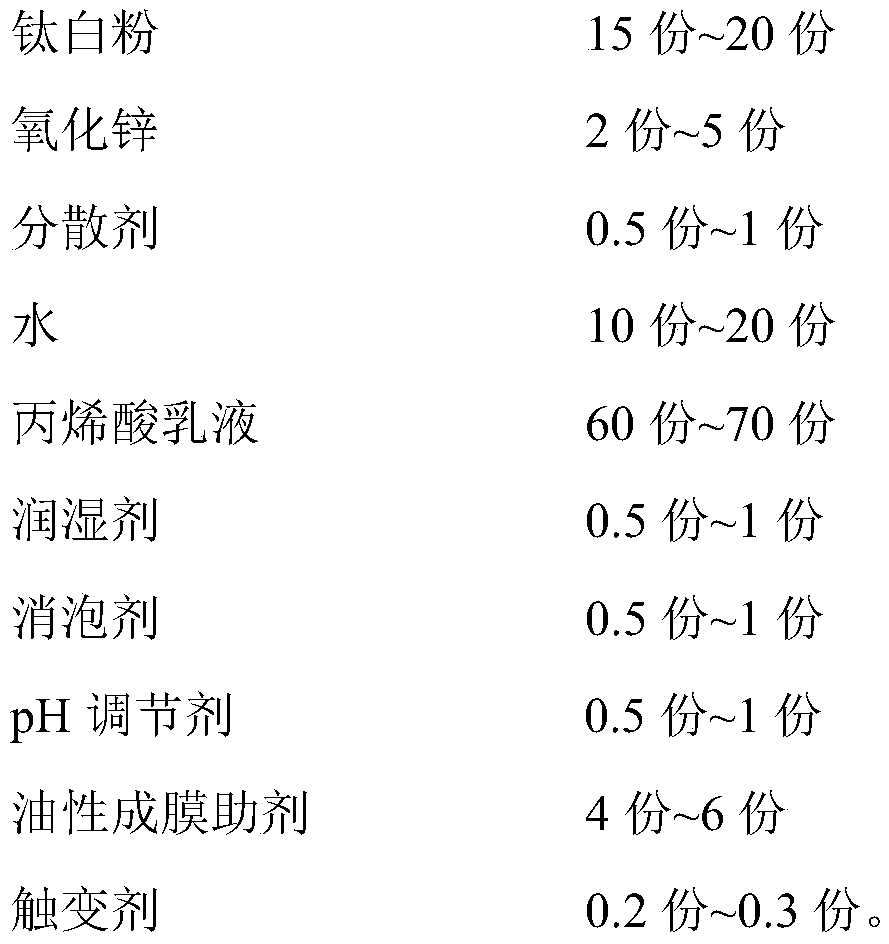

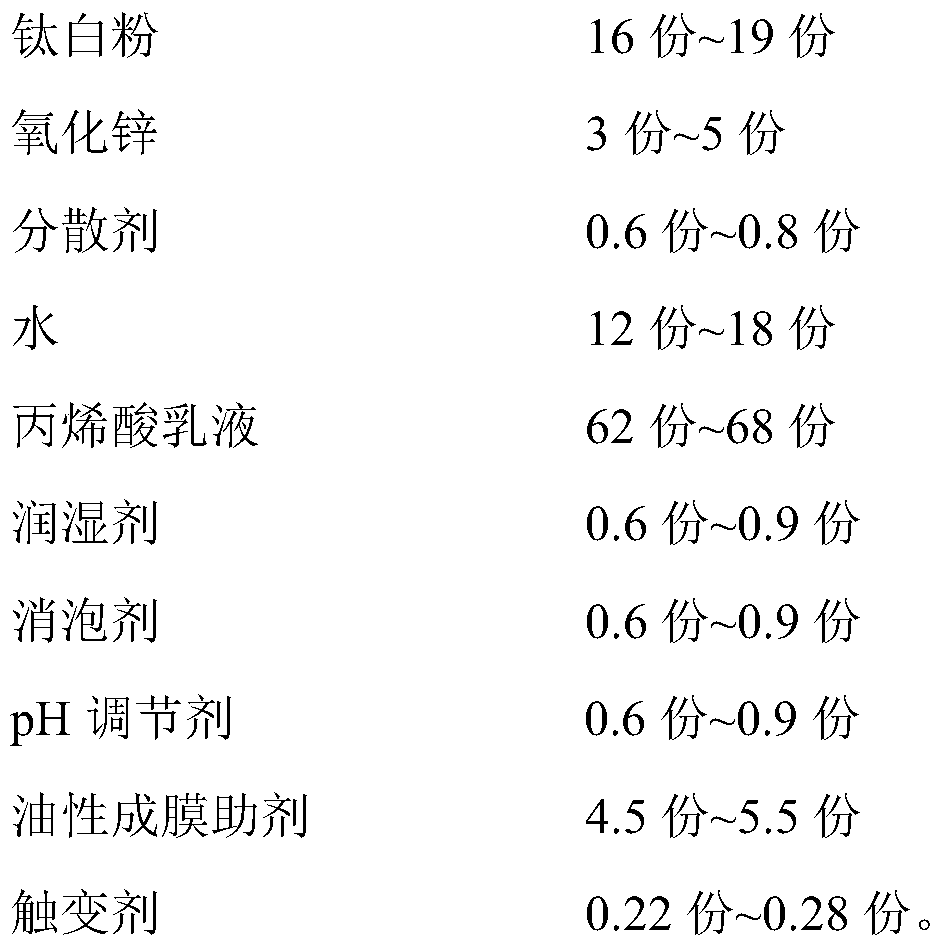

Waterborne pigment-sealing primer coating and preparation method thereof

The invention relates to the technical field of coatings, and concretely relates to a waterborne pigment-sealing primer coating and a preparation method thereof. The waterborne pigment-sealing primercoating comprises titanium dioxide, zinc oxide, a dispersing agent, water, an acrylic emulsion, a wetting agent, a defoaming agent, a pH regulator, an oily coalescing agent and a thixotropic agent. Acid substances represented by tannic acid, pigments and the like are contained in raw materials, so the coating has strong hydrophilicity and color, and floats on the surface of a paint film along withmoisture in the drying process of the paint film, so that metal oxide zinc oxide is introduced into the formula system, acidic substances are locked in a bottom-layer paint film by utilizing an acid-base reaction mechanism, and the disadvantage of discoloration of the water-based paint film is thoroughly solved. In addition, a zinc salt generated by the reaction is stable, has a low solubility, can stably exist in an aqueous system and has no influence on a final primer coating film. The waterborne pigment-sealing primer coating has the advantages of good pigment sealing effect, no use of a transparent sealing primer, simplification of the decoration process, and good coating effect.

Owner:东莞大宝化工制品有限公司

A one-way anti-backflow pipeline ball valve

ActiveCN112253784BEasy to assembleLow costPlug valvesOperating means/releasing devices for valvesEngineeringLeft valve

Owner:CHINA VALVE HLDG (GRP) CO LTD

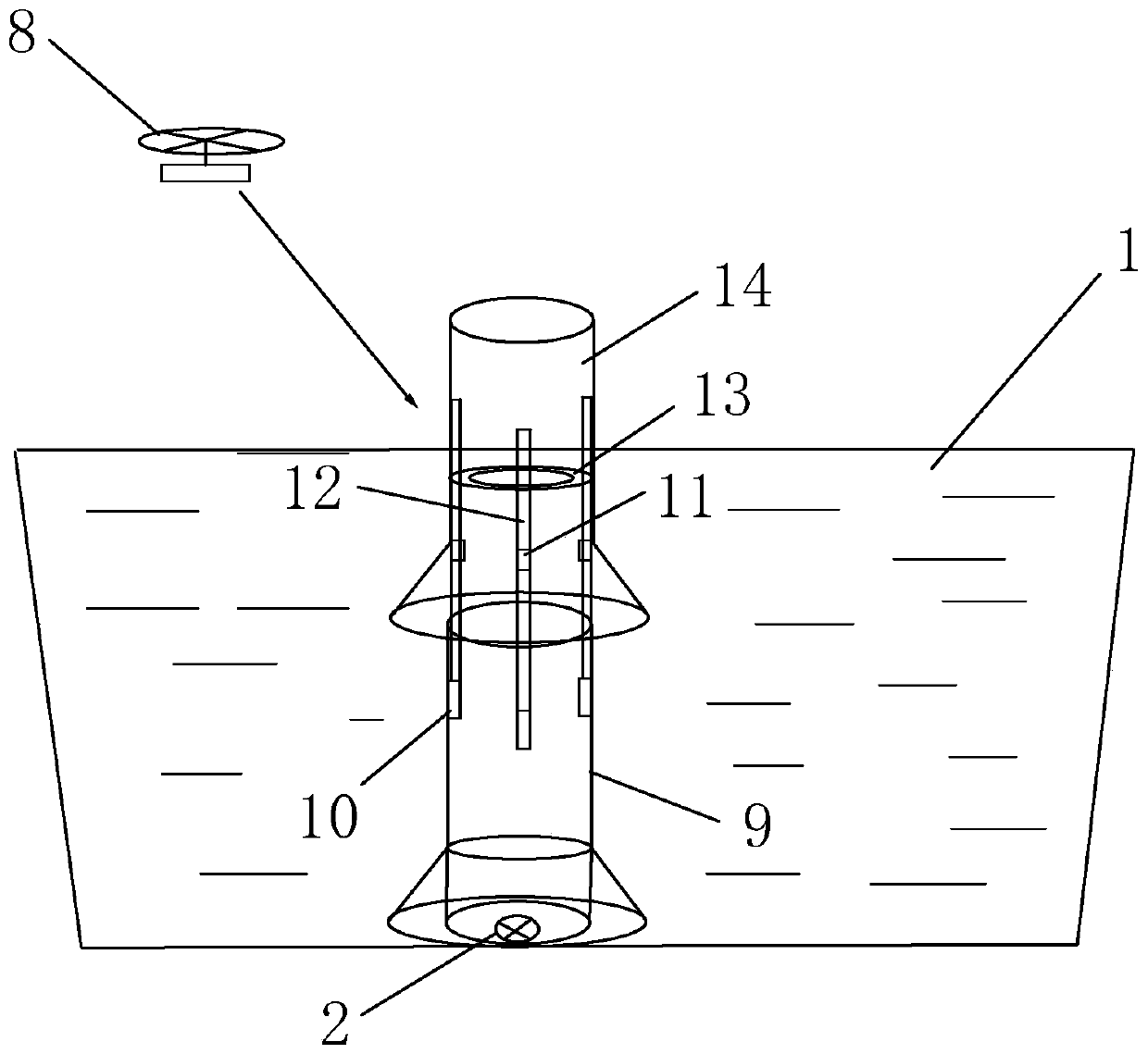

Ocean mud flat environment sampling system and method

PendingCN114544245ABottom collection and bagging are convenientSolve the inconvenience of taking mudGeneral water supply conservationWithdrawing sample devicesCollection systemEnvironmental engineering

The invention relates to an ocean mud flat environment sampling system and method, the system comprises a substrate collection system and a water sample collection system, the substrate collection system comprises a mud separation barrel and a mud collection bag, the mud collection bag is arranged in the mud separation barrel, the bottom of the mud collection bag is open, the top of the mud collection bag is closed, and the bottom opening of the mud collection bag is turned over outwards to wrap the outer side of the periphery of the bottom of the mud separation barrel; the water sample collection system comprises a mud separation barrel and a water collector, the water collector is arranged in the mud separation barrel and comprises a water collection barrel, more than one circle of water inlet holes are formed in the position, close to the bottom, of the side wall of the water collection barrel, the water collection barrel is sleeved with a closed ring, and the closed ring is located above the water inlet holes and can move downwards to block the water inlet holes. The method comprises the following steps: simultaneously placing a mud collection bag and a water collector in a mud separation barrel, and simultaneously collecting a substrate and a water sample by the water collector positioned above the mud collection bag, or independently placing the mud collection bag and the water collector in the mud separation barrel, and respectively collecting the substrate and the water sample. The device is ingenious and flexible in structural design, and a substrate and water sample collecting device controllable by a single person is achieved.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com