A kind of manufacturing method of screw rod for food processing machine and screw rod thereof

The technology of a food processing machine and a production method, which is applied to the screw production method and the screw field thereof, can solve the problems of long screw production cycle, large screw weight, and influence on the yield of finished products, and achieves saving of production materials, high yield of finished products, and convenience for mass production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

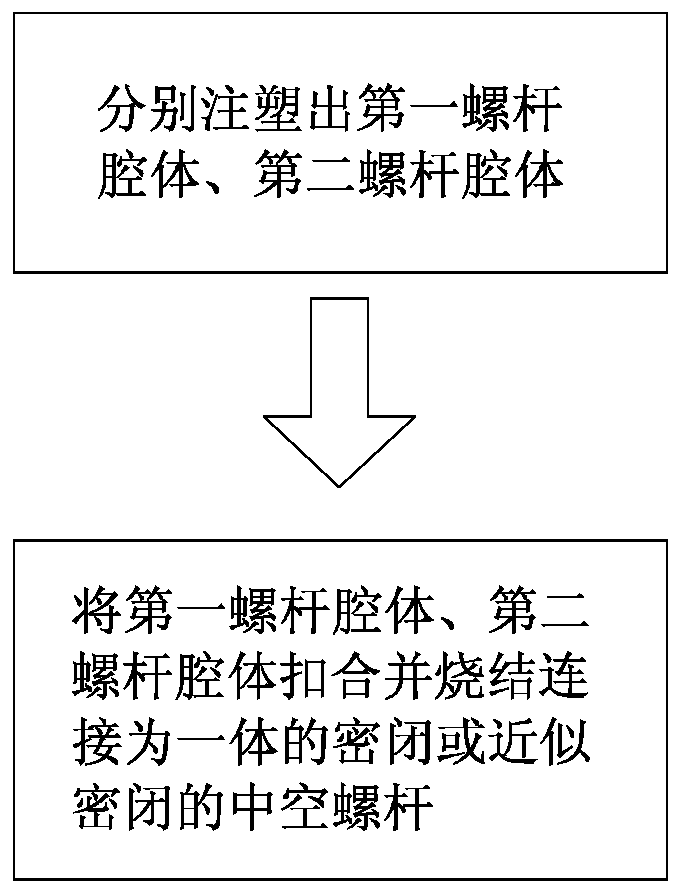

Method used

Image

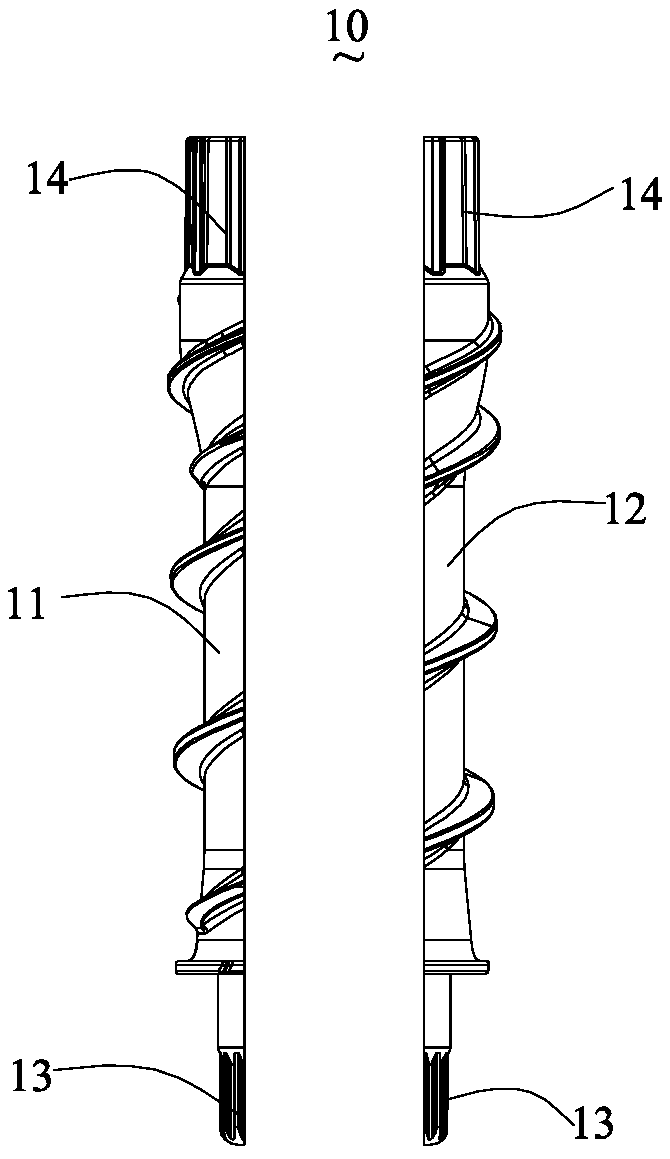

Examples

Embodiment approach 2

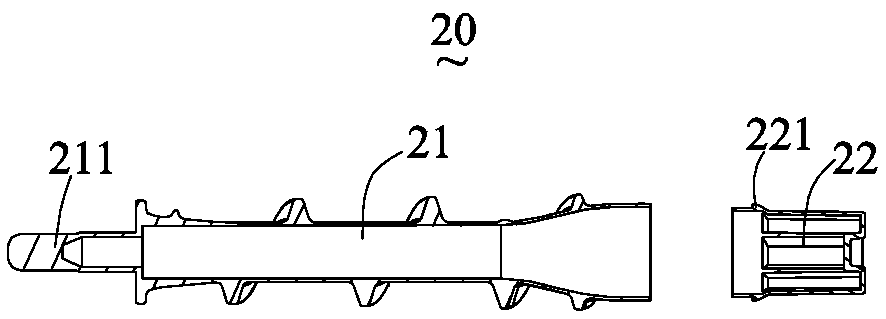

[0039] see image 3The second preferred embodiment of the screw manufacturing method for food processing machines is different from Embodiment 1 in that: the first screw cavity 21 and the second screw cavity 22 are tubular structures in which the hollow screw 20 is radially separated , the first screw cavity 21 and the second screw cavity 22 are radially connected and sintered. In this way, the length of radial sintering is relatively short, which makes the sintering process more convenient and simple.

[0040] In this embodiment, the first screw cavity 21 is a threaded hollow screw body, and the first screw cavity 21 also includes a motor shaft connecting portion 211 of a food processor, and the second screw cavity That is, the end cover of the food processor is fitted with the fixed part.

[0041] In this embodiment, the fitting and fixing part of the end cover is further provided with a clamping platform 221 , and the fixing and fixing part of the end cover extends into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com