Waterborne pigment-sealing primer coating and preparation method thereof

A pigment and white base technology, which is applied in the field of water-based pigment-sealed white base paint and its preparation, can solve problems such as unsatisfactory effects, discoloration of coating films, and material spit out, and achieve the goals of reducing the floating of pigments, solving discoloration, and stabilizing solubility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

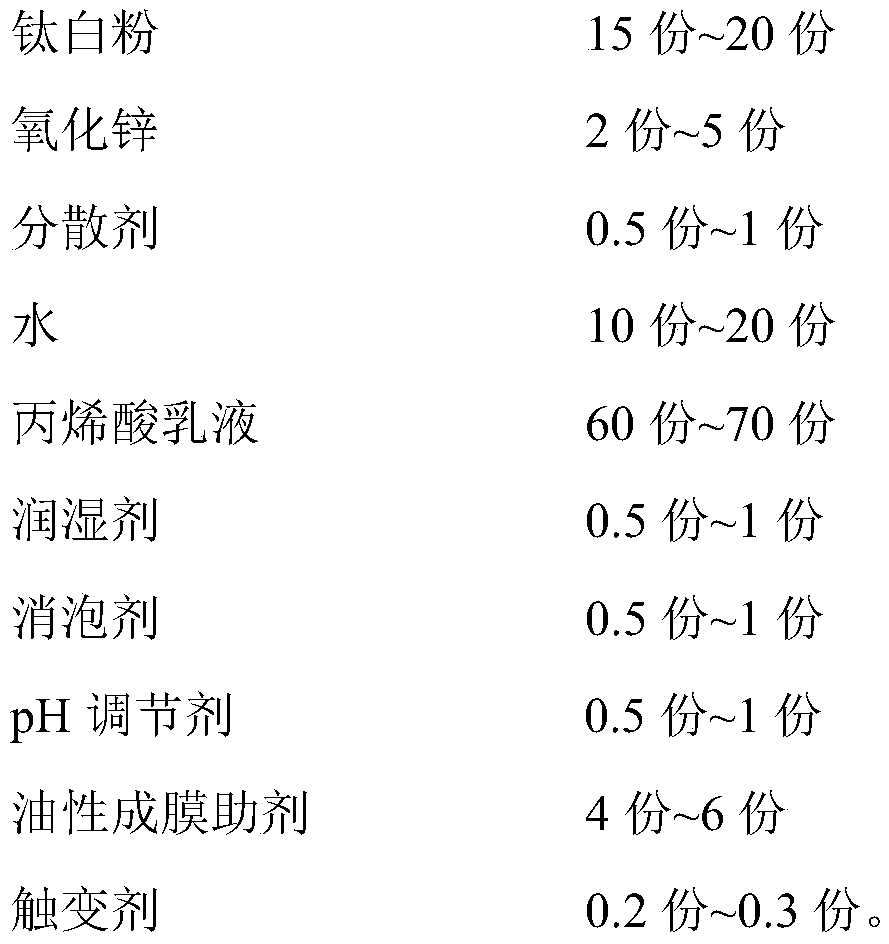

[0036] A water-based pigment-sealed white base paint, which includes the following raw materials in parts by weight:

[0037]

[0038]

[0039] Wherein, the oily film-forming aid is a composition of oily film-forming aid DPNB and oily film-forming aid TPNB at a mass ratio of 1:1.

[0040] Among them, the dispersant is BYK-190 dispersant; the acrylic emulsion is Dow EXP-6037 acrylic emulsion; the wetting agent is BYK-349 wetting agent; the defoamer is TEGO FOAMEX 822 defoamer; the pH regulator is SOLVAY AN130pH Regulator; thixotropic agent is Dow RM-12W thixotropic agent.

[0041] The preparation method of above-mentioned a kind of water-based pigment-sealed white primer, it may further comprise the steps:

[0042] Step 1. Prepare the first mixture: Stir and mix the titanium dioxide, zinc oxide, dispersant and a part of the water at a speed of 1000 rpm for 12 minutes, then grind to a fineness of ≤25 μ to obtain the first mixture;

[0043] Step 2. Prepare the second mixt...

Embodiment 2

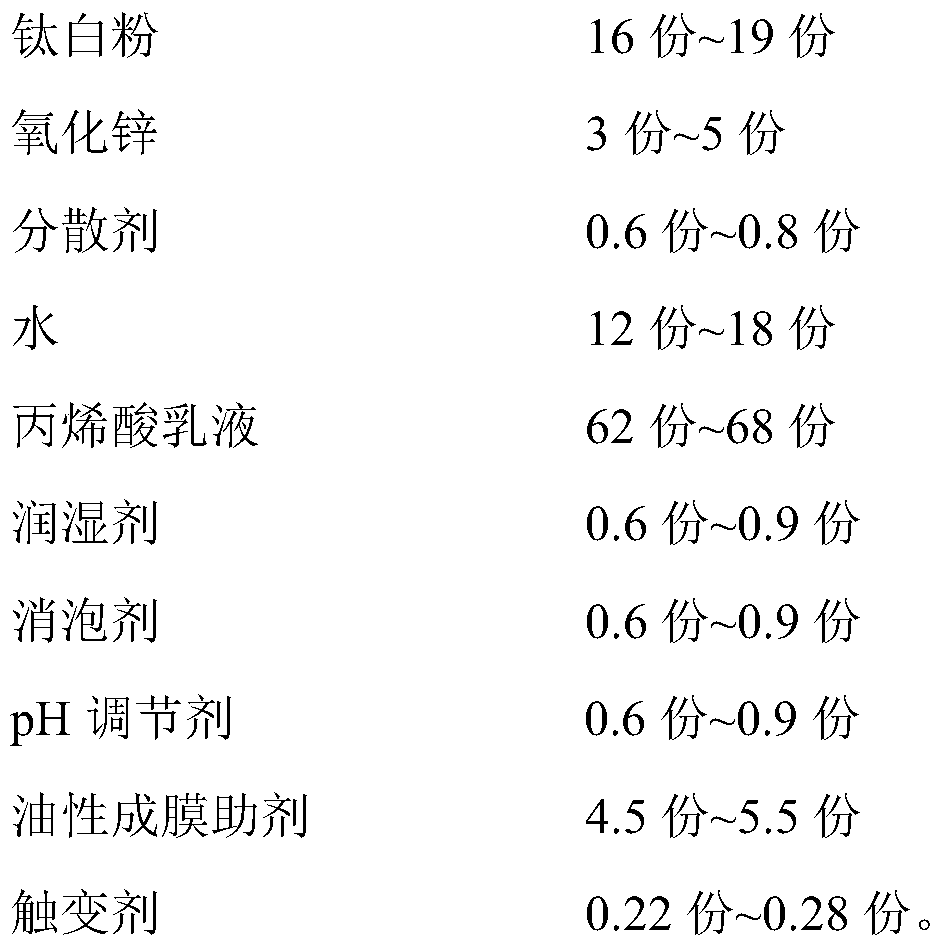

[0048] A water-based pigment-sealed white base paint, which includes the following raw materials in parts by weight:

[0049]

[0050]

[0051] Wherein, the oily film-forming aid is a composition of oily film-forming aid DPNB and oily film-forming aid TPNB at a mass ratio of 0.5:1.5.

[0052] Among them, the dispersant is BYK-190 dispersant; the acrylic emulsion is Dow EXP-6037 acrylic emulsion; the wetting agent is BYK-349 wetting agent; the defoamer is TEGO FOAMEX 822 defoamer; the pH regulator is SOLVAY AN130pH Regulator; thixotropic agent is Dow RM-12W thixotropic agent.

[0053] The preparation method of above-mentioned a kind of water-based pigment-sealed white primer, it may further comprise the steps:

[0054] Step 1. Prepare the first mixture: Stir and mix the formulated amount of titanium dioxide, zinc oxide and dispersant, and a part of water at a speed of 900 rpm for 15 minutes, and then grind to a fineness of ≤25 μ to obtain the first mixture;

[0055] Ste...

Embodiment 3

[0060] A water-based pigment-sealed white base paint, which includes the following raw materials in parts by weight:

[0061]

[0062]

[0063] Wherein, the oily film-forming aid is a composition of oily film-forming aid DPNB and oily film-forming aid TPNB at a mass ratio of 1.5:0.5.

[0064] Among them, the dispersant is BYK-190 dispersant; the acrylic emulsion is Dow EXP-6037 acrylic emulsion; the wetting agent is BYK-349 wetting agent; the defoamer is TEGO FOAMEX 822 defoamer; the pH regulator is SOLVAY AN130pH Regulator; thixotropic agent is Dow RM-12W thixotropic agent.

[0065] The preparation method of above-mentioned a kind of water-based pigment-sealed white primer, it may further comprise the steps:

[0066] Step 1. Prepare the first mixture: Stir and mix the titanium dioxide, zinc oxide, dispersant and a part of the water at a speed of 1100 rpm for 10 minutes and grind to a fineness of ≤25 μ to obtain the first mixture;

[0067] Step 2. Prepare the second mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com