Spray coating system for environmentally-friendly water-based door sheet

A door panel, water-based technology, applied in the field of spraying system, can solve the problems of high labor intensity, complicated spraying process, harmful to physical and mental health, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

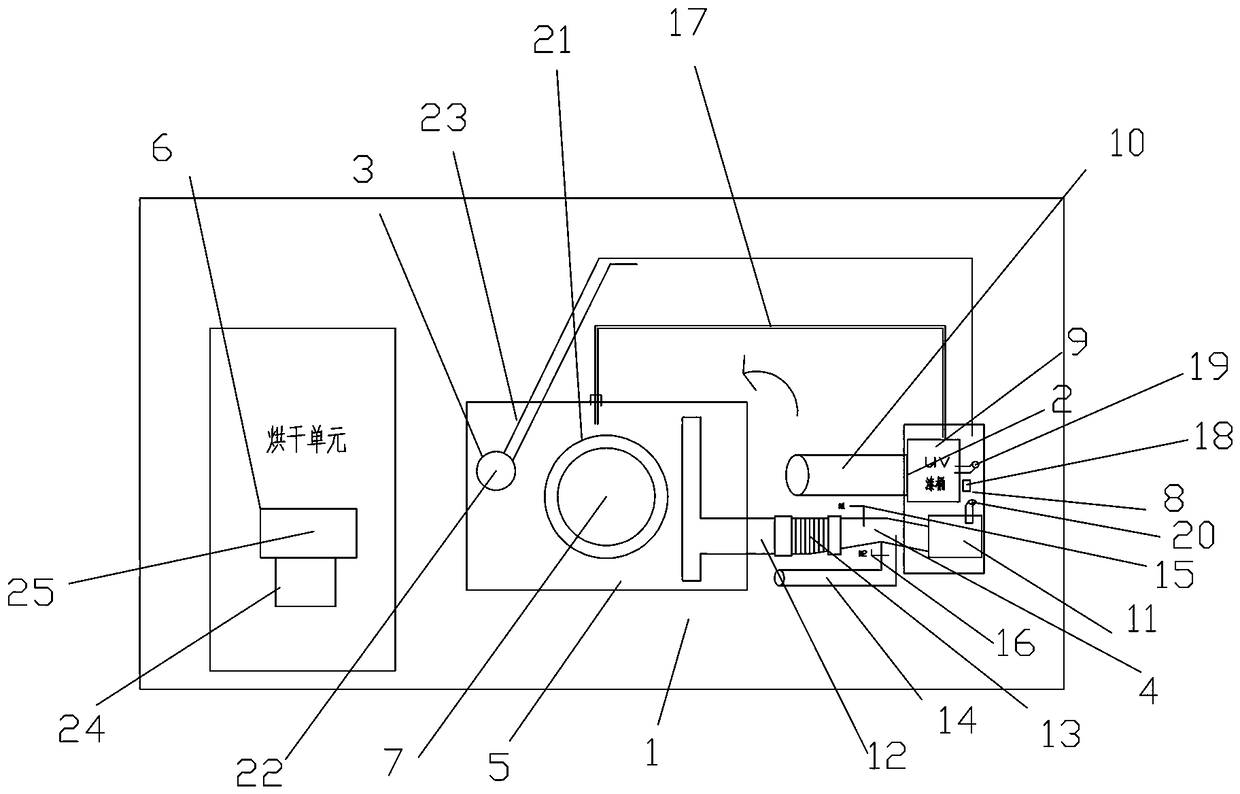

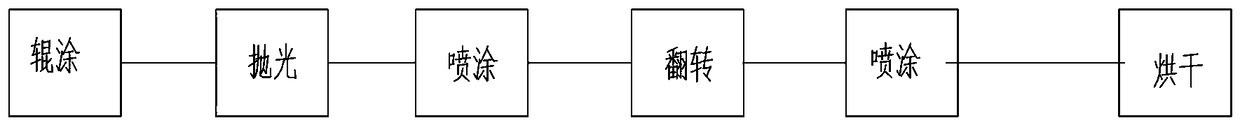

[0024] like figure 1 , figure 2 As shown, the spraying system of the environmental protection water-based door panel provided by the present invention includes a working platform 1 and a roller coating unit 2, a polishing unit 3, a spraying unit 4, a turning unit 5 and a drying unit 6 arranged on the working platform 1; the described The working platform 1 includes a lifting platform 7 and a console 8, and the above-mentioned console 8 is arranged on one side of the lifting platform 7. On the lifting platform 7, a rotary suction cup 21 that can tightly suck the door panel and rotate 360° is sleeved; The roller coating unit 2 includes a first paint bucket 9 and a first paint spray gun 10 penetrating the side of the console 8 to connect the first paint bucket 9; the above-mentioned polishing unit 3 includes a polishing machine 22 and a mechanical gripper 23 that drives the polishing machine 22 to move, The manipulator 23 is connected to the console 8; the above-mentioned spray...

Embodiment 2

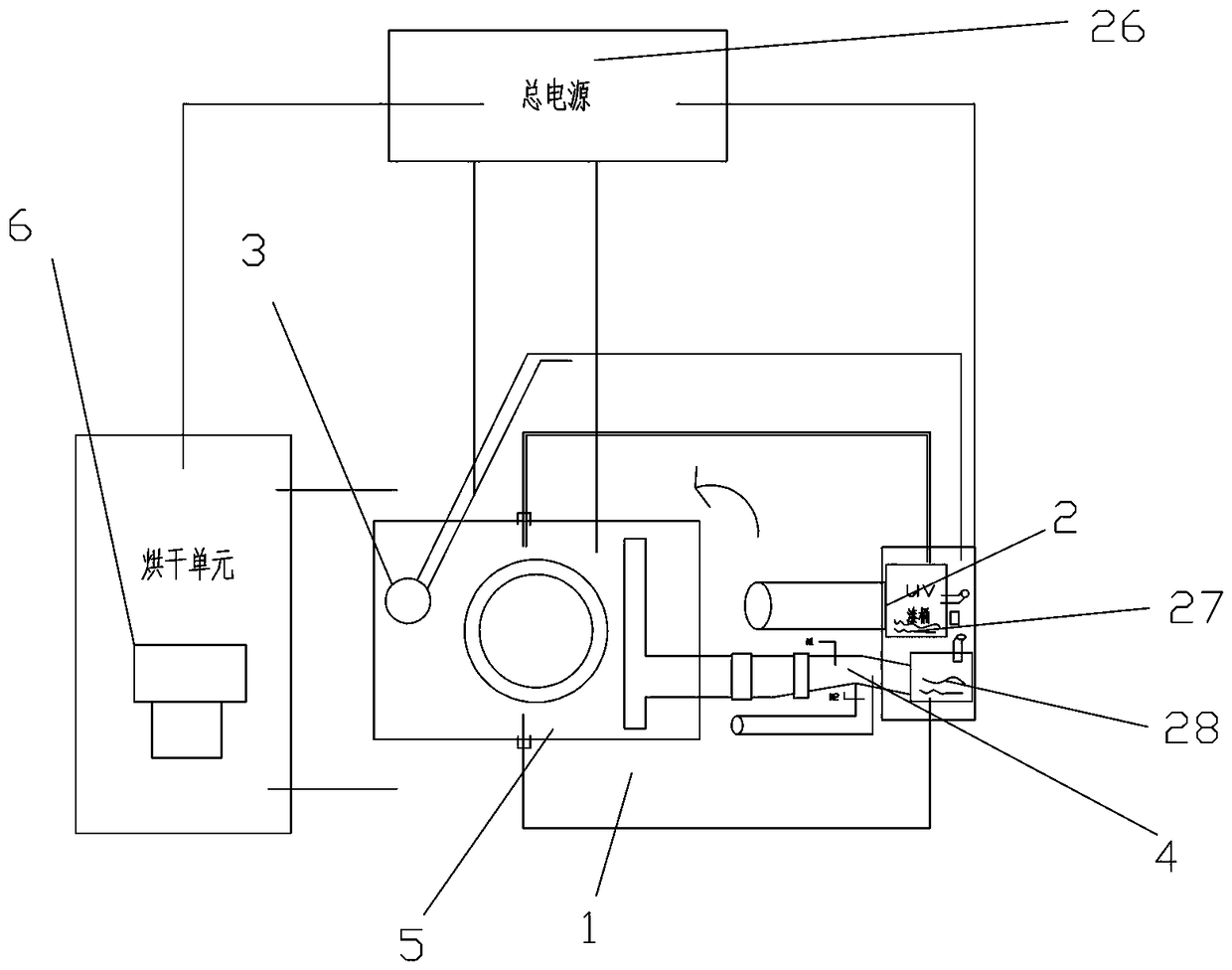

[0027] like image 3 As shown, the general structure of the spraying system for environmental protection water-based door panels provided in this embodiment is the same as that of Embodiment 1, except that in order to drive each machine to work, the working platform 1 is connected to a driving power source 26, and the driving power source 26 Drive the roller coating unit 2, the polishing unit 2, the spraying unit 4, the turning unit 5 and the drying unit 6 to work; in order to close the surface of the panel, UV paint 27 is installed in the first paint bucket 9; The second paint bucket 11 is filled with water-based paint 28 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com