Electrode leading-out terminal

An electrode lead-out terminal and electrode lead-out technology, which is applied to electric heating devices, electrical components, heating through discharge, etc., can solve the problems of electrode lead-out and sealing without a good solution, so as to increase the contact area and improve the contact area. , Good effect of large area transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

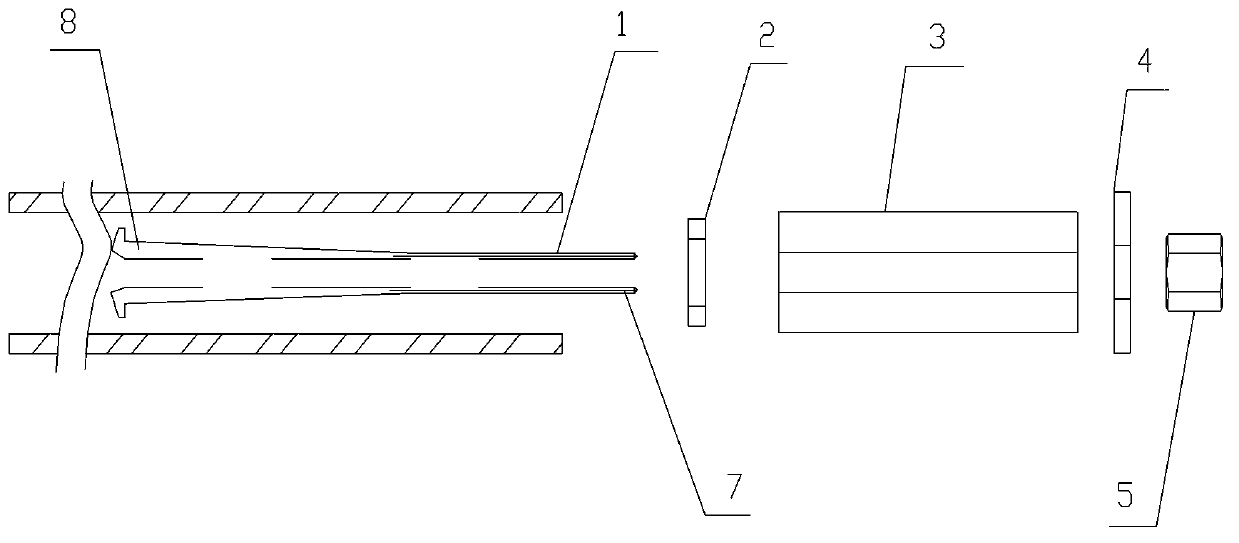

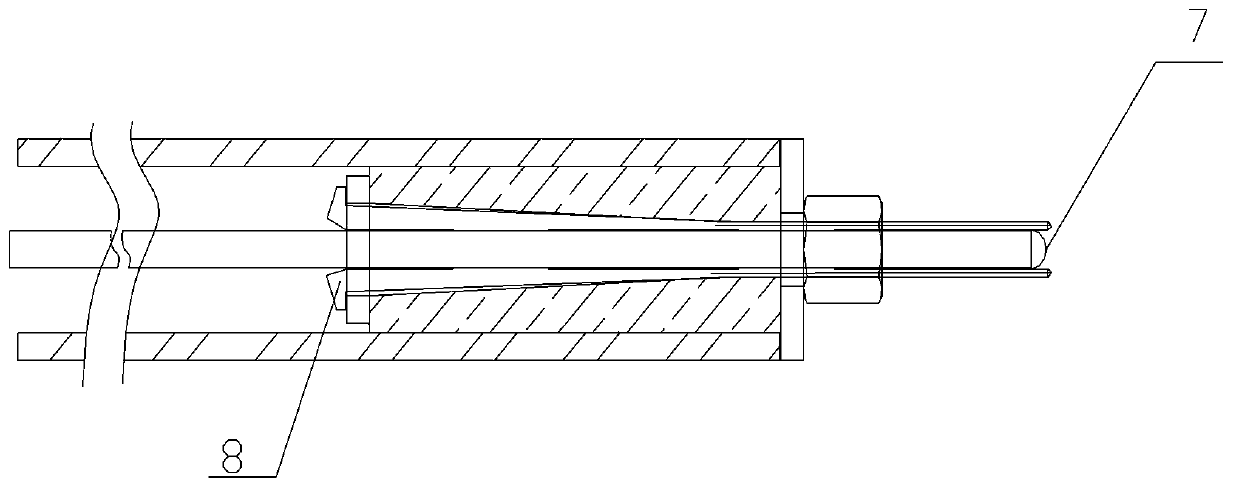

[0014] An embodiment of the present invention provides an electrode lead-out terminal, including: an electrode lead-out shell, a hollow expansion bolt, a first annular gasket, a second annular gasket, an annular expansion body, a nut, and a wire;

[0015] The expansion bolt passes through the first annular gasket, the annular expansion body, the second annular gasket, and the nut in turn, and is threadedly connected with the nut; the wire passes through the expansion bolt ;

[0016] The expansion end of the expansion bolt is inside the electrode lead-out casing, and the end of the expansion bolt connected to the nut is outside the electrode lead-out casing;

[0017] The expansion end is provided with an extension edge, and in the direction from the expansion end to the end of the expansion bolt connected to the nut, the extension edge, the first annular gasket, the annular expansion body, the first The two ring gaskets and the nuts are in close contact with each other in turn...

Embodiment 2

[0021] An electrode lead-out terminal, such as figure 1 , 2 As shown: including the electrode lead-out casing, a hollow expansion bolt 1 is provided inside the electrode lead-out casing. The expansion bolt 1 is made of copper, iron, or stainless steel. One end of the expansion bolt 1 is an expansion end 8. The expansion end 8 presents a multi-lobe structure, which can be understood as splitting the expansion bolt 1 into multiple lobes in the axial direction. All the lobes can be tightly entangled or there may be gaps between adjacent lobes, depending on the expansion bolt 1 inserted into the hollow. The thickness of the wire. The other end 7 of the expansion bolt 1 is provided with threads, through which the expansion bolt 1 is connected with the nut 5 and is located outside the electrode lead-out casing. The expansion end 8 of the expansion bolt 1 is provided with an extension edge. Due to the extension edge, the expansion end 8 is trumpet-shaped. In the direction from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com