Bath foam storage and adjustment type bath ball and production process thereof

A production process and technology of bath balls, applied in the field of bath balls and their production process, can solve the problems of uncontrollable bath liquid output, etc., and achieve the effects of high speed, low cost, and liquid leakage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further illustrated by the following examples:

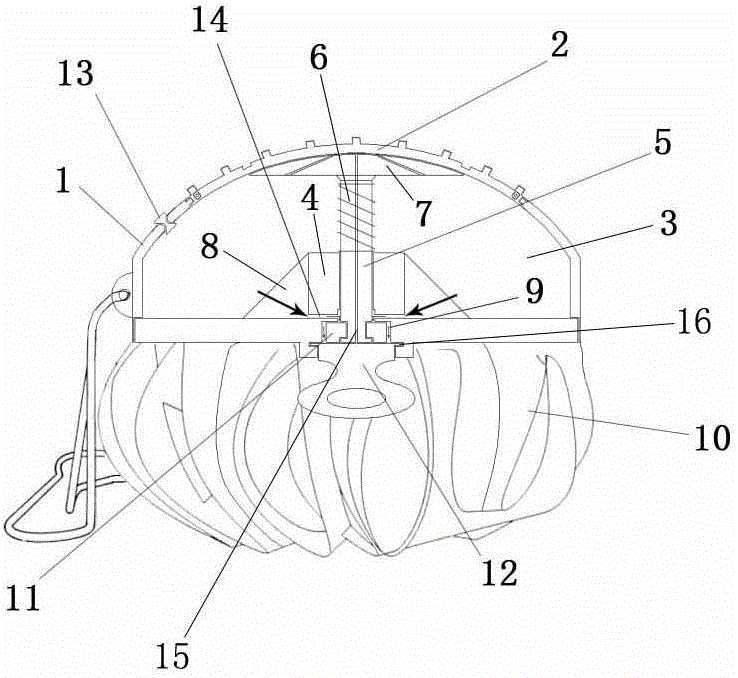

[0032] refer to figure 1 with figure 2 , a bath ball capable of storing and adjusting bath liquid, comprising a handle and a shower flower 10, wherein the shower flower 10 is bundled under the handle by winding and tightening.

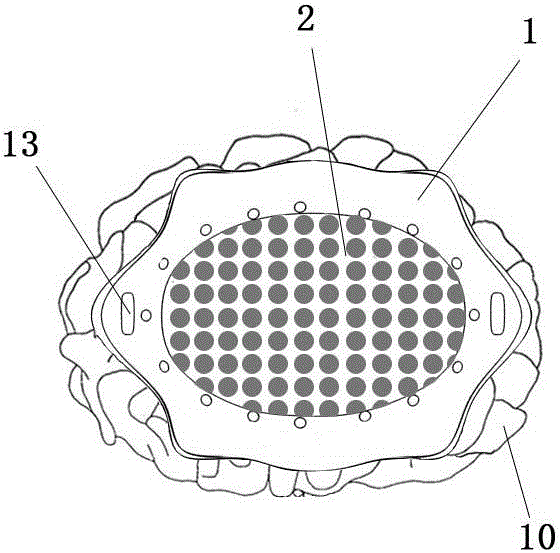

[0033] Such as figure 1 As shown, the bottom of the handle is an open hard container 1, and the opening of the hard container 1 is closed by an arc-shaped soft top cover 2 to form a cavity 3, wherein the hard container 1 is formed from the top The shell and the shell base are composed, and the bottom of the shell includes a support seat 4 and a reinforcing rib 8 integrally formed on it. The material is hard glue made of ABS resin, and the material of the soft top cover 2 is made of TPR resin. soft glue. combine figure 2 As shown, the rigid container 1 is provided with a liquid inlet hole, and the liquid inlet hole is closed by a pluggable silicone sealing plug 13 fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com