A plastic film wrapping device

A technology of plastic film and equipment, applied in the field of plastic film wrapping equipment, can solve the problems of labor and time consumption, reduce enterprise profit, low efficiency, etc., and achieve the effect of reducing manual operation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

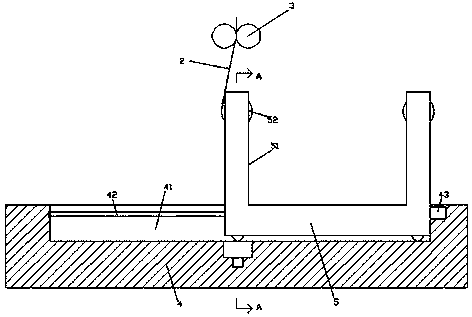

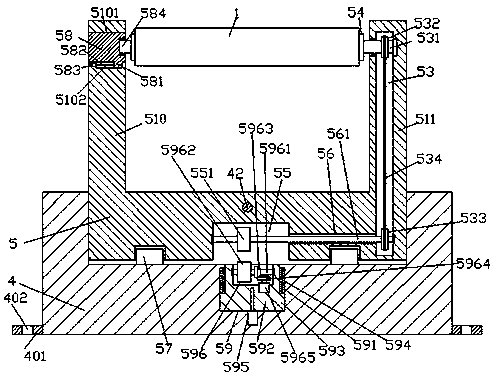

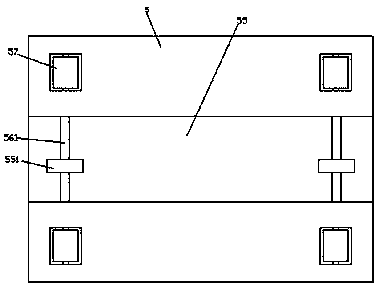

[0024] Such as Figure 1-Figure 6 As shown, a plastic film wrapping device of the present invention includes a frame 4 and clamping wheels 3 arranged above the top of the frame 4 and arranged opposite to each other left and right, and the front and rear sides of the frame 4 are fixedly equipped with fixing frames 401 , the fixing frame 401 is provided with a fixing hole 402, and the fixing hole 402 is used for screwing in so as to fix the frame 4. The chassis 5 is connected in translation in the groove 41. A first slide chamber 59 is provided at the center of the bottom of the first guide groove 41. A second guide groove 591 is provided opposite to the front and rear sides of the first slide chamber 59. The first guide groove 591 The slide cavity 59 is provided with a first slide frame 592, and the front and rear sides of the bottom of the first slide frame 592 are respectively provided with a first guide frame 593 that is jacked into the second guide grooves 591 on the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com