Welding equipment convenient to move

It is a welding equipment and a technology that is convenient to move. It is used in the transportation of filamentous materials, thin material processing, transportation and packaging. It can solve the problems of reducing corporate profits, consuming manpower and time, and complicated procedures, improving work efficiency and reducing The effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

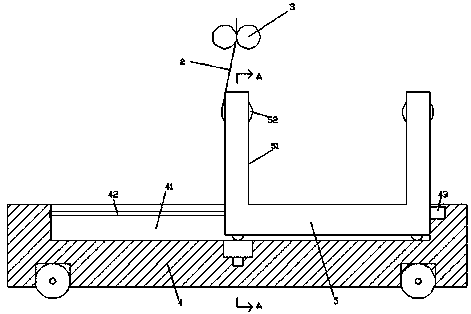

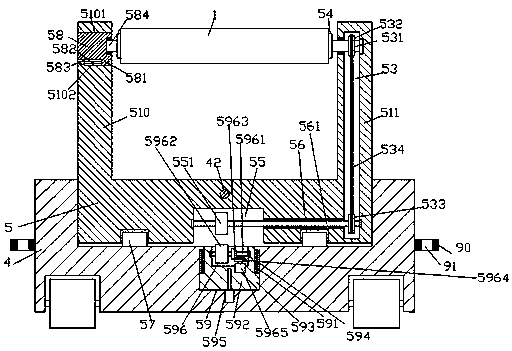

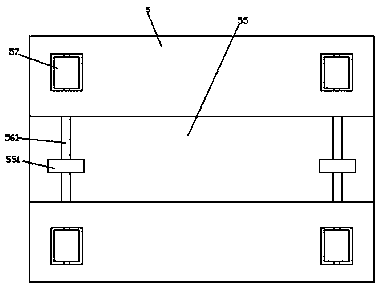

[0025] Such as Figure 1-Figure 6 As shown, a convenient mobile welding device of the present invention includes a frame body 4 and a gripper 3 arranged above the top of the frame body 4 and oppositely arranged left and right. The bottom of the frame body 4 is provided with a rotating wheel 401, so that The rotating wheel 401 is used to conveniently move the position of the frame body 4, the frame body 4 is provided with a first guide groove 41, and the first guide groove 41 is movable and connected to the bottom frame 5, and the first guide groove 41 is movable and connected to the bottom frame 5. The center position of the bottom of the guide groove 41 is provided with a first sliding groove 59, and the front and rear sides of the first sliding groove 59 are equally provided with a second guiding groove 591, and the first sliding groove 59 is provided with a first Sliding block 592, the front and rear sides of the bottom of the first sliding block 592 are respectively provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com