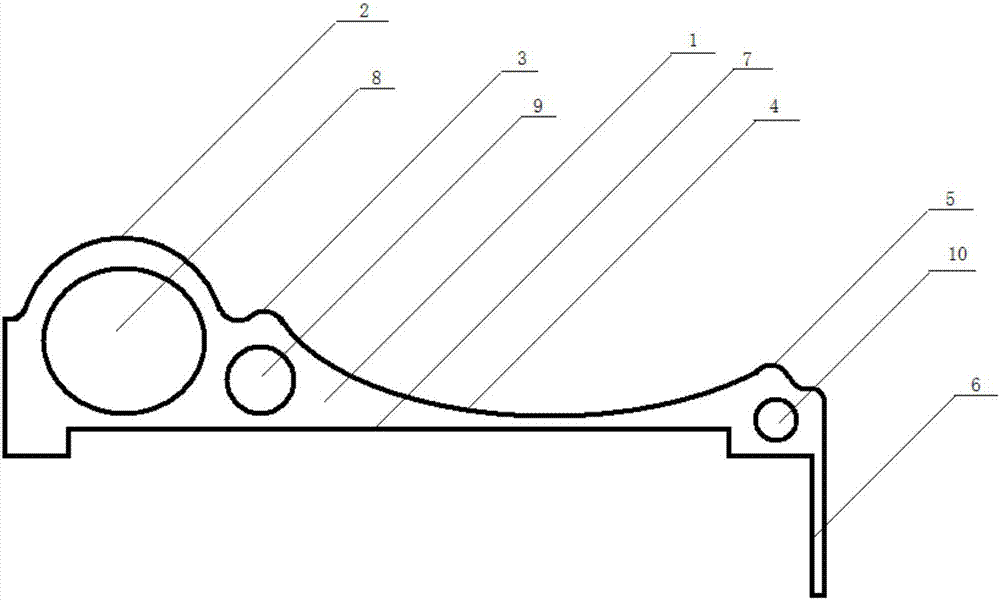

Hollow edge shrinkage line with semicircular projection and large concave arc

A concave arc and line technology, which is applied in the field of edge trimming, can solve the problems of affecting the overall effect and aesthetics of decoration, poor firmness, affecting aesthetics, etc., to avoid the danger of slipping, reduce weight, and increase aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

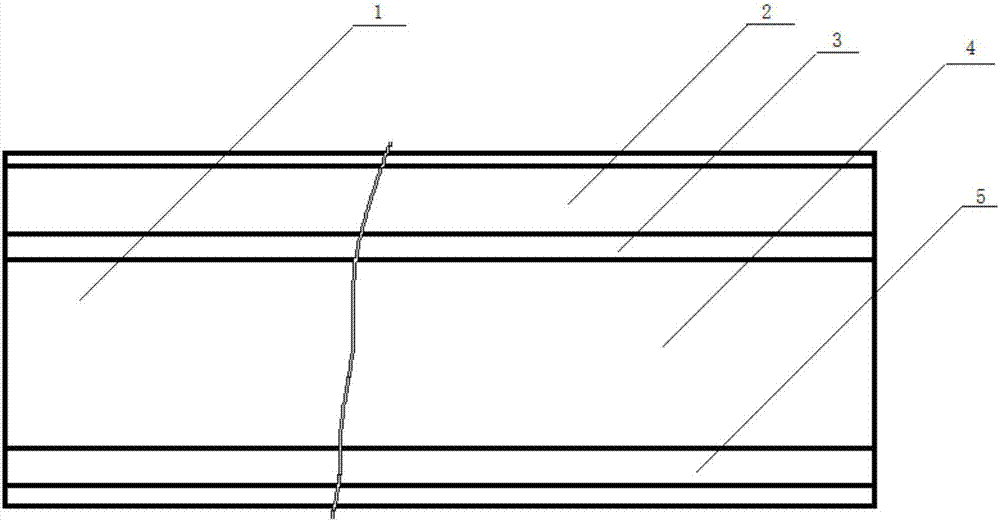

[0017] Embodiment 1: A hollow edge-receiving line with semicircular protrusions and large concave arcs. The line body 1 is in the shape of a thin, flat, long strip. The bottom of the line body 1 is provided with a bottom surface 7 for storing and applying adhesive. The bottom surface 7 The right end of the right end is provided with the edge-receiving card strip 6 that is used for edge-receiving lines, and the line body 1 is provided with large semicircular protrusion 2, middle protrusion 3, large concave arc 4 and side protrusion 5, two sides of large concave arc 4 The ends are respectively provided with a middle protrusion 3 and a side protrusion 5, the other side of the middle protrusion 3 is connected with a large semicircular protrusion 2, the inside of the line body 1 is provided with holes for heat insulation and material saving, and the surface of the line body 1 is sequentially arranged There are pattern coats, primer protection coats and wear coats.

Embodiment 2

[0018] Embodiment 2: A hollow edge-receiving line with semicircular protrusions and large concave arcs. The line body 1 is in the shape of a thin, flat, long strip. The bottom of the line body 1 is provided with a bottom surface 7 for storing and applying adhesive. The bottom surface 7 The right end of the right end is provided with the edge-receiving card strip 6 that is used for edge-receiving lines, and the line body 1 is provided with large semicircular protrusion 2, middle protrusion 3, large concave arc 4 and side protrusion 5, two sides of large concave arc 4 The ends are respectively provided with a middle protrusion 3 and a side protrusion 5, the other side of the middle protrusion 3 is connected with a large semicircular protrusion 2, the inside of the line body 1 is provided with holes for heat insulation and material saving, and the surface of the line body 1 is sequentially arranged There are pattern coats, primer protection coats and wear coats. The bottom surfac...

Embodiment 3

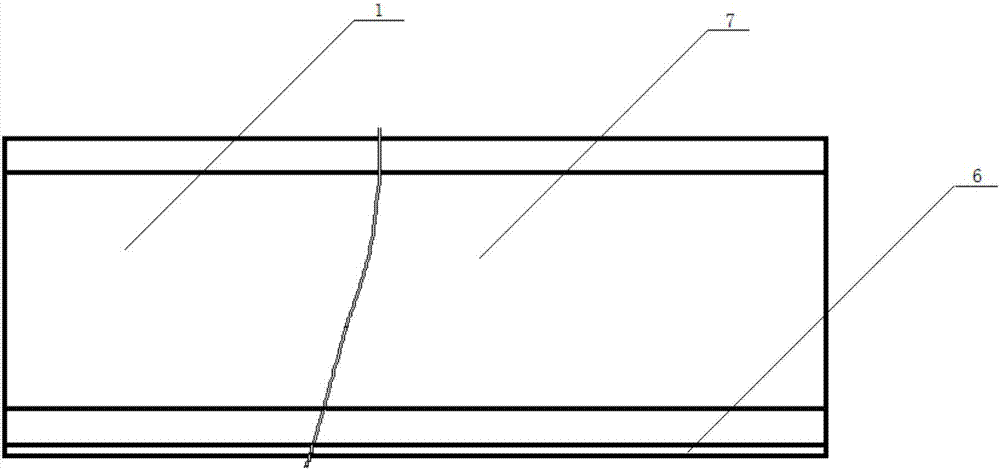

[0019] Embodiment 3: A hollow edge-receiving line with semicircular protrusions and large concave arcs. The line body 1 is in the shape of a thin, flat, long strip. The bottom of the line body 1 is provided with a bottom surface 7 for storing and applying adhesive. The bottom surface 7 The right end of the right end is provided with the edge-receiving card strip 6 that is used for edge-receiving lines, and the line body 1 is provided with large semicircular protrusion 2, middle protrusion 3, large concave arc 4 and side protrusion 5, two sides of large concave arc 4 The ends are respectively provided with a middle protrusion 3 and a side protrusion 5, the other side of the middle protrusion 3 is connected with a large semicircular protrusion 2, the inside of the line body 1 is provided with holes for heat insulation and material saving, and the surface of the line body 1 is sequentially arranged There are pattern coats, primer protection coats and wear coats. The bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com