An environmental chamber that simulates outdoor working conditions

A technology for working conditions and environmental chambers, which is applied in the field of building environment and equipment engineering, can solve the problems of low income, uniform airflow organization in the untestable area, and increase the initial investment and later maintenance costs of environmental chamber construction, so as to maintain uniformity and uniformity. Stable flow distribution and increased contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

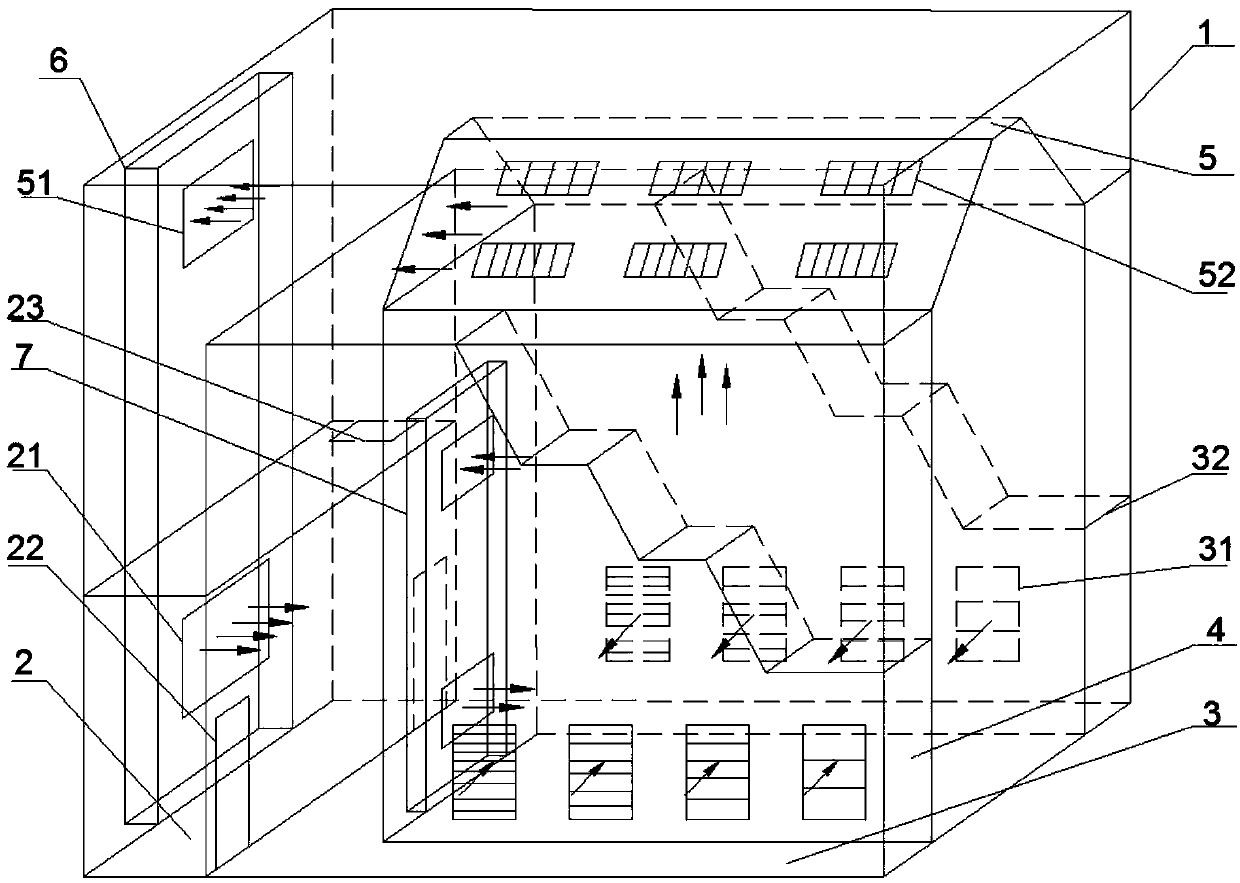

[0032] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

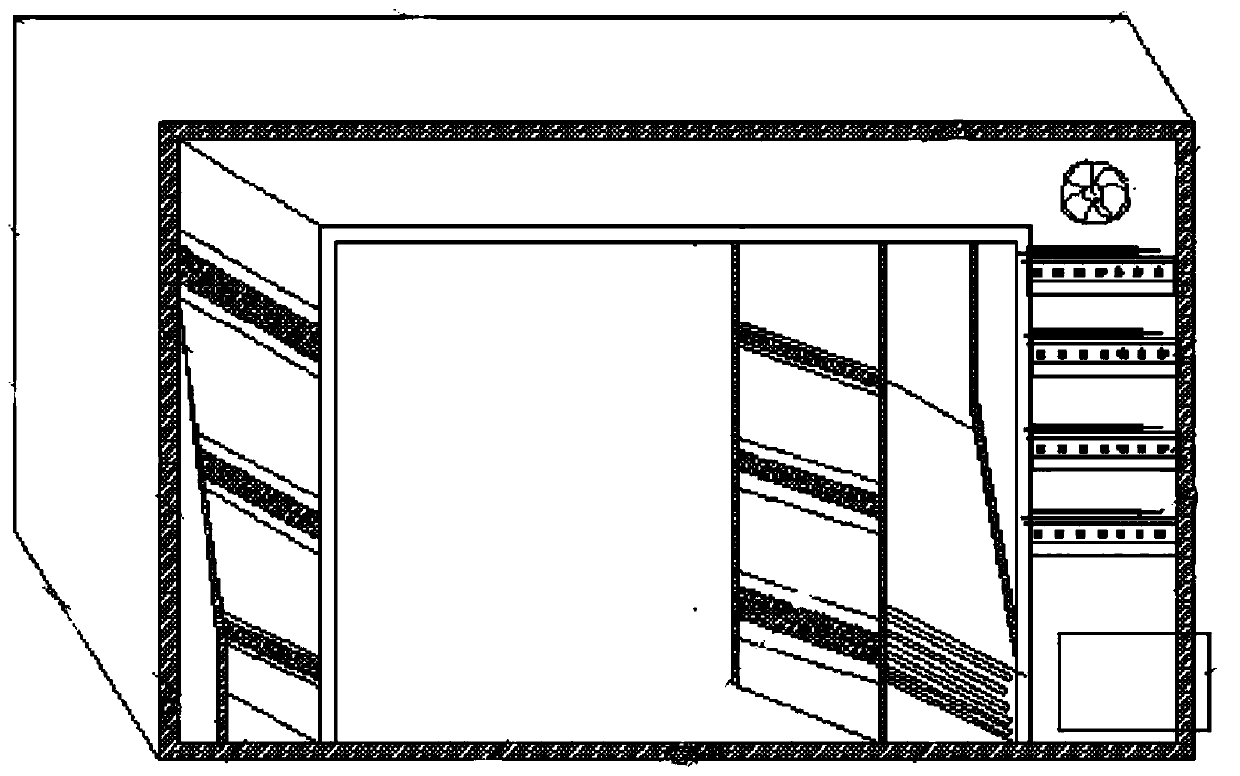

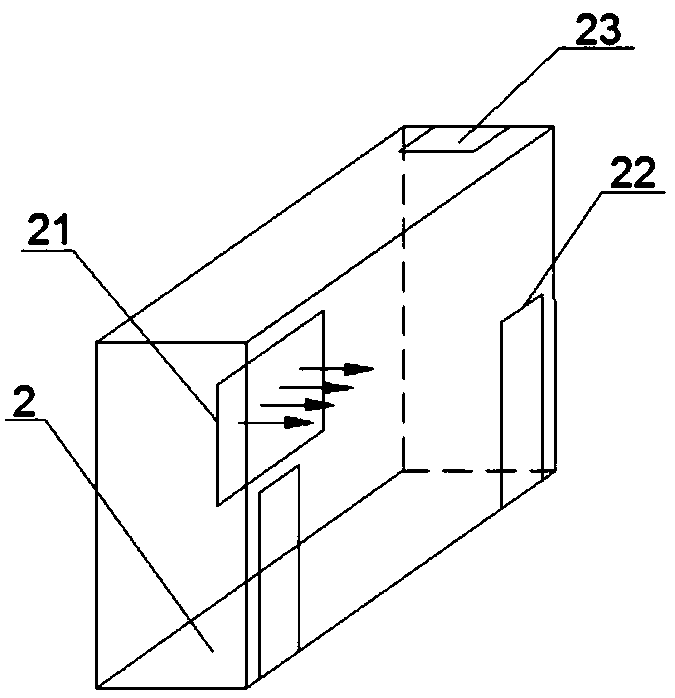

[0033] The environmental chamber for simulating outdoor working conditions in this embodiment includes a first air supply static pressure space 2 , a second variable section air supply static pressure space 3 , a test room 4 and a variable cross section return air static pressure space 5 . The first air-supply static pressure space 2 is provided with a first air-handling unit 6 , which includes an enclosure structure 1 , an air-supply port 21 , an air-supply door 22 and an inspection door 23 . The second air handling unit 7 is arranged outside the side partition of the test room 4, which includes a partition with air supply aluminum alloy louvers 31 and a double-pitched roof partition with return air aluminum alloy louvers 52. The air flow of the present invention is sent out from the air supply port 21 of the first air handling unit 6, first passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com