An environment chamber for performance testing of air-conditioning and refrigeration equipment

A technology for testing the environment and equipment performance, which is applied to the testing of machines/structural components, measuring devices, instruments, etc. It can solve problems such as instability, small space in the test environment cabin, unsatisfactory improvement effects and improved benefits, etc., to achieve Uniform distribution and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

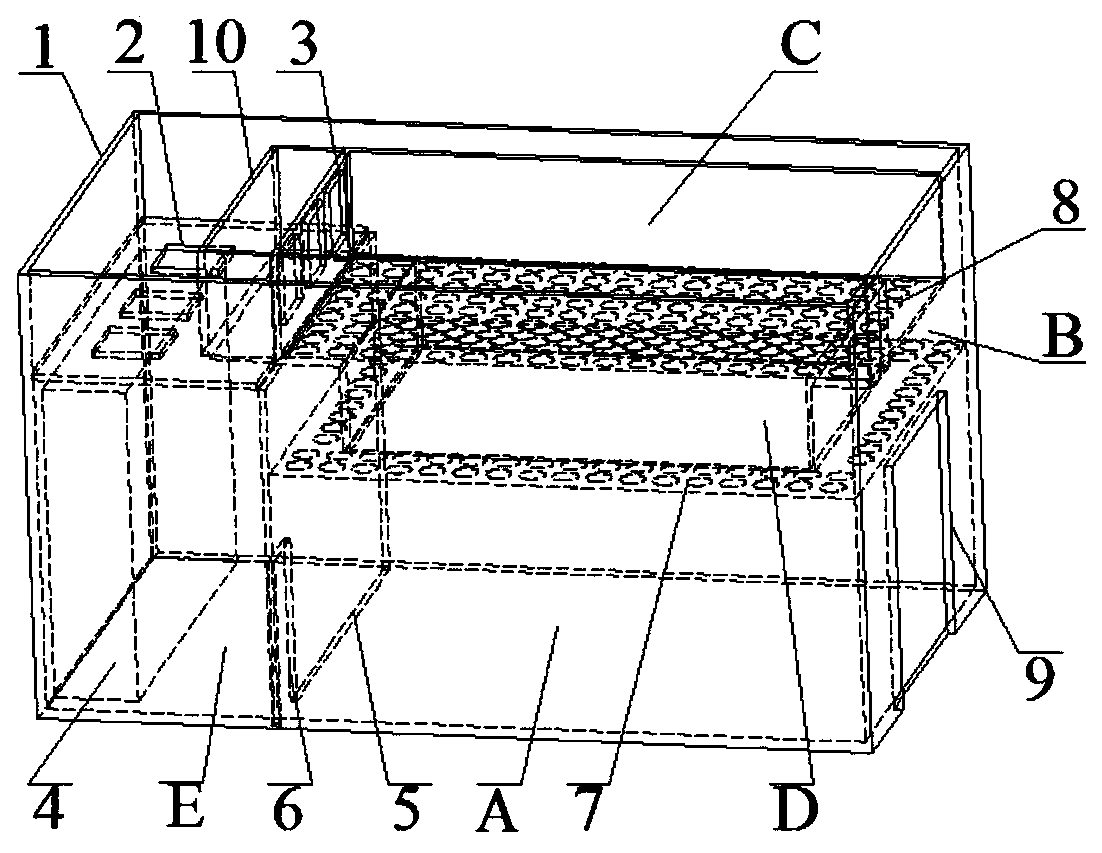

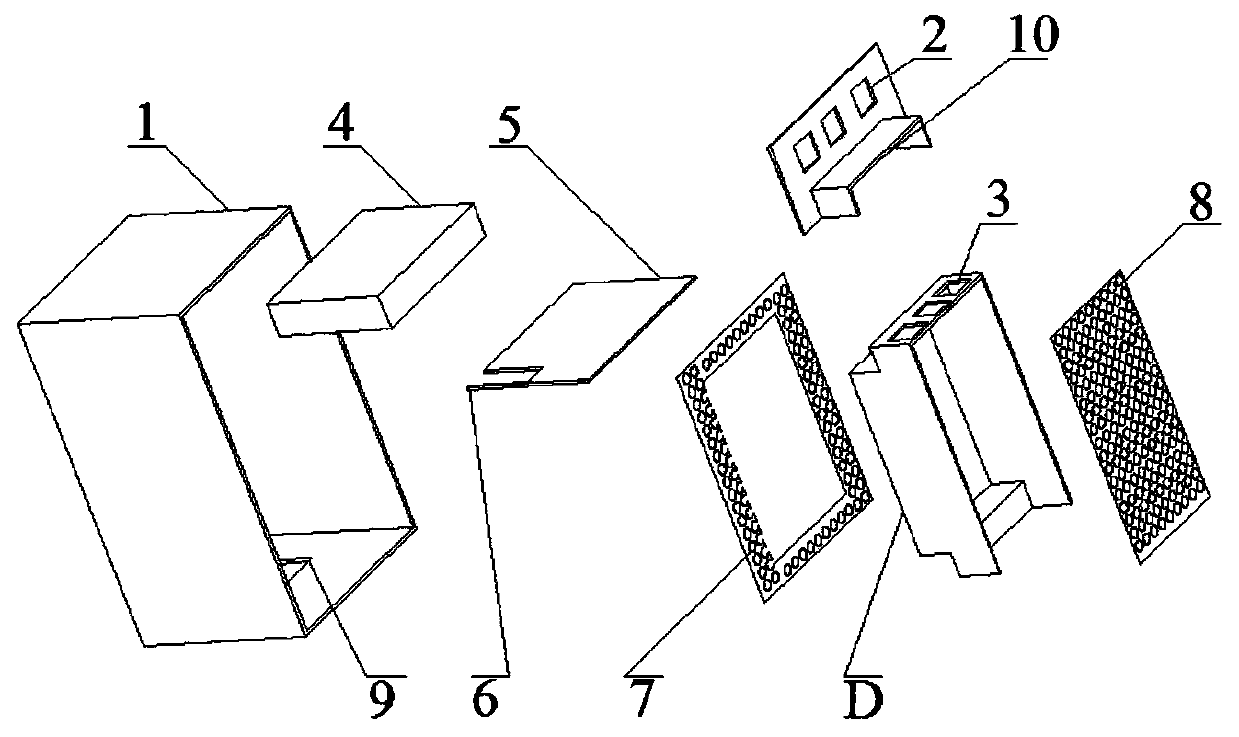

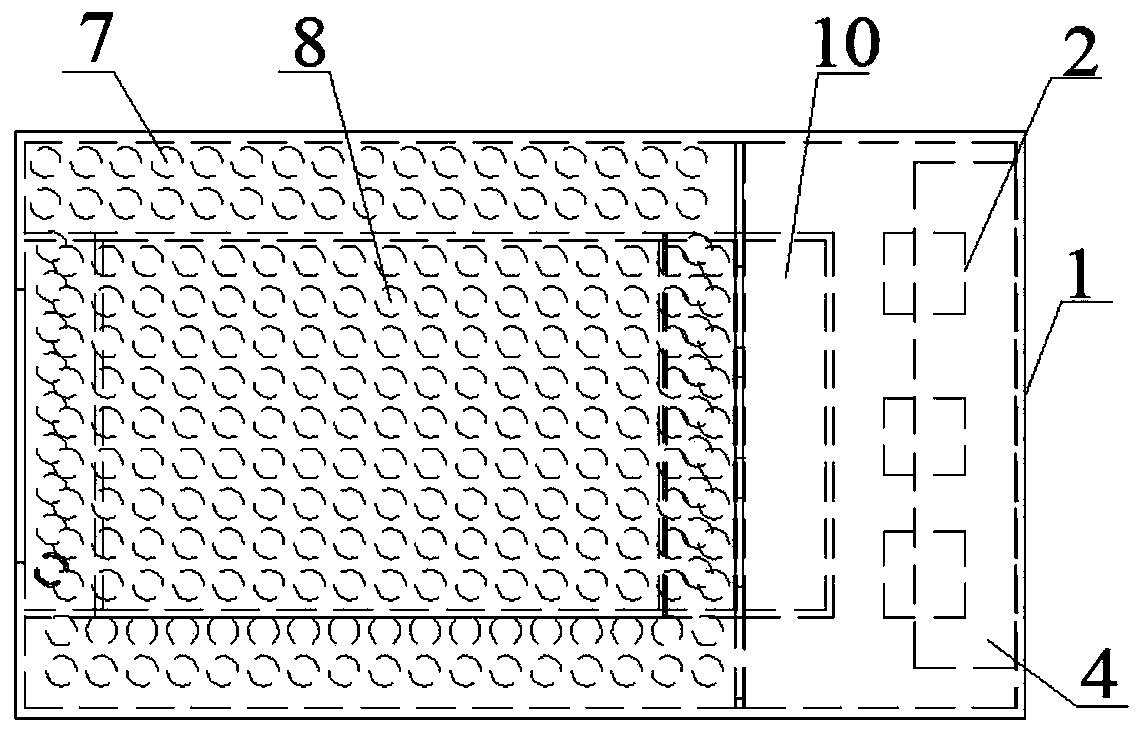

[0031] In this embodiment, one side of the air-conditioning and refrigeration equipment performance test environment chamber is the air handling unit installation section E, and the other side is the test section A of the machine under test and the return air passage located above the test section A. The air handling unit installation Section E is separated from test section A by a partition wall 5, and the top of the test section is formed by an annular air supply orifice 7, and the surface of the air supply orifice 7 is covered with air blown into the test section. The air supply through hole of the air, the ring in the middle of the air supply orifice 7 communicates with the return air passage, the return air outlet 3 at the outlet end of the return air passage communicates with the installation section E of the air handling unit, and the air supply T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com