Self-supporting-layer stranding type anti-rat-bite cable and manufacturing method thereof

A layer-twisted, anti-rat-biting technology, which is applied in the field of optical communication transmission, can solve the problems that affect the normal work of production personnel, cannot resist rodent tooth puncture, and the bending radius of the optical cable is large, and achieve excellent anti-gnawing and pecking performance , strong anti-rat bite and anti-bird peck performance, easy to use and lay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

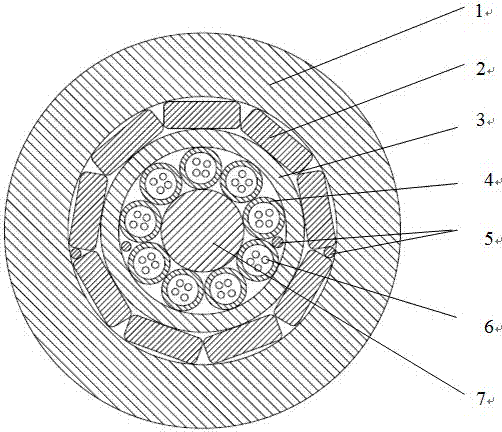

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It includes a layer-stranded cable core. The layer-stranded cable core includes a non-metallic central strength member 7 and a loose tube 4 twisted around the non-metallic central reinforcement. There are 9 loose tubes, and the loose tube is set inside There is an optical fiber 6, and it is filled with fiber paste, and the gap of the layer-stranded cable core is filled with water-blocking cable paste. The inner sheath 3 is covered outside the stranded cable core, and the anti-bite and anti-peck splicing layer 2 is covered outside the inner sheath. The anti-bite and anti-peck splicing layer is tightly packed along the circumference of the inner sheath by flat FRP strips. Arranged and spliced, the interval between adjacent flat FRP strips is 0~1.0mm, the width of the flat FRP strips is 3.0mm, the thickness is 0.7mm, and the surface is firm and smooth. Flat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com