Conical mixing container driven by multi-screw stirring

A mixing container and multi-screw technology, which is applied to mixers, mixers, mixer accessories and other directions with rotary mixing devices, can solve the problems of long time consumption, poor effect, and reduce the use efficiency of kneaders, so as to improve equipment functions, metering and other problems. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

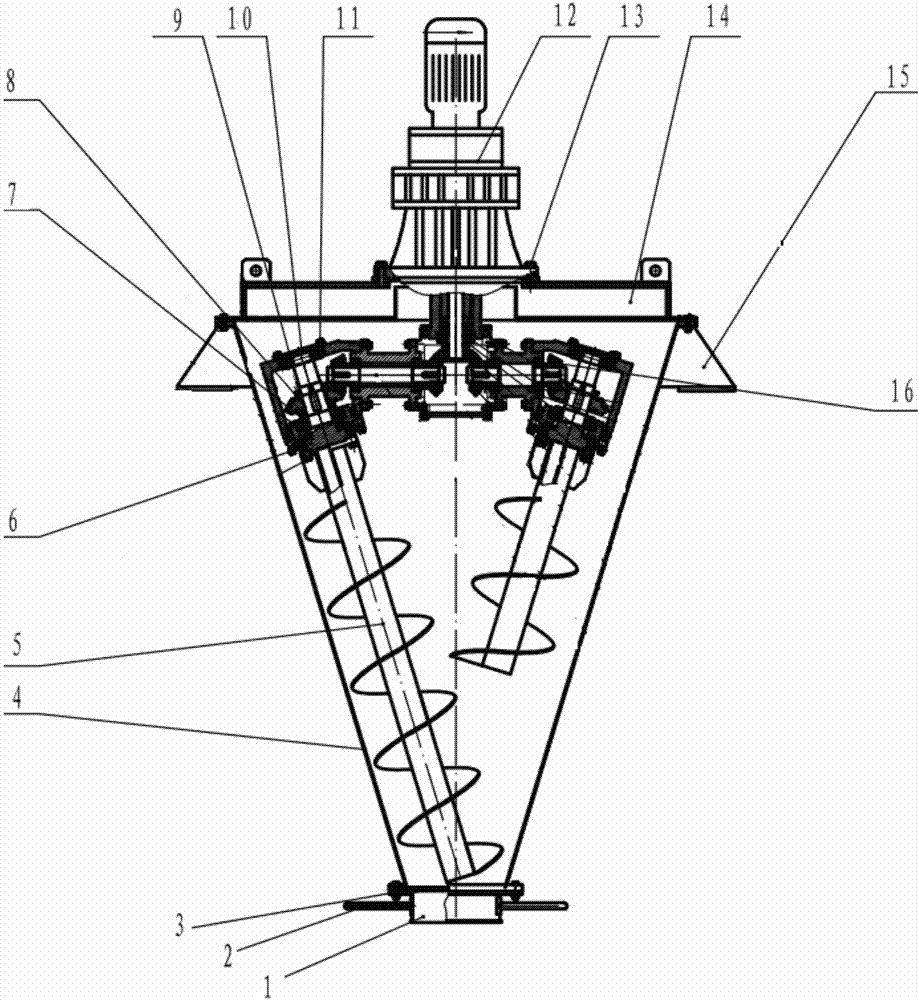

[0018] The invention provides a conical mixing container driven by multi-screw stirring, which is characterized in that: the conical mixing container driven by multi-screw stirring includes a switch, a handle, a discharge port flange, a cone, a stirring shaft, Transmission shaft, roller bearing, first gear, deep groove ball bearing, bearing gland, outer hexagon head bolt, reducer, outer hexagon head bolt, upper cover, support, second gear, reducer output gear, sealing pressure cover;

[0019] Among them: the outlet flange is arranged at the lower part of the cone, and the switch and handle are installed at the bottom of the outlet flange; the inside of the cone is equipped with a stirring shaft, which is connected to the transmission shaft, and the transmission shaft is installed on the transmission frame through roller bearings. above; the first gear is installed on the transmission shaft, the first gear and the second gear cooperate to drive, the bearing cover is installed o...

Embodiment 2

[0027] The invention provides a conical mixing container driven by multi-screw stirring, which is characterized in that: the conical mixing container driven by multi-screw stirring includes a switch, a handle, a discharge port flange, a cone, a stirring shaft, Transmission shaft, roller bearing, first gear, deep groove ball bearing, bearing gland, outer hexagon head bolt, reducer, outer hexagon head bolt, upper cover, support, second gear, reducer output gear, sealing pressure cover;

[0028] Among them: the outlet flange is arranged at the lower part of the cone, and the switch and handle are installed at the bottom of the outlet flange; the inside of the cone is equipped with a stirring shaft, which is connected to the transmission shaft, and the transmission shaft is installed on the transmission frame through roller bearings. above; the first gear is installed on the transmission shaft, the first gear and the second gear cooperate to drive, the bearing cover is installed o...

Embodiment 3

[0035] The invention provides a conical mixing container driven by multi-screw stirring, which is characterized in that: the conical mixing container driven by multi-screw stirring includes a switch, a handle, a discharge port flange, a cone, a stirring shaft, Transmission shaft, roller bearing, first gear, deep groove ball bearing, bearing gland, outer hexagon head bolt, reducer, outer hexagon head bolt, upper cover, support, second gear, reducer output gear, sealing pressure cover;

[0036] Among them: the outlet flange is arranged at the lower part of the cone, and the switch and handle are installed at the bottom of the outlet flange; the inside of the cone is equipped with a stirring shaft, which is connected to the transmission shaft, and the transmission shaft is installed on the transmission frame through roller bearings. above; the first gear is installed on the transmission shaft, and the first gear and the second gear cooperate to drive, and the bearing cover is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com